Barium titanyl oxalate particle, method for preparing the same and method for preparing barium titanate

A technology of barium titanyl oxalate and a manufacturing method, which are applied in the preparation of carboxylate, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of high powder price, high price, complex synthesis process, etc. The effect of high performance and crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

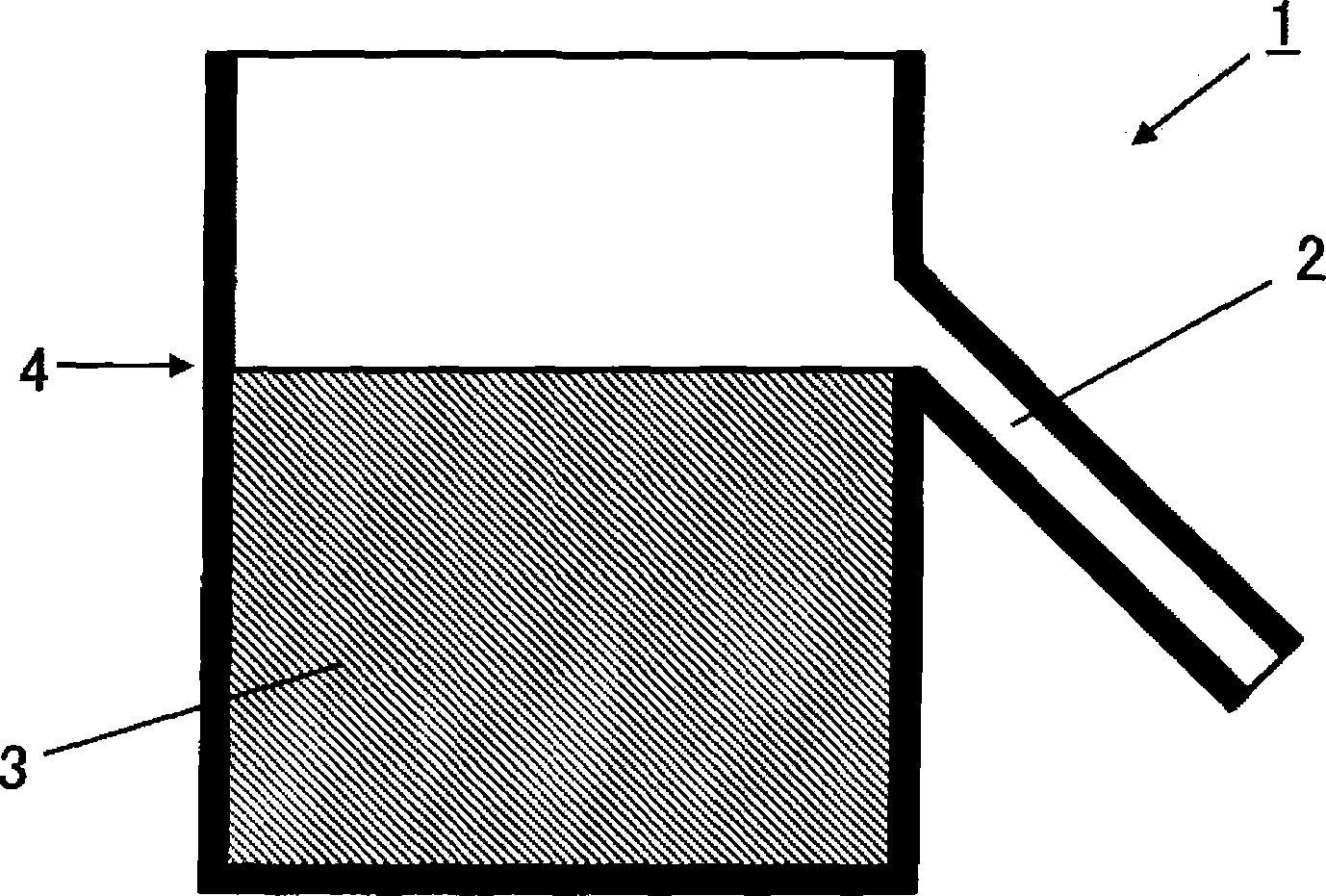

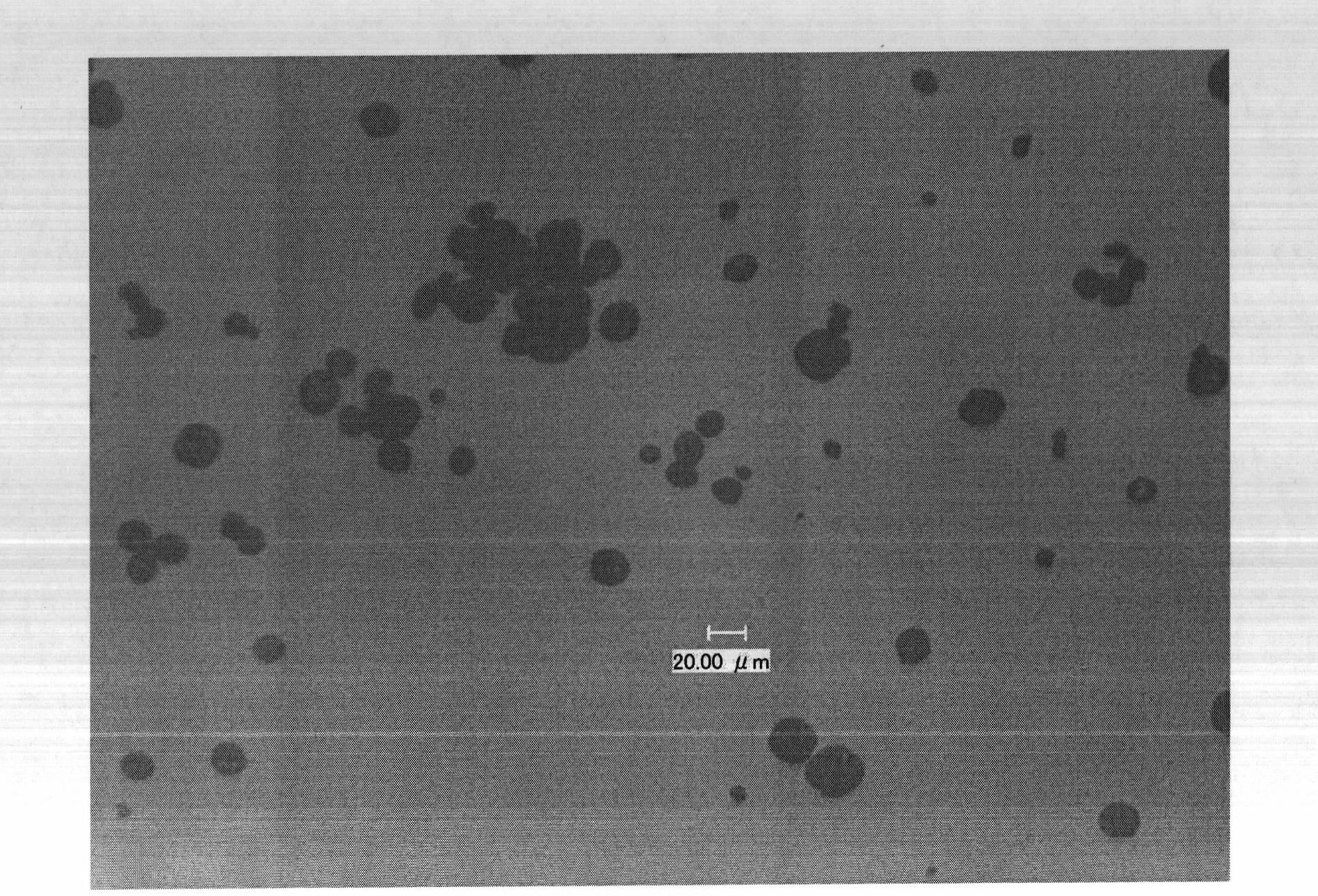

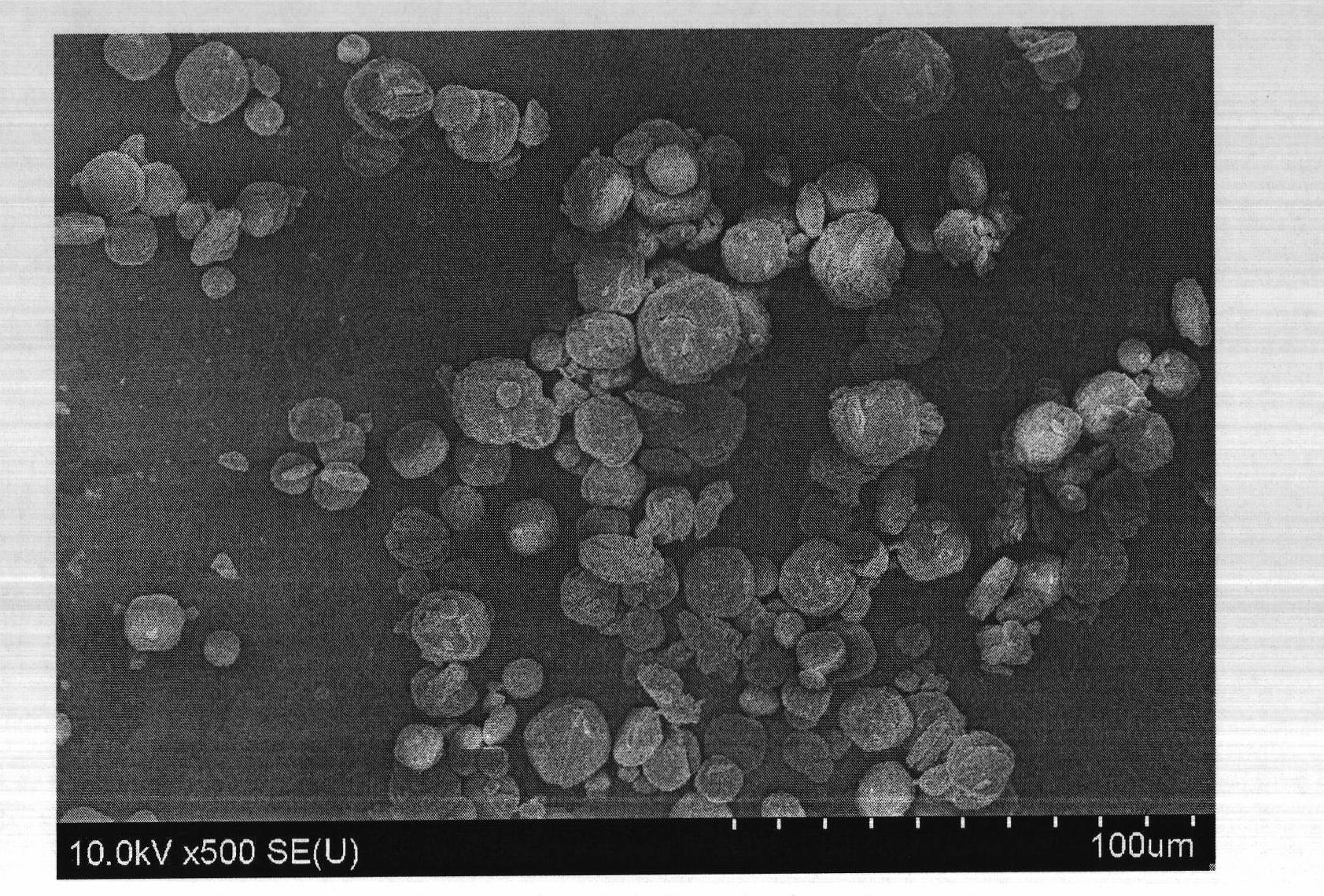

[0092] In the aqueous solution that has added 250g oxalic acid 2 hydrates in 2154g water, mix 332g Ti concentration and be the titanium tetrachloride aqueous