Liquid nitrogen washing purified synthetic gas and device for cryogenically separating and recovering LNG (liquefied natural gas) thereof

A cryogenic separation and synthesis gas technology, which is applied in liquefaction, refrigeration, liquefaction, solidification, etc., can solve the problems of unguaranteed calorific value and large component changes, etc. It is convenient to achieve large-scale progress, improve separation effect, and increase exchange rate. Effect of Heater Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

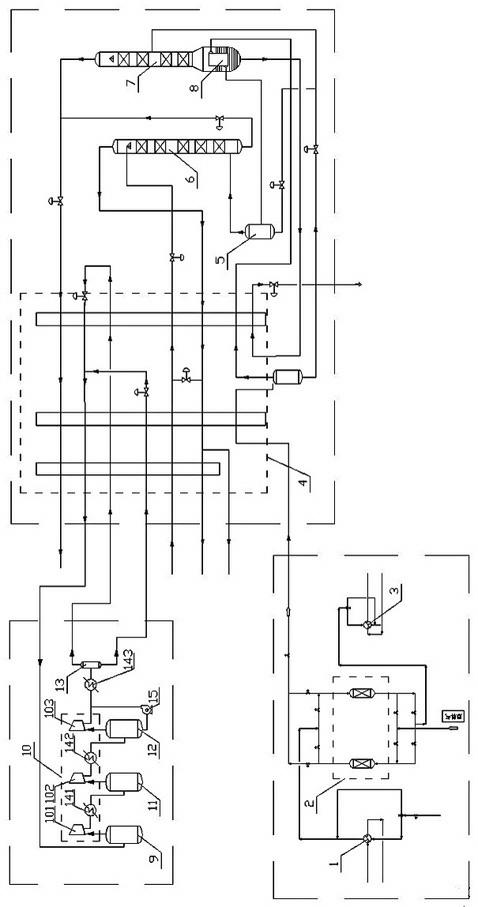

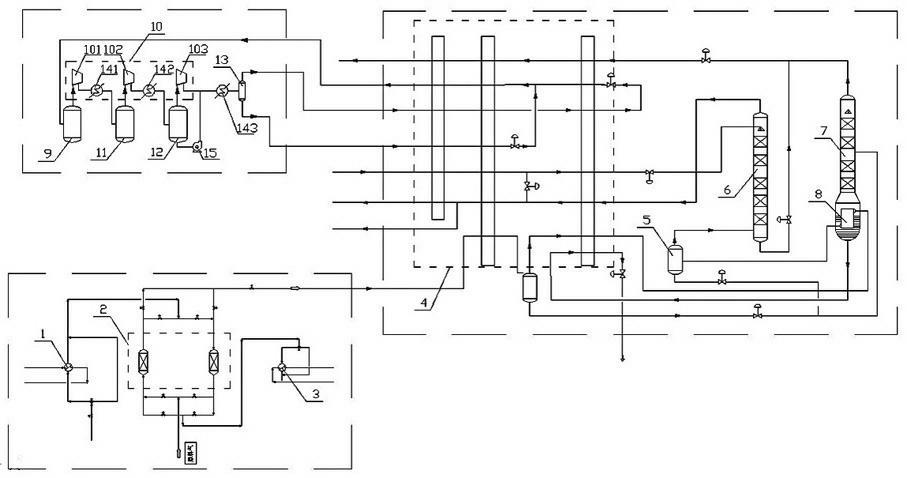

[0016] Liquid nitrogen washing and purification of synthesis gas and its cryogenic separation and recovery of LNG devices, such as figure 1 As shown, it includes raw gas pretreatment system, cryogenic purification and separation cold box, mixed refrigerant refrigeration cycle system, raw gas pretreatment system includes regeneration gas heater 1, molecular sieve adsorber 2, regeneration gas cooler 3, regeneration gas heating Device 1, molecular sieve adsorber 2 and regeneration gas cooler 3 are connected successively through pipelines, and the cryogenic purification separation cold box includes main heat exchanger 4, separation tank 5, nitrogen washing tower 6, methane rectification tower 7 and is arranged on The thermosiphon evaporator 8 in the methane rectification tower 7, the main heat exchanger 4, the separation tank 5, the nitrogen washing tower 6, and the methane rectification tower 7 are connected by pipelines successively, and the top of the methane rectification tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com