Titanium dioxide with high-energy surface hollow structure and its preparation method

A hollow structure, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., to achieve the effect of novel structure, easy recycling, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

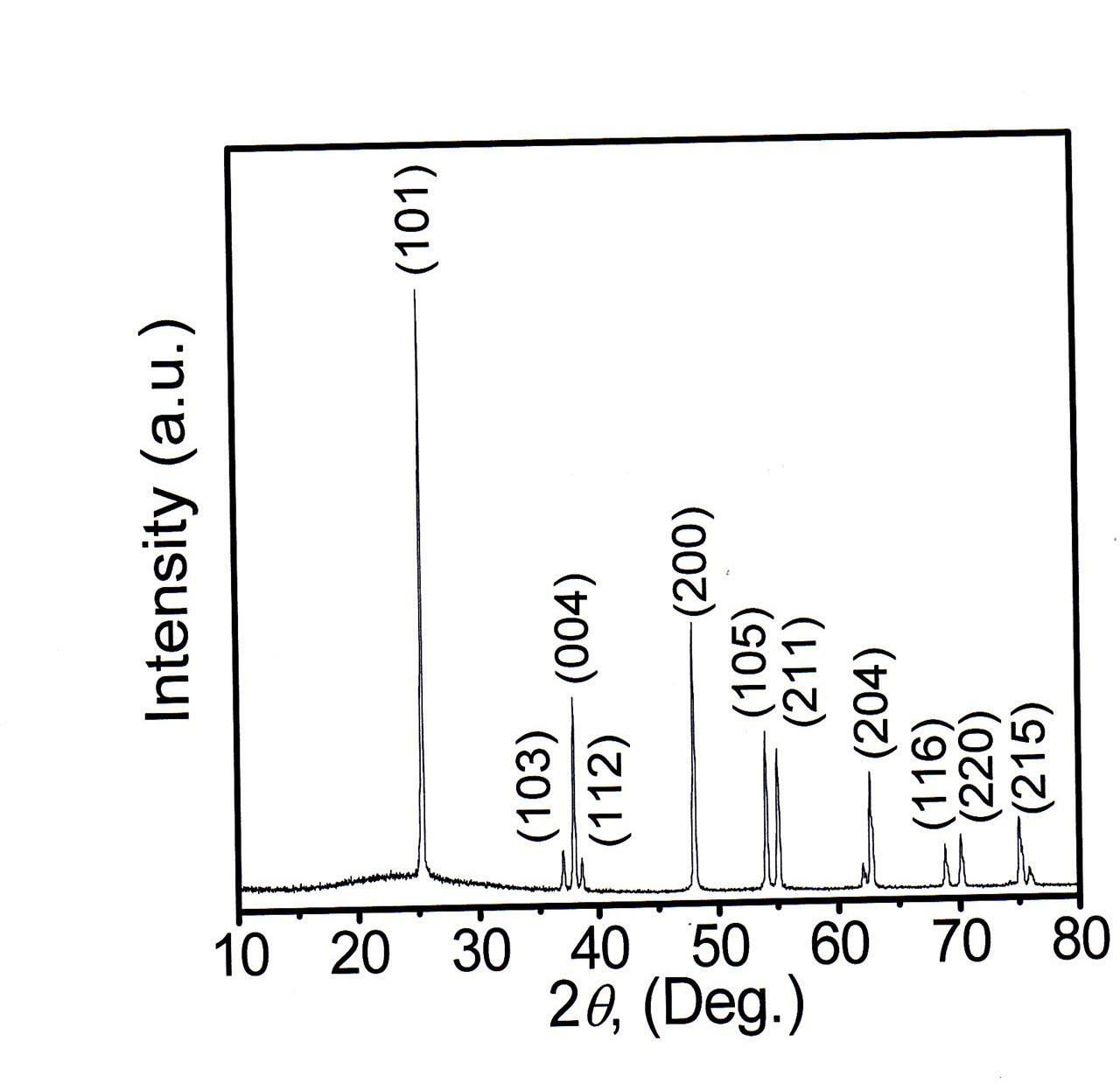

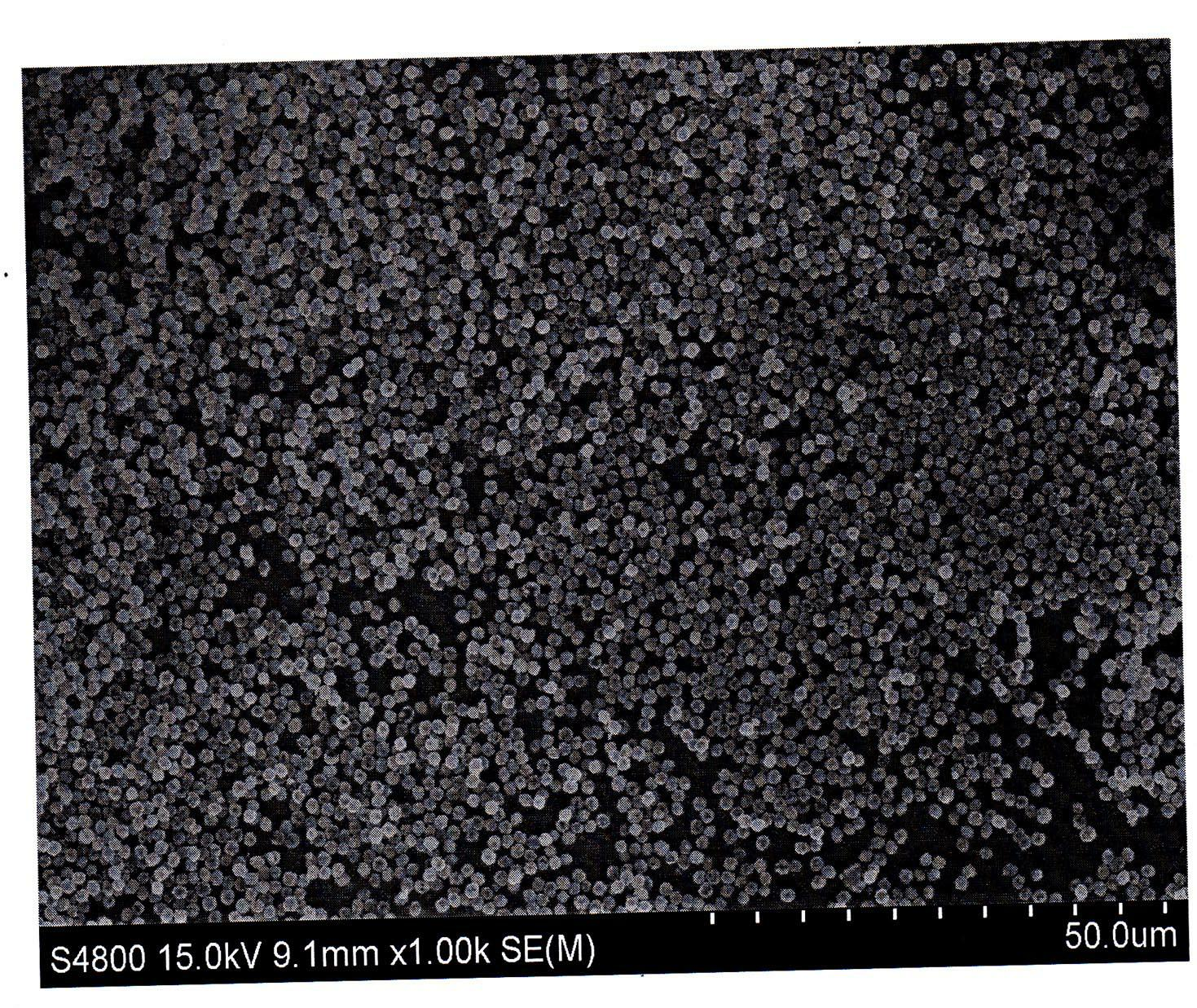

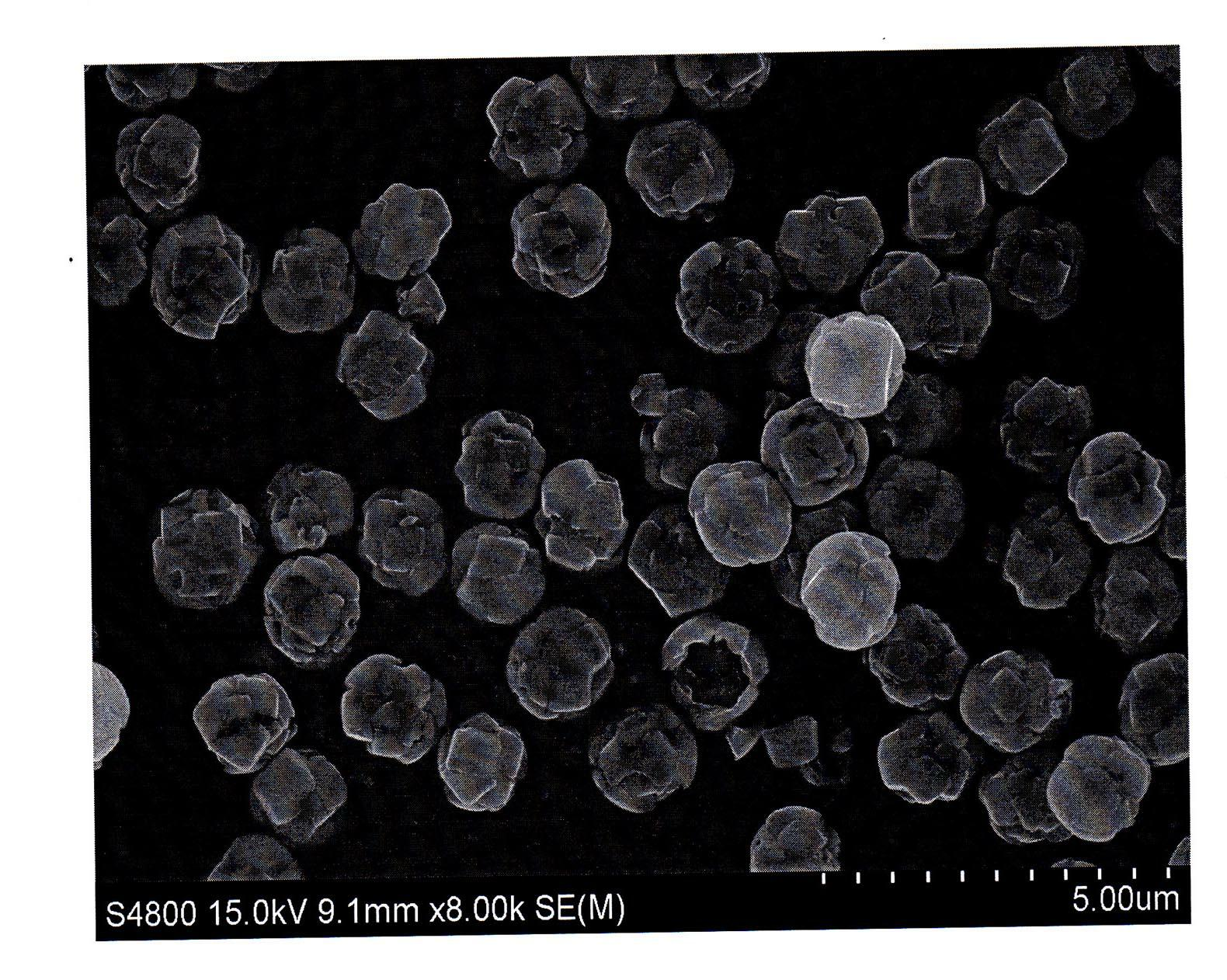

[0026] Take 0.1 ml of hydrofluoric acid with a concentration of about 47%, mix it with 3 ml of hydrogen peroxide solution with a concentration of about 30%; add 0.02 g of metal titanium powder to the solution obtained above, and stir for 5 minutes; deionize 27 ml Water was added to the above-mentioned stirred mixed solution, put into a polytetrafluoroethylene-lined hydrothermal reaction kettle, reacted at 160° C. for 4 hours, washed