Superfine composite fiber film, preparation method and use thereof

A technology of ultra-fine composite fibers and fiber membranes, applied in the fields of medical science, textiles and papermaking, bandages, etc., can solve problems such as dysfunction, artificial materials stay in the body, cannot be removed, etc., and achieve high porosity and suitable tissue adhesion. The effect of convenient performance and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Solution preparation: PLGA (molecular weight is 80,000, wherein the molar ratio of lactide to glycolide is 95:5) and PELA (molecular weight is 10,000, wherein the molar ratio of polylactide to polyethylene glycol Ratio is 2: 8) is dissolved in the mixed solvent of N, N dimethylformamide (DMF) and acetone (volume ratio is 5: 5), obtains the mixing of PLGA and PELA that total polymer mass volume concentration is 50% solution. In the solution, the mass ratio of PLGA to PELA is 95:5.

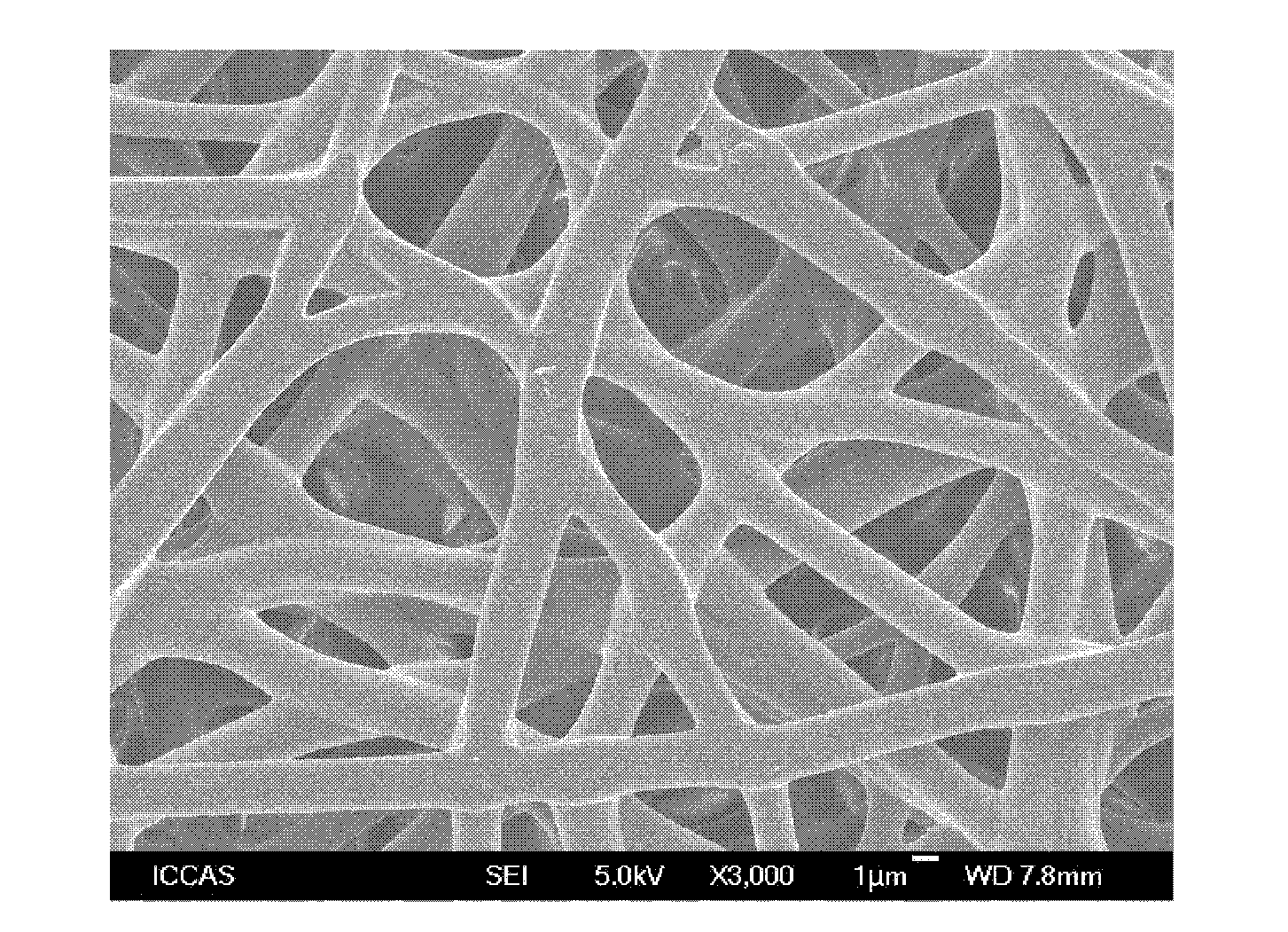

[0032] (2) Electrospinning: the PLGA solution obtained in step (1) is placed in the feeding syringe of the electrospinning equipment. Adjust the distance between the spinneret and the roller to 12cm, the ambient temperature for spinning is 25°C, and the air velocity in the environment is controlled at 0.5-0.8m 3 / hr, turn on the high-voltage power supply and the feeding syringe pump, adjust the voltage to 20kV, and the feeding speed of the solution is 20 μl / min, and perform spinning. Th...

