Novel abrasive compound and toothpaste comprising same

A technology of toothpaste and mixed powder, which is applied in the fields of dentistry, medical science, and oral care, etc. It can solve the problems that affect the penetration of flavors in toothpaste products, damage to teeth, and difficulty in dispersion, so as to enhance the ability of flavor penetration and dispersion, and alleviate wear and tear , Enhance the effect of dispersion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

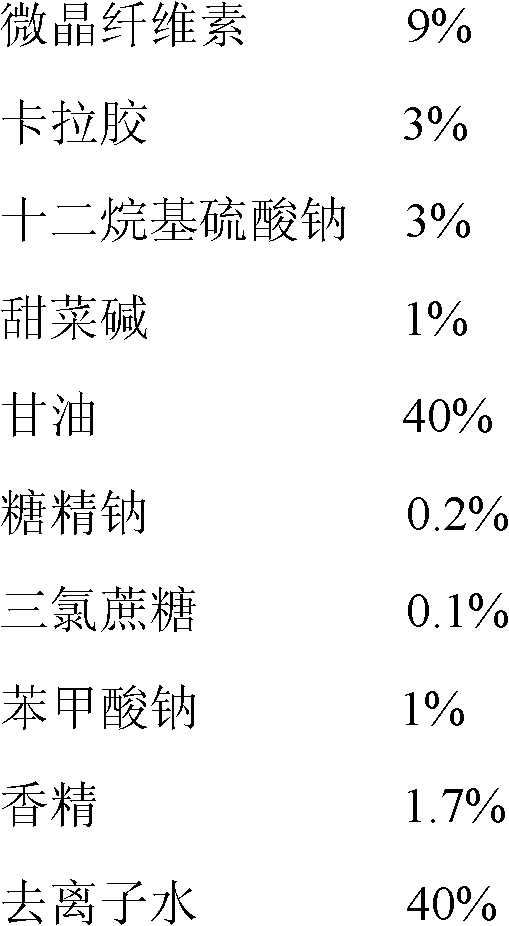

Embodiment 1

[0024]

[0025] Add sodium saccharin, sucralose, and sodium benzoate in sequence to fully dissolve in deionized water, then add glycerin and mix well to form a liquid material;

[0026] Mix the carrageenan and part of the microcrystalline cellulose evenly to form a mixed powder.

[0027] Add the mixed powder into the liquid material, and quickly disperse for 30 to 60 minutes, then add the remaining microcrystalline cellulose, and quickly disperse for 30 to 60 minutes;

[0028] Add sodium lauryl sulfate, betaine and essence in sequence and mix well to obtain a toothpaste product.

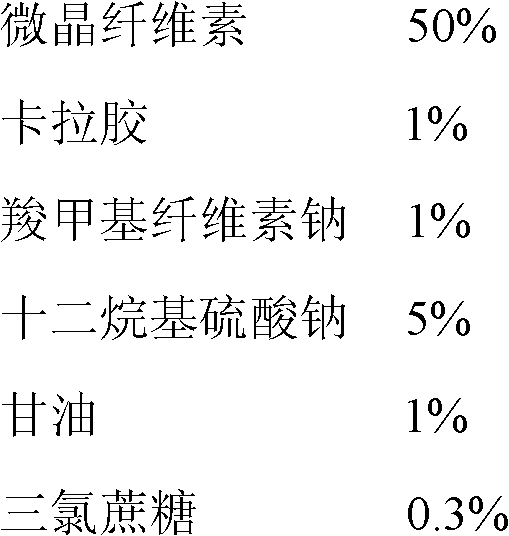

Embodiment 2

[0030]

[0031]

[0032] Add sucralose and potassium sorbate in turn to fully dissolve in deionized water, then add glycerin and mix to form a liquid material;

[0033] Carrageenan, sodium carboxymethylcellulose and part of microcrystalline cellulose are evenly mixed to form a mixed powder.

[0034] Add the mixed powder into the liquid material, and quickly disperse for 30 to 60 minutes, then add the remaining microcrystalline cellulose, and quickly disperse for 30 to 60 minutes;

[0035] Add sodium lauryl sulfate and essence in sequence and mix well to obtain the toothpaste product.

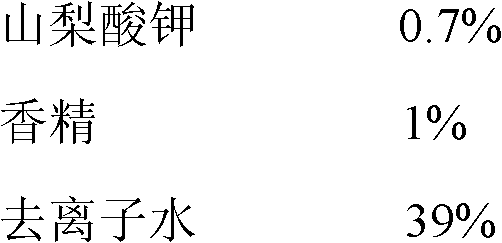

Embodiment 3

[0037]

[0038] Sucralose and polyethylene glycol are sequentially added to deionized water to fully dissolve, and then glycerin is added to mix to form a liquid material;

[0039] Mix the carrageenan and part of the microcrystalline cellulose evenly to form a mixed powder.

[0040] Add the mixed powder into the liquid material, and quickly disperse for 30 to 60 minutes, then add the remaining microcrystalline cellulose and calcium carbonate, and quickly disperse for 30 to 60 minutes;

[0041] Add betaine and essence in sequence and mix well to obtain a toothpaste product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com