Haloalkane activated molecular sieve with low boiling point and refining process thereof

A technology of activating molecules and low boiling point, which is applied in organic chemistry, preparation of halogenated hydrocarbons, and other chemical processes, can solve the problems of high power consumption, difficult heat transfer, loss of adsorption capacity, etc. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

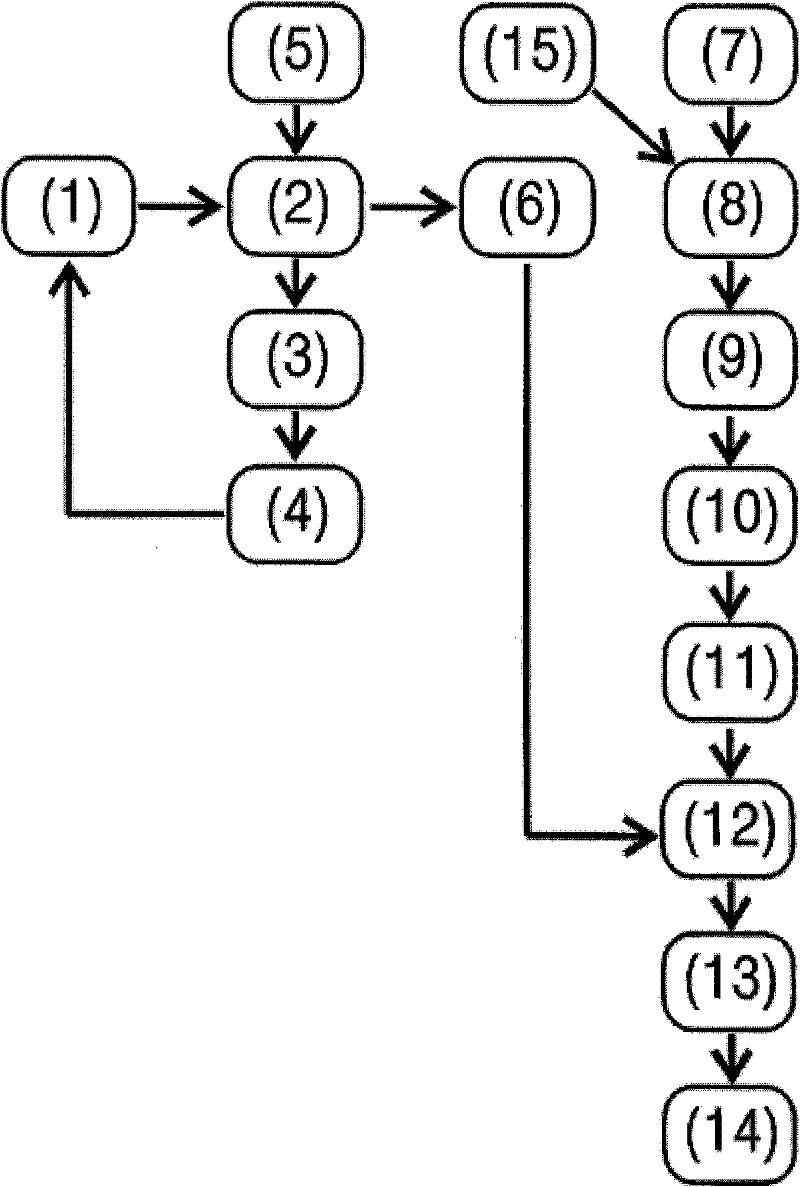

Image

Examples

Embodiment 1

[0014] The industrial grade chloromethane is decompressed and vaporized from the steel cylinder (7), and the pressure is controlled to be 0.12MPa. After washing with 6% sodium hydroxide solution in (9), it is cooled and removed in the cooler (10) at -16°C. After drying with activated carbon in (11), adsorb and remove impurities with 5A molecular sieve activated with methyl chloride in (12), condense into a liquid state through a -41°C total condenser (13), and put it into a finished steel cylinder.

[0015] The indicators before and after purification are as follows:

[0016] Purity%

Acid value ppm

Moisture ppm

non-volatile ppm

Before purification

97.50

13.6

130

80

After purification

99.93

0.5

40

33

[0017] Embodiment work 2:

[0018] Industrial-grade ethyl chloride is pressed into the gasifier (8) that has been put into the gasifier (8) such as adsorbent-AP of 2% ethyl chloride treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com