Embodiment 2

[0035] (1) Solution preparation: mix PLGA (molecular weight of 200,000, wherein the molar ratio of lactide to glycolide is 3:1) and PELA (molecular weight of 10,000, wherein the molar ratio of polylactide to polyethylene glycol Ratio is 50:50) is dissolved in the mixed solvent of N,N dimethylformamide (DMF) and acetone (volume ratio is 9:1), obtains the mixing of PLGA and PELA that total polymer mass volume concentration is 35% solution. In the solution, the mass ratio of PLGA to PELA is 80:20.

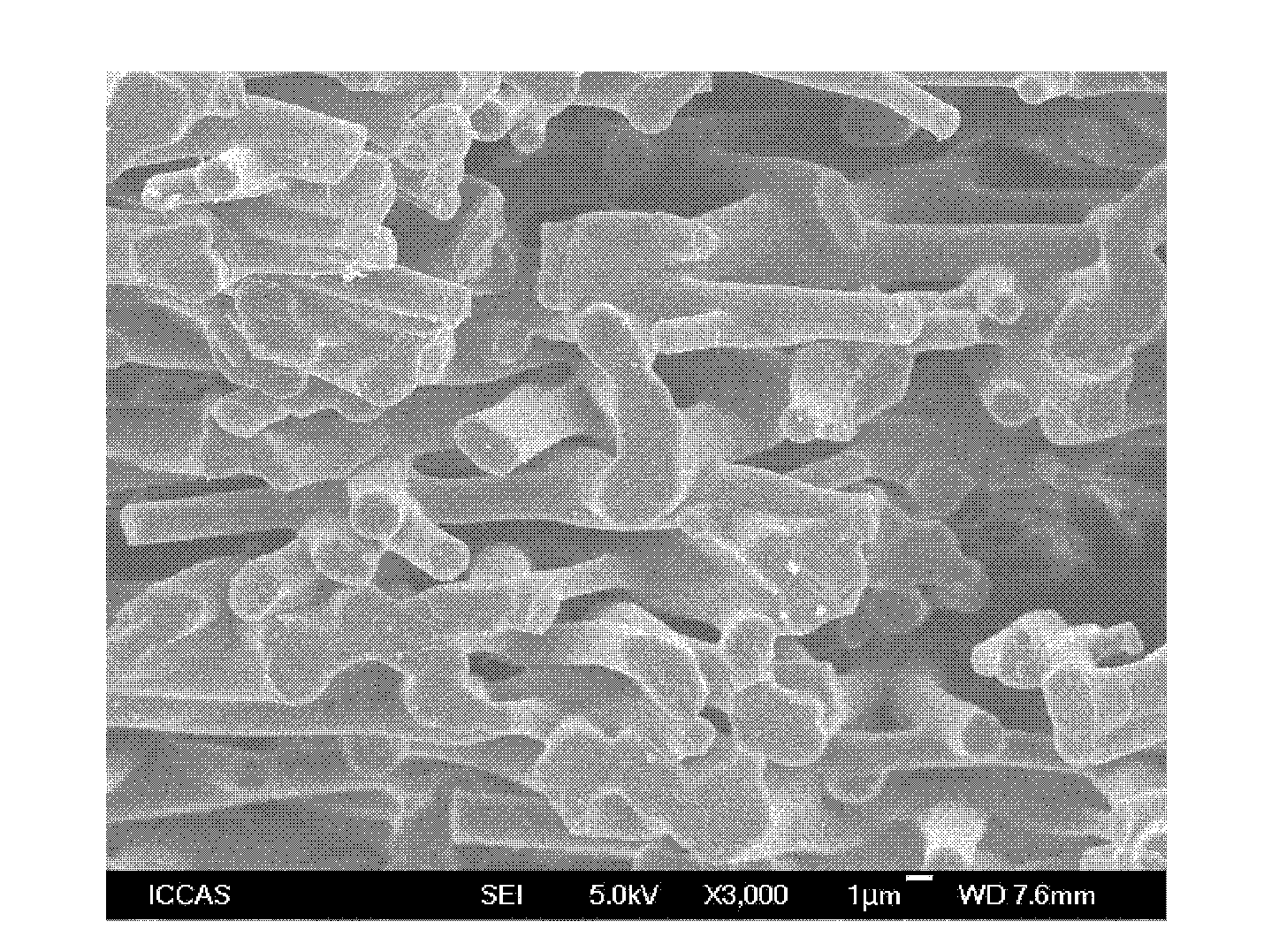

[0036] (2) Electrospinning: the PLGA solution obtained in step (1) is placed in the feeding syringe of the electrospinning equipment. Adjust the distance between the spinneret and the roller to 12cm, the ambient temperature for spinning is 25°C, and the air velocity in the environment is controlled at 0.5-0.8m 3 / hr, turn on the high-voltage power supply and the feeding syringe pump, adjust the voltage to 20kV, and the feeding speed of the solution is 20 μl / min, and perform spinning...

