Sintering synthesis method of metal-based ceramic material Al-Zr2P2WO12 having controllable thermal expansion coefficient

A technology of thermal expansion coefficient and ceramic materials, which is applied in the field of sintering synthesis of metal-based ceramic materials Al-Zr2P2WO12, to achieve the effects of low sintering temperature, fast speed and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

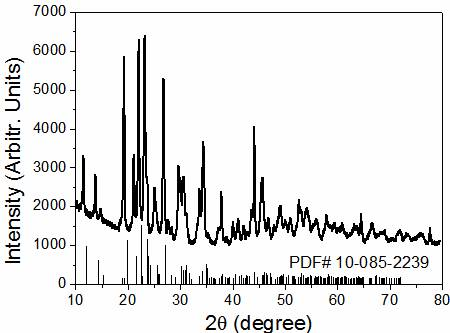

[0031] To analyze pure ZrOCl 2 ·8H 2 O, 5(NH 4 ) 2 O·12WO 3 ·5H 2 O and NH 4 h 2 PO 4 Preparation of Zr as raw material 2 P 2 WO 12 Negative expansion ceramic powder. According to the target product Zr 2 P 2 WO 12 Medium stoichiometric ratio (molar ratio) Zr: P: W = 2: 2: 1 Weigh ZrOCl 2 ·8H 2 O, NH 4 h 2 PO 4 and 5(NH 4 ) 2 O·12WO 3 ·5H 2 O, respectively add water to dissolve and prepare the corresponding solution, mix NH 4 h 2 PO 4 solution and ZrOCl 2 ·8H 2 O solution was added dropwise to 5(NH 4 ) 2 O·12WO 3 ·5H 2 In the O solution, the mol ratio of Zr:P:W in the mixed solution is 2: 2: 1 to obtain a turbid solution. with HCl and NH 3 ·H 2 O adjust the pH value to 9, continue to stir for 3 hours until uniform, leave to stand and age for 4 hours, separate layers, remove the supernatant, and the precipitate is at 120 o C drying 5h, at 900 o C sintered for 6h to get Zr 2 P 2 WO 12 Negative expansion ceramic powder. For the phase analysis...

Embodiment 2

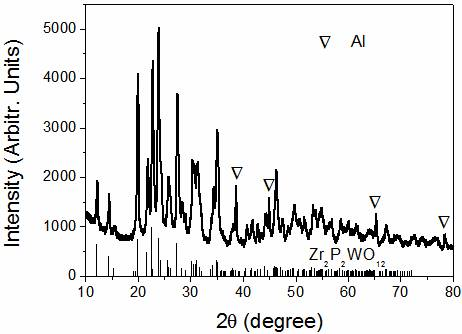

[0033] The Zr that embodiment 1 prepares 2 P 2 WO 12 Negative expansion ceramic powder mixed with commercial aluminum powder to prepare metal matrix composite ceramic Al-Zr with controllable coefficient of thermal expansion 2 P 2 WO 12 . Combining commercial Al powder with Zr 2 P 2 WO 12 The mass ratio of the ceramic powder is 0.1186, and the total mass is 2 g. Put it into a mortar and grind it for 1-3 h to mix evenly. Then press it into a cylinder with a diameter of 10 mm and a height of 15 mm with a tablet press at a pressure of 200 MPa. Placed in a low temperature box furnace to heat up to the sintering temperature of 840 o C, the sintering time is 1 h. figure 2 Is the product Al-Zr 2 P 2 WO 12 XRD pattern, XRD pattern with orthorhombic phase of Zr 2 P 2 WO 12 (PDF# 01-085-2239) corresponds exactly to the diffraction peak of elemental Al, indicating that the prepared material is Al-Zr 2 P 2 WO 12 metal matrix composite ceramics, no Zr 2 P 2 WO 12 break...

Embodiment 3

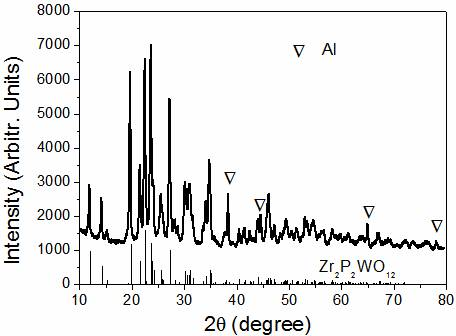

[0035] The difference with Example 2 is: the preparation of Zr 2 P 2 WO 12 During the negative expansion ceramic powder, the steps are basically the same as in Example 1, except that the sintering temperature is 950 o C, sintering time 5h. Commercial Al powder with Zr 2 P 2 WO 12 The mass ratio of the ceramic powder is 0.1286. Placed in a low temperature box furnace to heat up to the sintering temperature of 800 o C, the sintering time is 2 h. made of Al-Zr 2 P 2 WO 12 For the corresponding X-ray diffraction phase analysis see image 3 , XRD pattern with orthorhombic Zr 2 P 2 WO 12 (PDF# 01-085-2239) corresponds exactly to the diffraction peak of elemental Al, indicating that the prepared material is Al-Zr 2 P 2 WO 12 metal matrix composite ceramics, no Zr 2 P 2 WO 12 break down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com