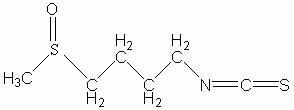

Chinese radish sulfane clathrate compound and preparation method thereof

A technology of sulforaphane and clathrates, which is applied in the field of sulforaphane clathrates and its preparation, and can solve problems such as unfavorable production and sales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 12g of sodium hydroxide (NaOH) and 250mL of deionized water into a 500ml three-necked round-bottomed flask, stir to dissolve. After the water bath was warmed up to 60° C., 120 g of β-cyclodextrin was weighed and added to the flask, and stirred to completely dissolve it. Cool down to room temperature, slowly add 80g of propylene bromide dropwise to the flask while stirring. After the dropwise addition, react at room temperature for 4 hours. After the reaction, use 1mol / L hydrochloric acid solution to neutralize the reaction solution to neutrality, filter, and wash with ethanol. Acetone extraction, dialysis and desalination, and then freeze-drying yielded 98.2 g of propenyl-β-cyclodextrin with a yield of 81.8% and a degree of substitution of 5.4.

Embodiment 2

[0039] Weigh 12g of sodium hydroxide (NaOH) and 250mL of deionized water into a 500ml three-necked round-bottomed flask, stir to dissolve. After the water bath was warmed up to 60° C., 120 g of β-cyclodextrin was weighed and added to the flask, and stirred to completely dissolve it. Cool down to room temperature, slowly add 100g of propylene bromide dropwise into the flask while stirring. After the dropwise addition, react at room temperature for 4 hours. After the reaction, use 1mol / L hydrochloric acid solution to neutralize the reaction solution to neutrality, filter, and wash with ethanol. Acetone extraction, dialysis and desalination, and then freeze-drying yielded 103.8 g of propenyl-β-cyclodextrin with a yield of 86.5% and a degree of substitution of 6.8.

Embodiment 3

[0041] Weigh 2.6 g of the propenyl-β-cyclodextrin obtained in Example 1, dissolve it in 250 mL of water for injection, stir and dissolve to obtain a saturated solution. Weigh 1.8 g of sulforaphane and dissolve it in 4 mL of absolute ethanol. Under stirring, slowly add sulforaphane absolute ethanol solution dropwise into propenyl-β-cyclodextrin aqueous solution to form a suspension, sonicate for 20-30 minutes, and continue high-speed stirring at room temperature for 24 hours. Filter with a 0.45mm microporous membrane, fill the filtrate, and freeze-dry. The white powder of propenyl-β-cyclodextrin inclusion compound of sulforaphane was obtained (the molar ratio of raw material sulforaphane to propenyl-β-cyclodextrin was about 1:0.2), and the sulforaphane in the clathrate was detected by HPLC The content of sulfane is 0.42g, and the inclusion rate is 23%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com