with deionized water and dried. The obtained titanium dioxide structure is anatase, the particle size is uniform, the average size is 1.5 microns, it is composed of agglomerated flake particles with high-energy surfaces, and it is a hollow structure, such as figure 1 , 2 , 3, 4 shown.

Embodiment 2

[0028] Take 0.2 ml of hydrofluoric acid with a concentration of about 47%, mix it with 6 ml of hydrogen peroxide solution with a concentration of about 30%; add 0.04 g of metal titanium powder to the solution obtained above, and stir for 5 minutes; deionize 57 ml Water was added to the above-mentioned stirred mixed solution, put into a polytetrafluoroethylene-lined hydrothermal reaction kettle, reacted at 170° C. for 15 hours, washed with deionized water and dried. The obtained titanium dioxide particles have an average size of 1 micron, are composed of agglomerated flake particles with high-energy surfaces, and have a hollow structure.

Embodiment 3

[0030] Take 0.5 ml of hydrofluoric acid with a concentration of about 47%, mix it with 15 ml of hydrogen peroxide solution with a concentration of about 30%; add 0.10 g of metal titanium powder to the solution obtained above, and stir for 5 minutes; deionize 135 ml Water was added to the above-mentioned stirred mixed solution, put into a polytetrafluoroethylene-lined hydrothermal reaction kettle, reacted at 180° C. for 20 hours, washed with deionized water and dried. The obtained titanium dioxide particles have an average size of 2 microns, are composed of agglomerated flake particles with high-energy surfaces, and have a hollow structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com