Embodiment 3

[0039] (1) Solution preparation: PLGA (molecular weight is 40,000, wherein the molar ratio of lactide to glycolide is 3:1) and PELA (molecular weight is 80,000, wherein the molar ratio of polylactide to polyethylene glycol Ratio is 9: 1) is dissolved in the mixed solvent of N, N dimethylformamide (DMF) and acetone (volume ratio is 1: 9), obtains the mixing of PLGA and PELA that total polymer mass volume concentration is 45wt% solution. In the solution, the mass ratio of PLGA to PELA is 75:25.

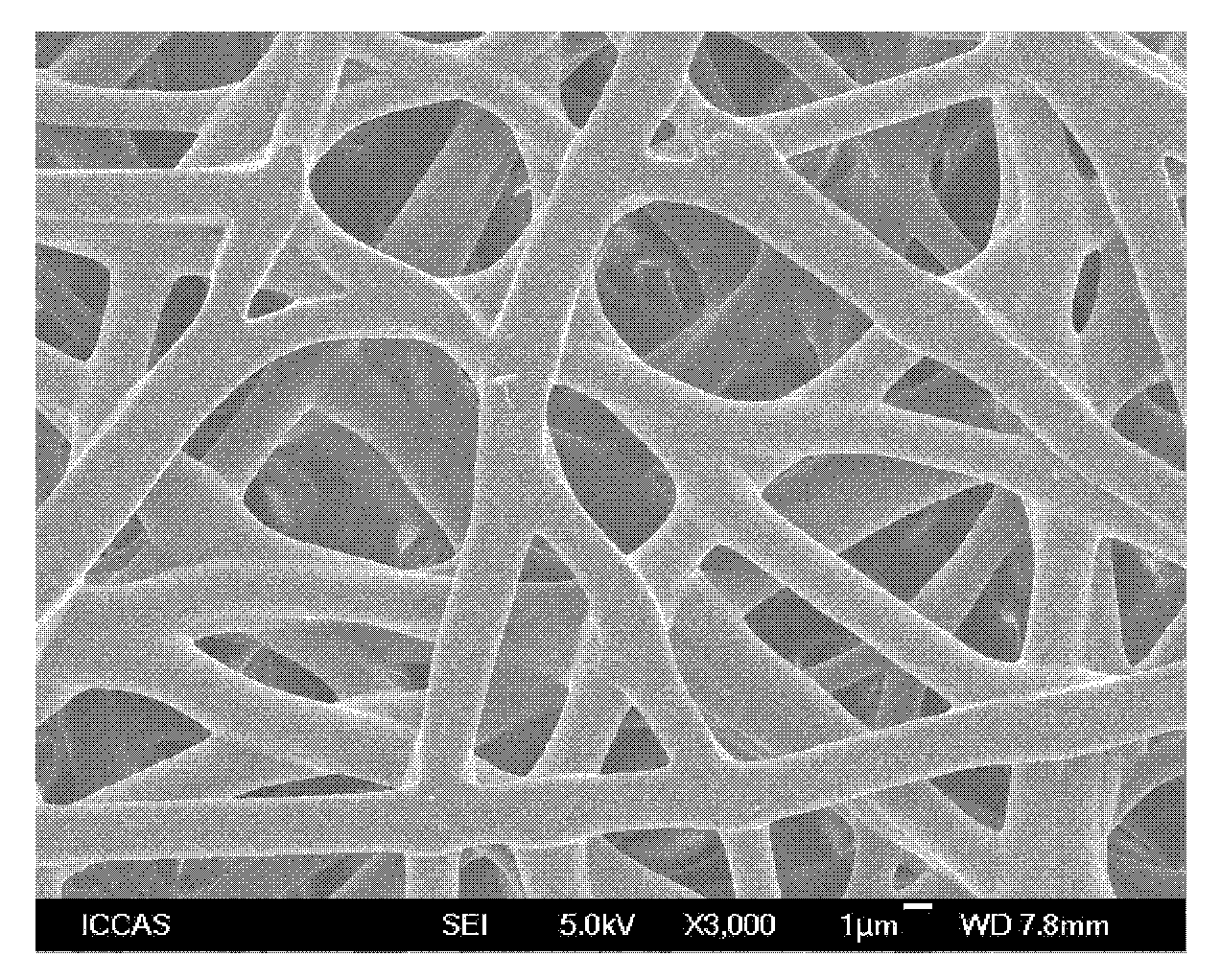

[0040] (2) Electrospinning: the PLGA solution obtained in step (1) is placed in the feeding syringe of the electrospinning equipment. Adjust the distance between the spinneret and the roller to 12cm, the ambient temperature for spinning is 25°C, and the air velocity in the environment is controlled at 0.5-0.8m 3 / hr, turn on the high-voltage power supply and the feeding syringe pump, adjust the voltage to 20kV, and the feeding speed of the solution is 20 μl / min, and perform spinning. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com