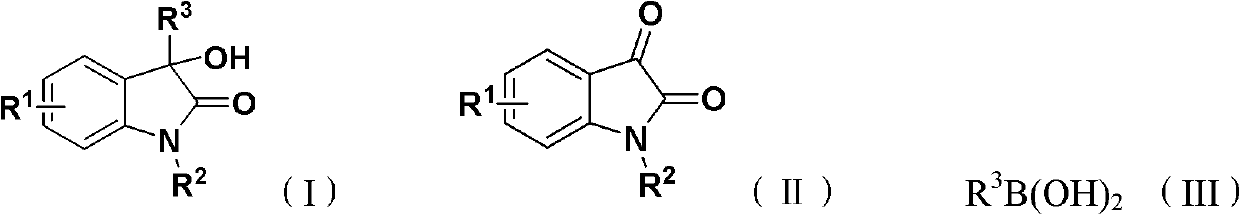

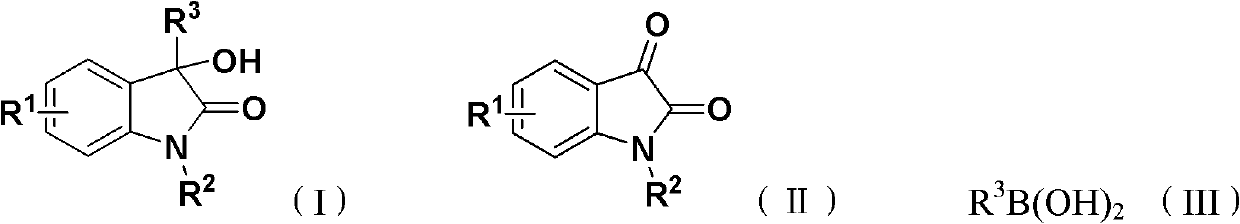

Method for synthesizing 3-hydroxy-3-arylindole-2-one derivative

A synthesis method and derivative technology, applied in the field of chemical synthesis of 3-hydroxy-3-arylindol-2-one derivatives, can solve the problems of strict structure requirements, difficulty in obtaining, expensive catalysts, etc., and achieve product quality Good, cheap, large implementation value and the effect of social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

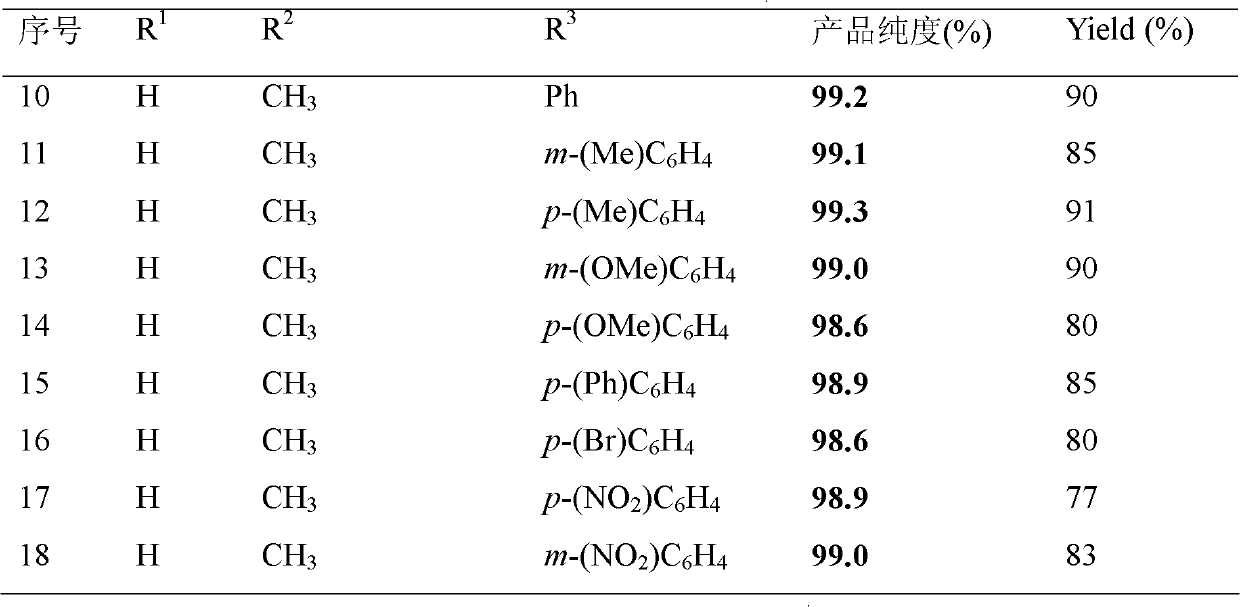

Examples

Embodiment 1

[0024] N-methyl isatin, phenylboronic acid, copper trifluoromethanesulfonate, o-phenanthroline monohydrate, and lithium hydroxide monohydrate are charged at a material ratio of 1.0:2.0:0.05:0.1:3.0, and N-methyl Isatin 16.1g (0.1mol); Phenylboronic acid 24.4g (0.2mol); Copper trifluoromethanesulfonate 1.8g (0.005mol); O-phenanthroline monohydrate 2.0g (0.01mol); Lithium hydroxide monohydrate 12.6 g (0.3mol); Organic solvent is xylene 241.5g, and its total consumption is 15 times of N-methyl isatin quality.

[0025] Put N-methylisatin, phenylboronic acid, copper trifluoromethanesulfonate, phenanthroline monohydrate, and lithium hydroxide monohydrate into the reaction kettle, add xylene to dissolve, the reaction temperature is 100°C, and react after 48 hours Finish.

[0026] After the reaction, the organic solvent was recovered by distillation under reduced pressure, and the solid remaining in the reaction flask was recrystallized from ethanol dried with calcium chloride to obt...

Embodiment 2

[0029] N-methylisatin, phenylboronic acid, copper trifluoromethanesulfonate, 4,4'-dimethyl-2,2'-bipyridine, and lithium hydroxide monohydrate have a material ratio of 1.0:2.0:0.05 : 0.1: 3.0 feeding, N-methylisatin 16.1g (0.1mol); phenylboronic acid 24.4g (0.2mol); copper trifluoromethanesulfonate 0.92g (0.005mol); 4,4'-dimethyl- 2,2'-bipyridine 2.08g (0.01mol); Lithium hydroxide monohydrate 12.6g (0.3mol); The organic solvent is 241.5g xylene, the total amount of which is 15 times the mass of N-methylisatin.

[0030] The rest are the same as in Example 1, and the obtained product N-methyl-3-hydroxyl-3-phenylindol-2-one is 11.9 g, the yield is 50%, and the purity is 98.5%.

Embodiment 3

[0032] N-methyl isatin, phenylboronic acid, copper trifluoromethanesulfonate, o-phenanthroline monohydrate, and cesium carbonate are charged with a material ratio of 1.0: 2.0: 0.05: 0.1: 3.0, N-methyl isatin 16.1 g (0.1mol); 24.4g (0.2mol) of phenylboronic acid; 1.8g (0.005mol) of copper triflate; 2.0g (0.01mol) of phenanthroline monohydrate; 97.8g (0.3mol) of cesium carbonate; Organic solvent is xylene 241.5g, and its total consumption is 15 times of N-methyl isatin quality.

[0033] The rest are the same as in Example 1, and the obtained product N-methyl-3-hydroxyl-3-phenylindol-2-one is 13.9 g, the yield is 58%, and the purity is 98.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com