Dielectric adjustable compound film for stress auxiliary modulation and preparation method thereof

A composite film and stress technology, applied in chemical instruments and methods, components of fixed capacitors, fixed capacitor dielectrics, etc., can solve problems such as unreachable and compositional deviations, and achieve excellent temperature stability, excellent composition stability and temperature The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

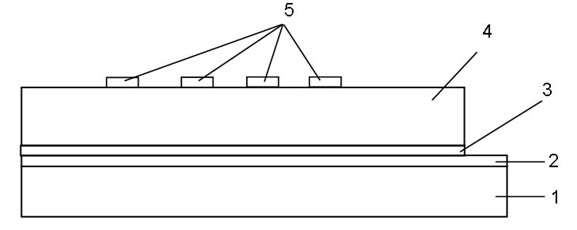

preparation example Construction

[0033] In the preparation of composite film of the present invention, adopted general-purpose sol-gel method, specifically as follows:

[0034] 1) Preparation of doped PT sol: heat the mixed solution of acetic acid and ethylene glycol methyl ether as a solvent (the volume percentage of acetic acid is 80%~90%) to 40~70 ℃, and then put in lead acetate powder, zinc acetate Powder (or ferric nitrate powder, cobalt chloride powder), liquid butyl titanate, stirring continuously for 12 to 24 hours to obtain doped PT sol. The molar ratio of Pb and Ti elements is 1:1, the Pb concentration is controlled at 0.03-0.1 mol / L, and the molar ratio of Zn (or Fe, Co) to Pb elements is: 0.01-0.03:1.

[0035] 2) Using the sol prepared in step 1), plate a doped PT stress-inducing layer on the ITO glass substrate by dipping and pulling. The substrate is immersed in the sol for a moment, and after staying for 10 to 25 seconds, the substrate is pulled out of the sol at a pulling speed of 2 to 6 cm / m...

Embodiment 1

[0042] Heat the mixed solution of acetic acid and ethylene glycol methyl ether as a solvent (the volume percentage of acetic acid is 80%) to 40°C, add lead acetate powder, zinc acetate powder, and liquid butyl titanate in sequence, and continue stirring for 12 hours to obtain Doped with PT sol. The molar concentrations of Pb and Ti elements are both controlled to be 0.03 mol / L, and the molar ratio of Zn and Pb elements is 1:100 to form Zn with a concentration of 0.03 mol / L. 2+ Doped with PT sol.

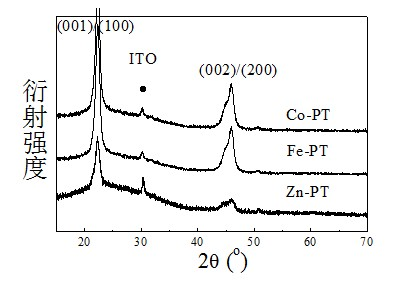

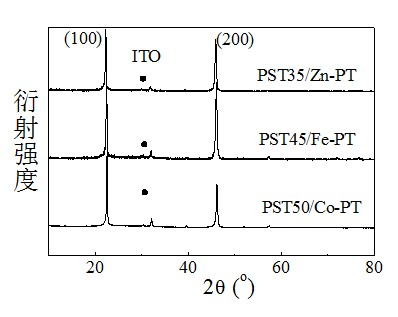

[0043] Apply the above-mentioned Zn-doped PT sol, immerse the ITO / glass substrate, pull the substrate at a pulling speed of 2 cm / min after staying for 10 minutes, and place the sample horizontally to dry naturally to obtain a dry film; directly in a furnace at 550 °C After rapid heat treatment for 4 min, it was quickly taken out and cooled naturally in air at room temperature to obtain a Zn-doped PT stress-inducing layer. XRD pattern of Zn-doped PT stress-inducing layer figure 2 ...

Embodiment 2

[0047] Heat the mixed solution of acetic acid and ethylene glycol methyl ether as a solvent (the volume percentage of acetic acid is 85%) to 40°C, add lead acetate powder, iron nitrate powder, and liquid butyl titanate in sequence, and continue stirring for 18 hours to obtain Doped with PT sol. The molar concentrations of Pb and Ti elements are both controlled to be 0.07 mol / L, and the molar ratio of Fe and Pb elements is 2:100, forming Fe with a concentration of 0.07 mol / L 3+ Doped with PT sol.

[0048] Apply the above-mentioned Fe-doped PT sol, immerse the ITO / glass substrate, pull the substrate at a pulling speed of 4 cm / min after staying for 20 seconds, and place the sample horizontally to dry naturally to obtain a dry film; directly in a furnace at 580 °C After rapid heat treatment for 6 min, it was quickly taken out and cooled naturally in air at room temperature to obtain a Fe-doped PT stress-inducing layer. XRD pattern of Fe-doped PT stress-inducing layer figure 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com