Method for cleaning through hole smears of rigid-flexible printed circuit board

A printed circuit board, rigid-flex technology, applied in the secondary processing of printed circuits, cleaning/polishing of conductive patterns, chemical instruments and methods, etc. and other problems, to achieve the effect of good bite force, simple method and high decontamination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

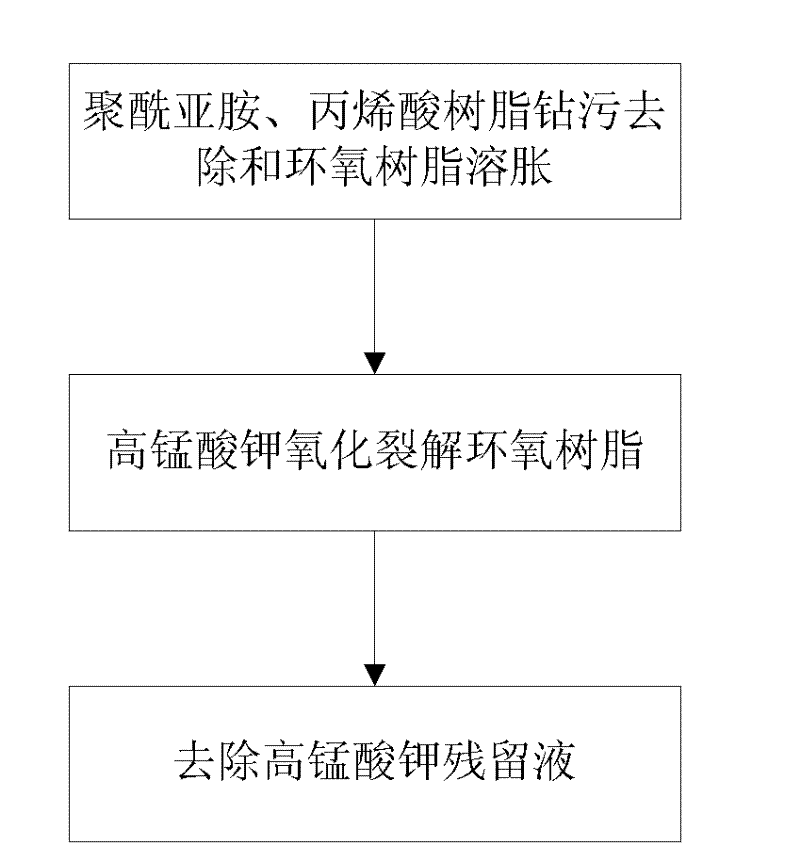

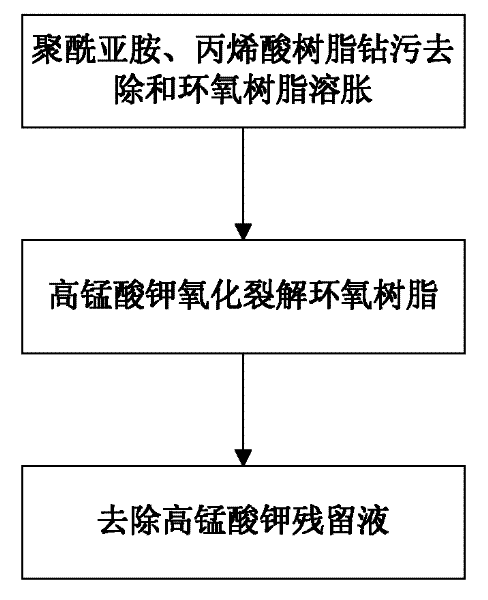

Method used

Image

Examples

Embodiment 1

[0025] Use a mechanical numerical control machine to drill 0.25mm through holes in the four-layer rigid-flex printed circuit board. The structure of the rigid-flex board is a double-sided flexible board in the middle, and a single-sided rigid board on both sides. The rigid board is Shengyi 18 / 0.2FR-4 single-sided copper-clad laminate, and the flexible board is Taihong 18 / 25 / 18 calendered PI halogen-free double-sided copper-clad laminate. Use the method of the present invention to remove drilling dirt, then hole metallization, its technological process is as follows:

[0026] Step 1: Prepare two kinds of decontamination solutions;

[0027] Among them, the first decontamination solution contains 35g of sodium hydroxide or potassium hydroxide per liter, 30g of ethylene glycol ethyl ether used as an epoxy resin swelling agent, 2g of butanediol as a solubilizer, and 2g of butanediol as a polyimide swelling agent. 40ml of hydrazine, the rest is water; the second decontamination sol...

Embodiment 2

[0036] Use a mechanical numerical control machine to drill 0.30mm through holes in the six-layer rigid-flex printed circuit board. The structure of the rigid-flex board is a double-sided flexible board in the middle and double-sided rigid boards on both sides. The rigid board is Shengyi 35 / 0.5 / 35FR-4 double-sided copper-clad laminate, and the flexible board is Taihong 18 / 25 / 18 calendered PI halogen-free double-sided copper-clad laminate. Use the inventive method to remove drilling dirt, hole metallization, its technological process is as follows:

[0037] Step 1: Prepare two kinds of decontamination solutions;

[0038] Among them, the first decontamination solution contains 35g of sodium hydroxide or potassium hydroxide per liter, 20g of ethylene glycol ethyl ether used as an epoxy resin swelling agent, 2g of butanediol as a solubilizer, and 2g of butanediol as a polyimide swelling agent. 40ml of hydrazine, the rest is water; the second decontamination liquid contains 35g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com