Catching and refining device of carbon dioxide gas

A gas capture and carbon dioxide technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of high product quality, no power consumption, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

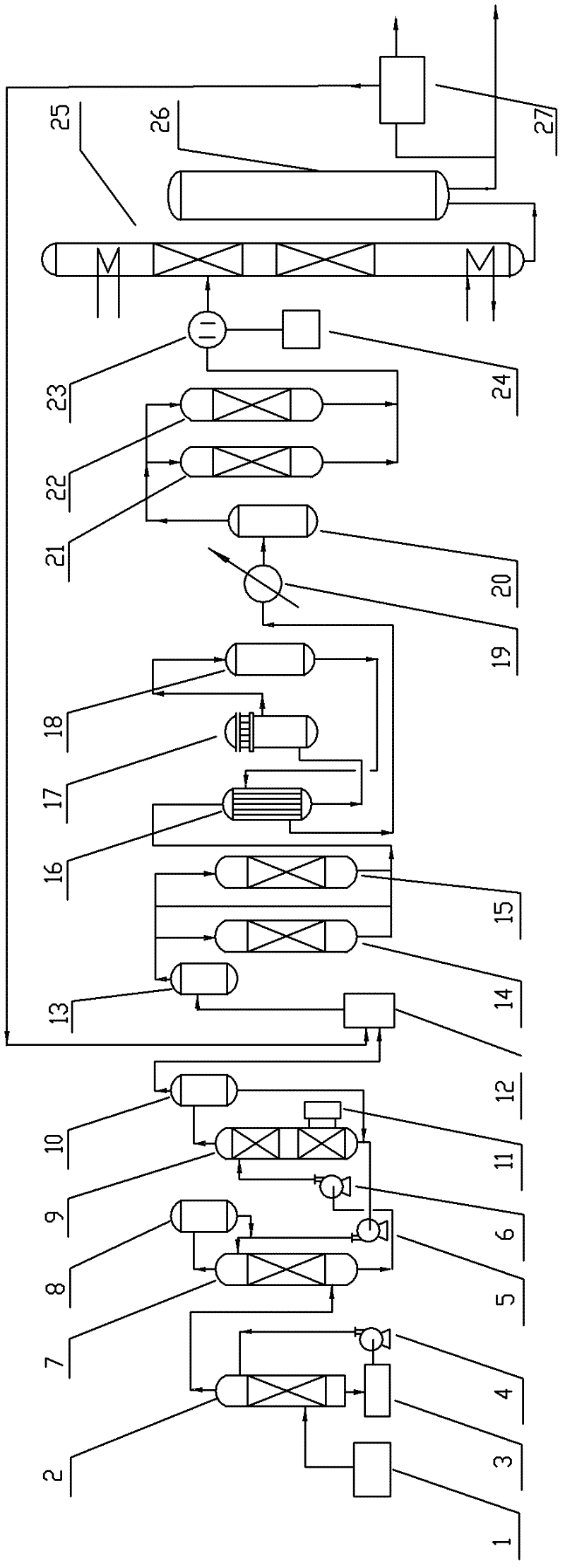

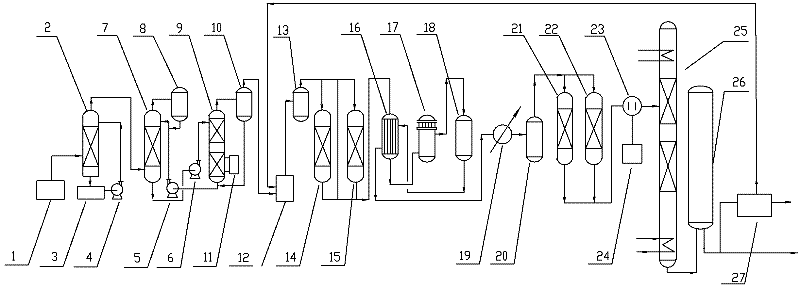

[0018]Specific embodiments of the present invention are shown in the accompanying drawings, the carbon dioxide gas capture and refining device is composed of a blower 1, a compressor 12, an enrichment system, a desulfurization system, a dehydrocarbon system, a purification system, a refrigeration system, a rectification system and a product system. composition. The front end of the enrichment system is connected to the blower 1, the rear end of the enrichment system is connected to the desulfurization system, the rear end of the desulfurization system is connected to the dehydrogenation system, the rear end of the dehydrogenation system is connected to the purification system, the rear end of the purification system is connected to the refrigeration system, and the back end of the refrigeration system is connected to the refrigeration system. The end is connected to the rectification system, and the rear end of the rectification system is connected to the product system. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com