Method for preparing high-specific-surface-area graphene under conditions of normal pressure and low temperature

A technology with high specific surface area and low temperature conditions, applied in the field of graphene, can solve the problems of difficulty in graphene collection, unsuitable large-scale production, and high production costs, achieve broad market application prospects, overcome the limitations of vacuum or low pressure conditions, and promote peeling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1: The reaction vessel is placed in an ice-water bath. Before the reaction begins, high-purity nitrogen gas is used to remove the air in the vessel; then 90ml of concentrated nitric acid and 175ml of concentrated sulfuric acid are added, and stirred evenly to obtain a mixed acid solution; after the mixed acid solution is cooled, 10g of graphite is added, Stir evenly, then slowly add 110g potassium chlorate powder, react for 120 hours; After the reaction finishes, the solid intermediate product obtained is washed with a large amount of deionized water to remove residual sulfate ions, and then neutralized with 1% aqueous sodium hydroxide solution, Adjust the pH of the mixed solution to 7 to obtain a neutral solution of graphite oxide.

[0021] Step 2: adding an aqueous solution of hydrochloric acid to the neutral solution of graphite oxide to adjust the pH value of the mixed solution to 0, then filtering the mixed solution, and drying at 80° C. to obtain acidified gra...

Embodiment 2

[0037]This embodiment is basically the same as Embodiment 1, the difference is:

[0038] In step 2, an aqueous solution of hydrochloric acid is added to adjust the pH value of the mixed solution to 1;

[0039] In step 3, the acidified graphite oxide was put into a beaker preheated to 160° C. in atmospheric air and kept for 10 minutes.

[0040] Other operations are exactly the same as in Example 1.

