Application of polyurethane prepolymer to preparation of wood powder/polrvinyl chloride composite material

A technology of polyurethane prepolymer and polyvinyl chloride, applied in the field of polymer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The ratio (NCO / OH) of the number of moles of isocyanate to the number of moles of hydroxyl groups was 2.0. PBA (240 parts) was added to a three-necked flask (500 mL) equipped with a stirrer. The PBA was dried under vacuum in an oil bath at 110°C with stirring. After 30 minutes, the vacuum was removed. After the reaction system was cooled to 70° C., MDI (60 parts) was added within 5 minutes while stirring. After adding MDI for 15 minutes, the system oil bath was kept at 80°C. Subsequently, the system was continuously reacted for 60 minutes under the condition of stirring and vacuuming to obtain a white polyurethane prepolymer, which was named PBAPU. The "parts" in the present invention refer to parts by weight.

Embodiment 2

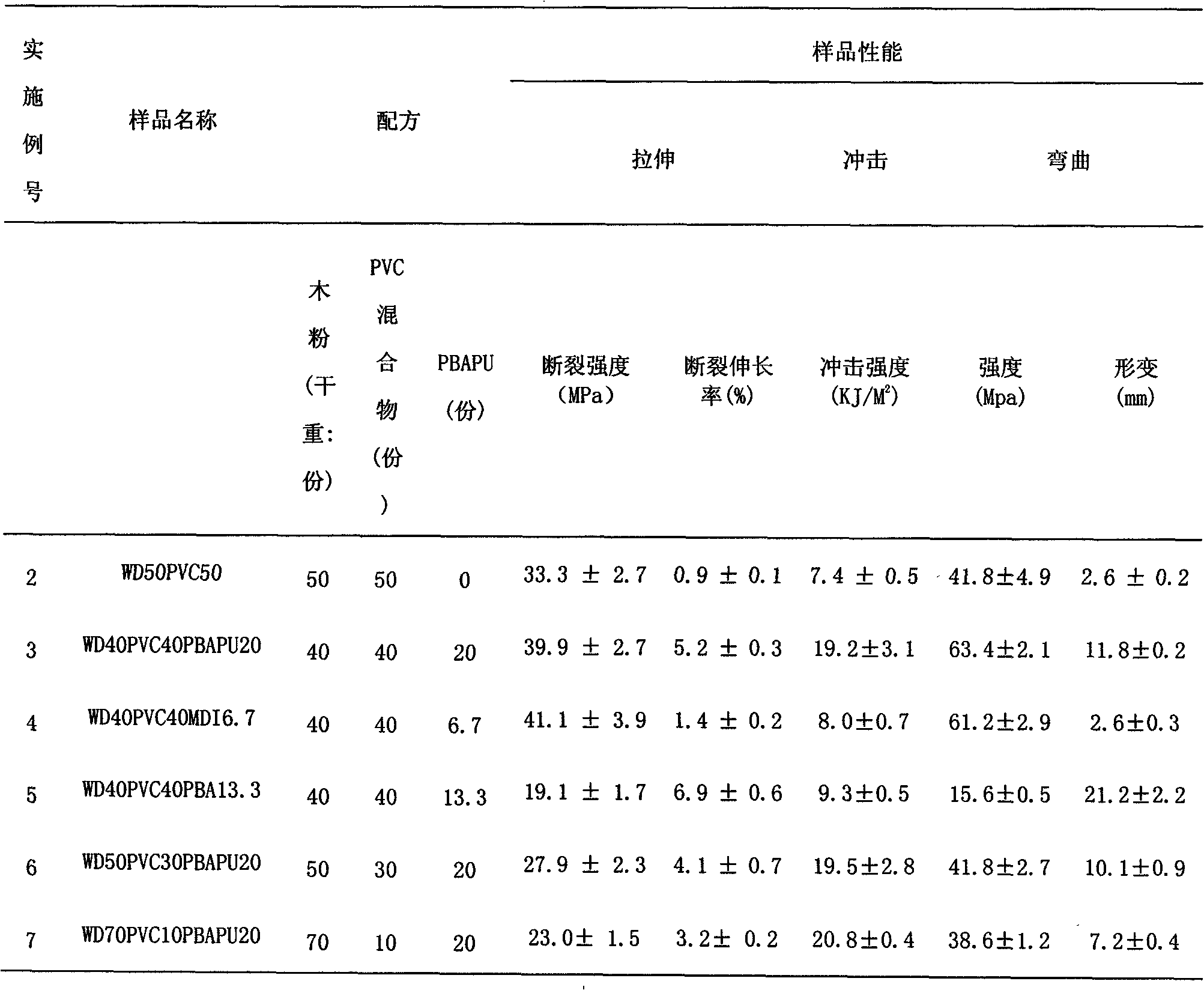

[0029]The PVC mixture contained PVC (100 parts), stabilizer (3.8 parts), ACR-401 (3.8 parts) and polyethylene wax (0.4 parts). The above PVC mixture (50 parts) and cedar wood powder (50 parts) were mixed together at room temperature with an ordinary mixer to prepare a premix. The premix is fed into the internal mixer, the heating section of the internal mixer is set at 160°C / 160°C / 160°C, and the speed is 100rpm. After 10 minutes the reaction was stopped and material was removed. The composite material after banburying is named WD50PVC50. The pellets were hot-pressed at 170°C for 5 minutes to make tablets and samples, and then subjected to tensile test, impact test and bending test respectively. The mechanical performance data of the test are shown in Table 1.

Embodiment 3

[0031] The formula is changed to: Chinese fir powder, 40 parts; PBAPU prepared by Example 1, 20 parts; the PVC mixture shown in Example 2 is 40 parts, and the processing conditions are the same as in Example 2. The composite material after banburying is called WD40PVC40PBAPU20. The mechanical performance data of the test are shown in Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com