Lithium ion battery

A technology for lithium ion batteries and battery shells, applied in lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of easy degradation, poor adhesion, poor battery capacity and cycle performance, etc., to improve flexibility, reduce Effects of internal resistance, good adhesion and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

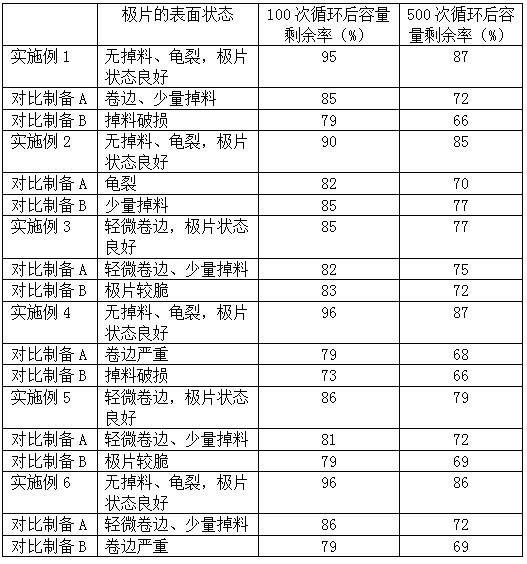

Examples

Embodiment 1

[0042] Composite water-soluble binder solution: the methylene oxide ethylene copolymer of 40% by weight (—(CH 2 (OCH 2 CH 2 ) m ) n —) and 60% by weight of polyvinyl nitrile (PAN) are uniformly mixed and then dissolved in deionized water to form a composite water-soluble binder solution. Its mass ratio is methylene oxide ethylene copolymer: polyvinyl nitrile: deionized water = 4:6:30.

[0043] Positive electrode composition: first make the thickener CMC into a 4% by weight aqueous solution, stir and mix with the conductive agent Super-P and flake graphite KS-6 for 1.5 hours, and then add nano-LiFePO 4 Mix well (D50=120nm), stir for 3 hours, then add 40% by weight of composite water-soluble binder solution, stir for 1 hour, and finally add 20% by weight of ethanol aqueous solution and stir for 30 minutes to obtain a water-based positive electrode, which is composed of LiFePO 4 : Conductive agent (Super-P / KS-6 / =3 / 1): CMC: Binder (Methylene oxide ethylene copolymer / polyvin...

Embodiment 2

[0060] Composite water-soluble binder solution: the methylene oxide ethylene copolymer of 10% by weight (—(CH 2 (OCH 2 CH 2 ) m ) n —) and 90% by weight of polyvinyl nitrile (PAN) are uniformly mixed and then dissolved in deionized water to form a composite water-soluble binder solution. Its mass ratio is methylene oxide ethylene copolymer: polyvinyl nitrile: deionized water = 1:9:30.

[0061] Positive electrode composition: first make the thickener CMC into a 4% by weight aqueous solution, stir and mix with the conductive agent Super-P and flake graphite KS-6 for 1.5 hours, and then add nano-LiFePO 4 Mix well (D50=120nm), stir for 3 hours, then add 40% by weight of composite water-soluble binder solution, stir for 1 hour, and finally add 20% by weight of ethanol aqueous solution and stir for 30 minutes to obtain a water-based positive electrode, which is composed of LiFePO 4 : Conductive agent (Super-P / KS-6 / =3 / 1): CMC: Binder (Methylene oxide ethylene copolymer / polyvin...

Embodiment 3

[0078] Composite water-soluble binder solution: the dimethylsiloxane-ethylene oxide copolymer of 10% by weight (—((CH 3 ) 2 (SiOOCH 2 CH 2 ) m ) n —) and 90% by weight of polyvinyl nitrile (PAN) are uniformly mixed and then dissolved in deionized water to form a composite water-soluble binder solution. Its mass ratio is dimethylsiloxane-ethylene oxide copolymer: polyvinyl nitrile: deionized water = 1:9:30.

[0079] Positive electrode composition: first make the thickener CMC into a 4% by weight aqueous solution, stir and mix with the conductive agent Super-P and flake graphite KS-6 for 1.5 hours, and then add nano-LiFePO 4 Mix well (D50=120nm), stir for 3 hours, then add 40% by weight of composite water-soluble binder solution, stir for 1 hour, and finally add 20% by weight of ethanol aqueous solution and stir for 30 minutes to obtain a water-based positive electrode, which is composed of LiFePO 4 : Conductive agent (Super-P / KS-6 / =3 / 1): CMC: Binder (Dimethicone-ethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com