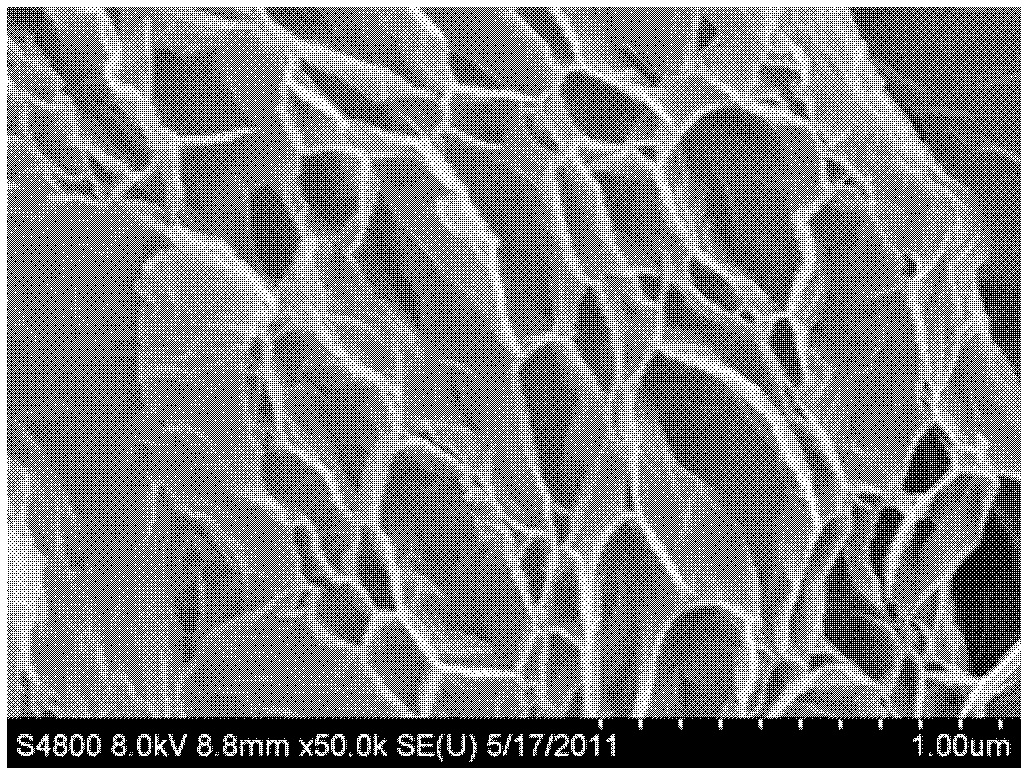

[0041] The acidified graphite oxide undergoes expansion and exfoliation under this condition to obtain a fluffy and fluffy graphene material. The test of nitrogen adsorption and desorption method shows that the specific surface area of the prepared graphene is 720m 2 / g.

Embodiment 3

[0043] This embodiment is basically the same as Embodiment 1, the difference is:

[0044] In step 2, an aqueous solution of hydrochloric acid is added to adjust the pH value of the mixed solution to 2;

[0045] In step 3, the acidified graphite oxide was put into a beaker preheated to 140° C. in atmospheric air and kept for 30 minutes.

[0046] Other operations are exactly the same as in Example 1.

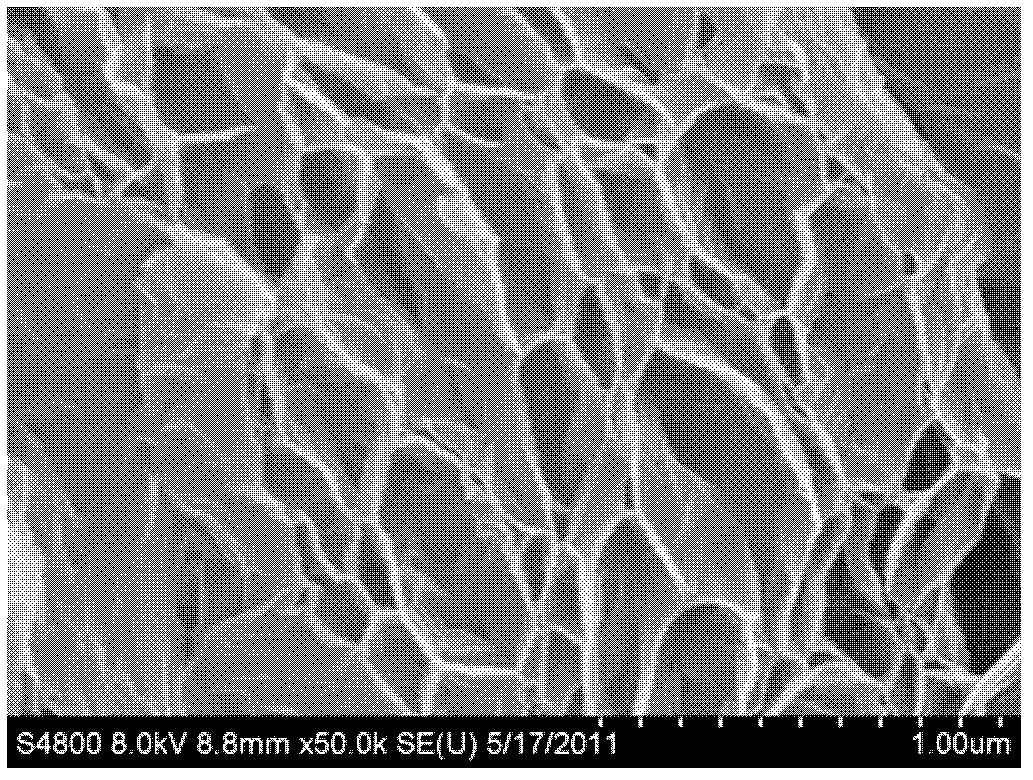

[0047] The acidified graphite oxide undergoes expansion and exfoliation under this condition to obtain a fluffy and fluffy graphene material. The test of nitrogen adsorption and desorption method shows that the specific surface area of the prepared graphene is 654m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bet specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com