Non-yellowing polyurethane slurry for hasp, and preparation method thereof

A polyurethane slurry, polyester polyol technology, applied in the direction of polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve the problem of non-yellowing special polyurethane slurry, etc. The effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

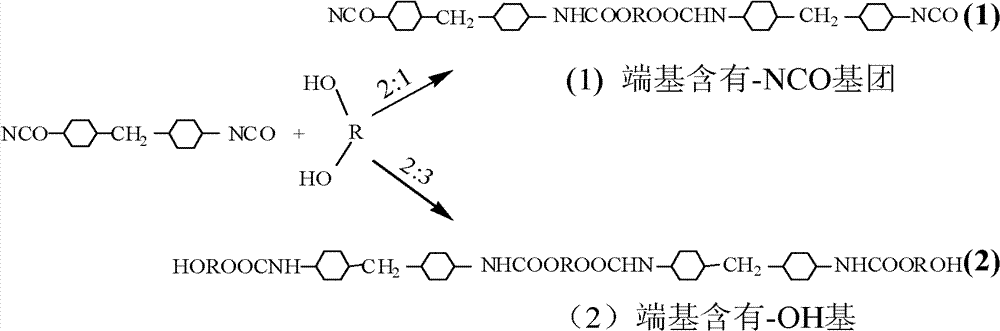

Method used

Image

Examples

Embodiment 1

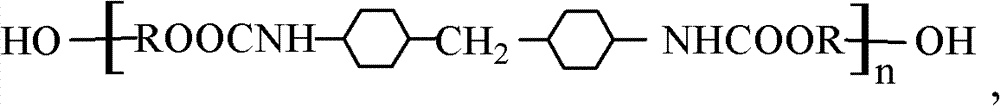

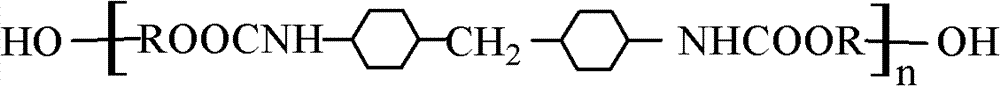

[0029] A non-yellowing buckle polyurethane slurry, the general molecular formula of the polyurethane slurry is:

[0030]

[0031] In the formula, R is a hydrocarbon group without an aromatic nucleus, which refers to a hydrocarbon group of a polyester polyol and a chain extender (low-carbon diol).

[0032] The specific preparation method is as follows:

[0033] Put the primer solvent composed of 158g of petroleum grade toluene and 79g of N-N dimethylformamide (DMF) into the reactor, then put the molecular weight of 1500 ± 150 polyester polyol 255.7g, polyester grade ethylene glycol 32.6g, 0.89g of trimethylolpropane was put in at one time, stirred evenly, then sealed, heated to 60°C, slowly added 186.4g of H12MDI dropwise, the temperature was controlled at 85°C, dripped in about 3 hours, then heated to 90°C, and kept for 1 hour, add the catalyst, and then react for 90 minutes to measure the viscosity to reach the specified index, and stop the reaction.

[0034] Cool down, ...

Embodiment 2

[0036] A non-yellowing buckle polyurethane slurry, the general molecular formula of the polyurethane slurry is:

[0037]

[0038] In the formula, R is a hydrocarbon group without an aromatic nucleus, which refers to a hydrocarbon group of a polyester polyol and a chain extender (low-carbon diol).

[0039] The specific preparation method is as follows:

[0040] Put the primer solvent composed of 160g of petroleum grade toluene and 81g of N-N dimethylformamide (DMF) into the reactor, then put the molecular weight of 2000 ± 200 polyester polyol 298.3g, polyester grade ethylene glycol 27.1g, Add 0.74g of trimethylolpropane at one time, stir evenly, then seal, heat up to 65°C, slowly add 155.3g of hydrogenated phenylmethane diisocyanate dropwise, control the temperature at 90°C, drop it in about 3 hours, and then heat up to 90°C ℃, keep warm for 1 hour, add the catalyst, and react for another 40 minutes to measure the viscosity to reach the specified index, and stop the reactio...

Embodiment 3

[0043] A non-yellowing buckle polyurethane slurry, the general molecular formula of the polyurethane slurry is:

[0044]

[0045] In the formula, R is a hydrocarbon group without an aromatic nucleus, which refers to a hydrocarbon group of a polyester polyol and a chain extender (low-carbon diol).

[0046] The specific preparation method is as follows:

[0047]Put the primer solvent composed of 160g of petroleum grade toluene and 80g of N-N dimethylformamide (DMF) into the reaction kettle, and then put 116.2g of polyester polyol with a molecular weight of 1500±150 and a polyester polyol with a molecular weight of 2000±200 162.7g of alcohol, 26.6g of polyester grade ethylene glycol, 4.2g of 1.4 butanediol, 0.8g of trimethylolpropane in one time, stir evenly, then seal, heat up to 62°C, slowly add 169.5g of H12MDI dropwise, the temperature Control the temperature at 87°C, drop it in about 3 hours, then raise the temperature to 90°C, keep it warm for 2 hours, add the catalyst,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com