Preparation method of cement raw meal grinding activator

A technology of cement raw meal and activator, which is applied in the field of building material cement clinker production additives and efficient comprehensive utilization of resources, which can solve the problems of insignificant absorption of free calcium oxide, reduced mill output, and increased power consumption of products Improve burnability, increase grinding efficiency, reduce production cost and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

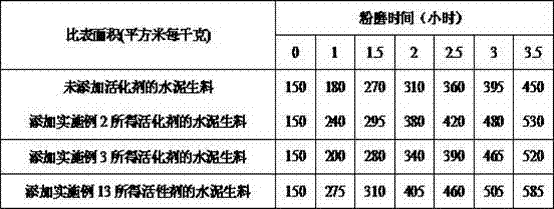

Examples

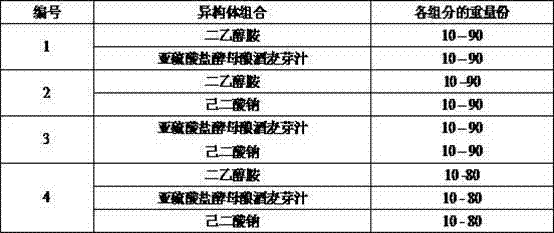

Embodiment 1

[0030] The cement raw meal grinding activator is obtained by taking diethanolamine and subjecting it to B=0.80 Tesla magnetic field magnetization treatment.

Embodiment 2

[0032] The cement raw meal grinding activator is obtained by taking sulfite yeast brewer's wort and magnetizing it with a magnetic field of B=0.80 Tesla.

Embodiment 3

[0034] The cement raw meal grinding activator is obtained by taking sodium adipate and subjecting it to B=0.80 Tesla magnetic field magnetization treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com