Nanometer ZnO/graphene photo-catalyst and preparation method thereof

A nano-photocatalyst and photocatalyst technology, applied in the field of photocatalyst and its preparation, can solve the problems of not being widely used, complex processing process, expensive CNT and C60, etc., and achieve low cost, good photocatalytic effect, photocatalytic The effect of improving the degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

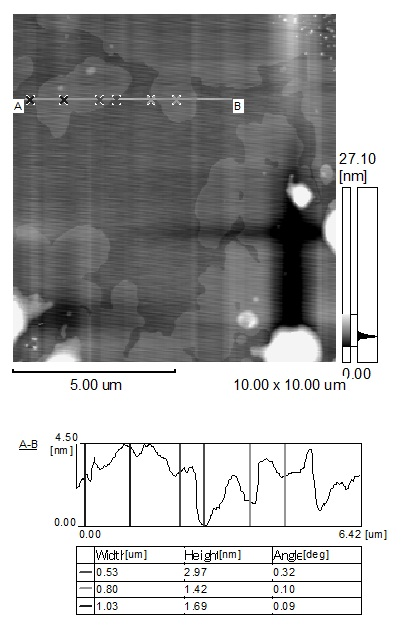

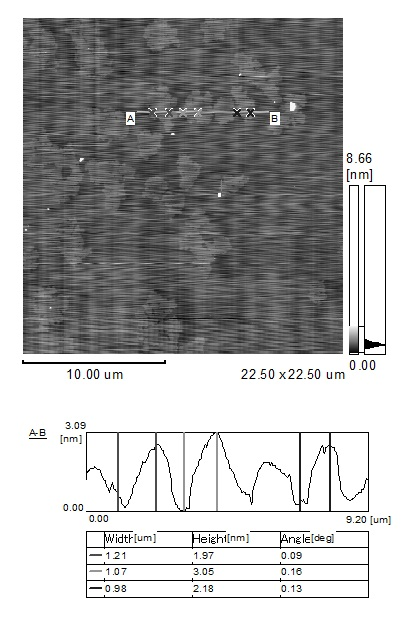

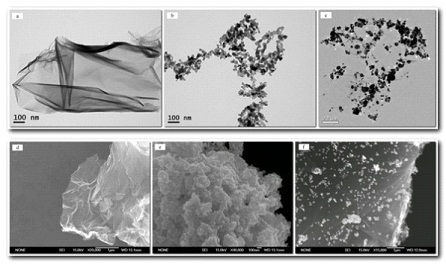

Image

Examples

preparation example Construction

[0025] The preparation method of graphite oxide please refer to (1. Hummers, W. S.; Offeman, R. E. Preparation of Graphitic

[0026] Oxide. J. Am. Chem. Soc. 1958, 80, 1339;

[0027] 2. Wang, Y.; Li, Y. M.; Tang, L. H.; Lu, J.; Li, J. H. Application ofGraphene-Modi?ed Electrode for Selective Detection of Dopamine. Electrochem. Commun. 2009, 11, 889.).

[0028] The preparation method of the graphite oxide of the present embodiment is: 2.5g P 2 o 5 , 2.5 g K 2 S 2 o 8 Add to Erlenmeyer flask, shake well, slowly add H 2 SO 4 , heated to 80°C in an oil bath, and then added 3 g Graphite powder, keep the temperature at 80°C for 4.5 h; cool at room temperature, use 500 ml Stir for 30 min after diluting with water, then stand still for 20 h; filter with suction and dry; 120 ml H 2 SO 4 Add it into the Erlenmeyer flask, add the above filter residue, and slowly add 15 g KMnO 4 , the temperature should be lower than 20°C, then put the Erlenmeyer flask into an oil b...

Embodiment 1

[0030] 1.1 Reagents and Instruments

[0031] Graphite powder (graphite powder, C.P., Sinopharm Chemical Reagent Co., Ltd.), P 2 o 5 (A.R., Sinopharm Chemical Reagent Co., Ltd.), H 2 SO 4 (G.R., Sinopharm Chemical Reagent Co., Ltd.), K 2 S 2 o 8 (A.R., Sinopharm Chemical Reagent Co., Ltd.), KMnO 4 (A.R., Sinopharm Chemical Reagent Co., Ltd.), H 2 o 2 (A.R., Sinopharm Chemical Reagent Co., Ltd.), ZnNO 3 (A.P., Sinopharm Chemical Reagent Co., Ltd.), (NH 4 ) 2 CO 3 (A.P., Sinopharm Chemical Reagent Co., Ltd.), and the experimental water was deionized water. The main instruments are CR21GⅡ high-speed refrigerated centrifuge (Hitachi, Japan), U-3010 UV-visible spectrophotometer (Hitachi, Japan), JEOL-200CX transmission electron microscope (Japan Electronics Co., Ltd.), JSM-2010F X-ray powder Diffraction instrument (JEOL Ltd.), JSM-6700F high-resolution scanning electron microscope (JEOL Ltd.), AVATAR 370 infrared spectrophotometer (Thermo Nicolet, USA); photocatalytic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com