solution of 2.56mol / L, make oxalic acid be 0.79mol / L, Ti be 0.26mol / L and mix oxalic acid and tetrachloride in water An aqueous solution (A1 liquid) obtained by titanium chloride. That is, the molar ratio of the oxalate ion to the Ti element in the A1 liquid was 3.1. Separately, 195 g of barium chloride was dissolved in 963 g of water to prepare an aqueous barium chloride solution (B1 liquid) with Ba of 0.80 mol / L. Next, pure water was added to the reaction container, and the temperature was maintained at 35° C., and the A1 liquid and the B1 liquid were supplied to the reaction container at a rate of 0.9 L / hour and 0.4 L / hour while stirring. That is, the ratio of the supply rate of the Ba element to the supply rate of the Ti element to the reaction vessel was 1.3, and the residence time of the formed barium titanyl oxala...

reference example 1

[0101] Barium titanyl oxalate particles were obtained by performing the reaction under the same operation and conditions as in Example 1, except that the production reaction of barium titanyl oxalate was set at 55°C. In addition, as a result of calculating the reaction rate of Ba and Ti in the same manner as in Example 1, Ba was 70% and Ti was 95%.

[0102] Therefore, compared with Example 1, it can be seen that there are many components of Ba and Ti remaining unreacted, and the reaction efficiency and yield are lowered.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com