Sintered material for valve guides and production methods therefor

A valve guide and raw material technology, applied in the field of sintered valve guide materials and its preparation, can solve the problems of harsh sliding environment, reduced lubricating oil supply, etc., and achieve the effect of maintaining wear resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

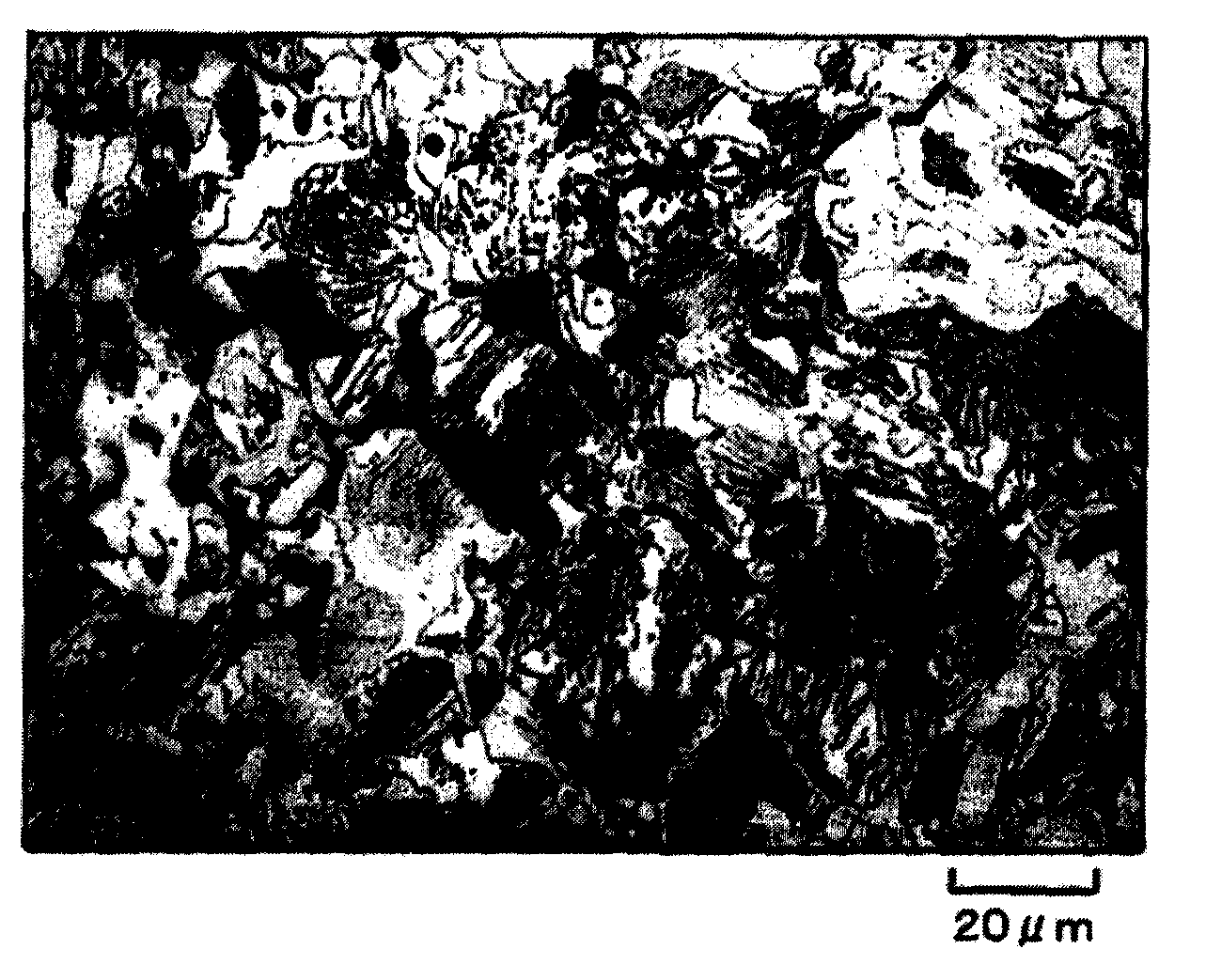

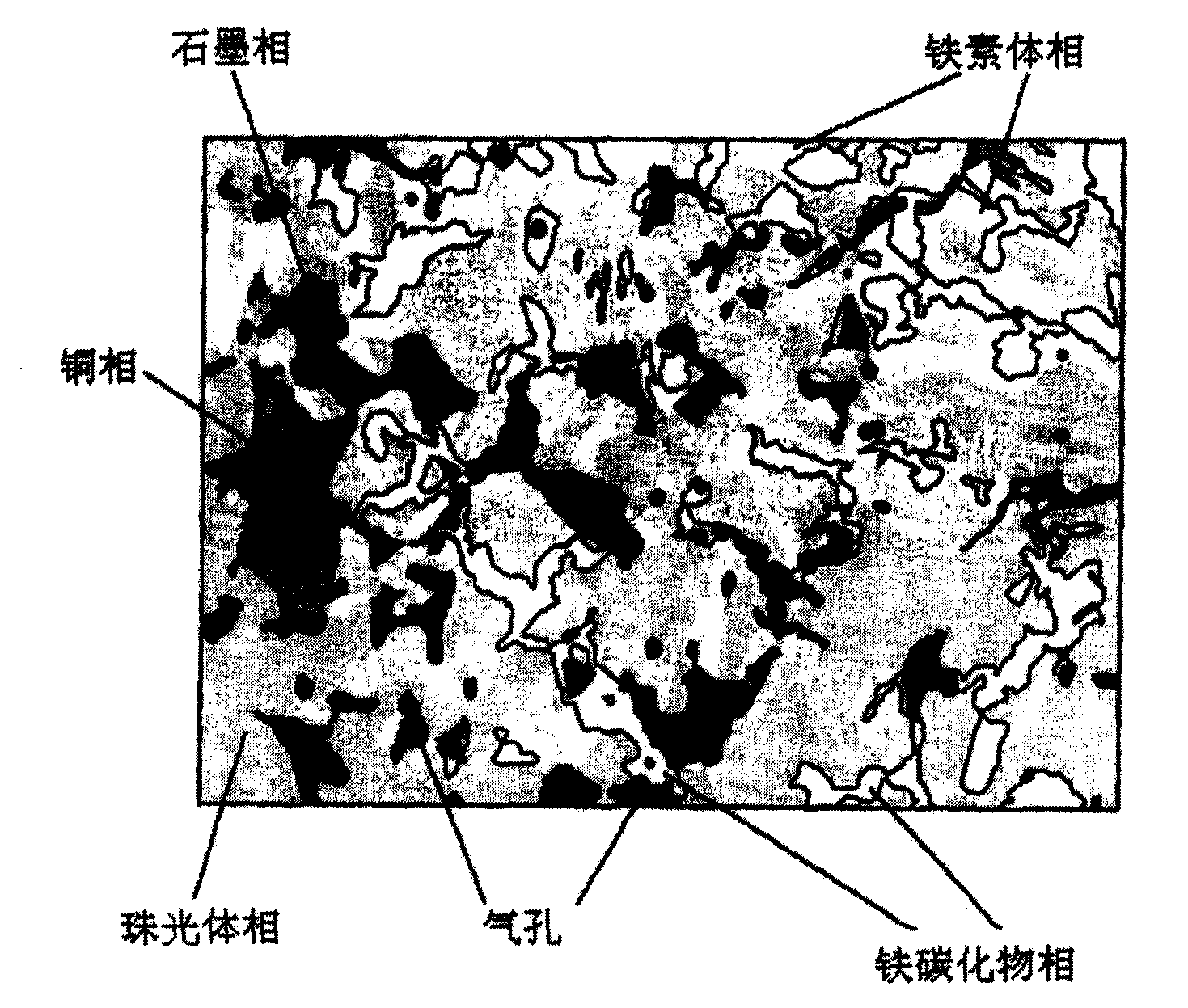

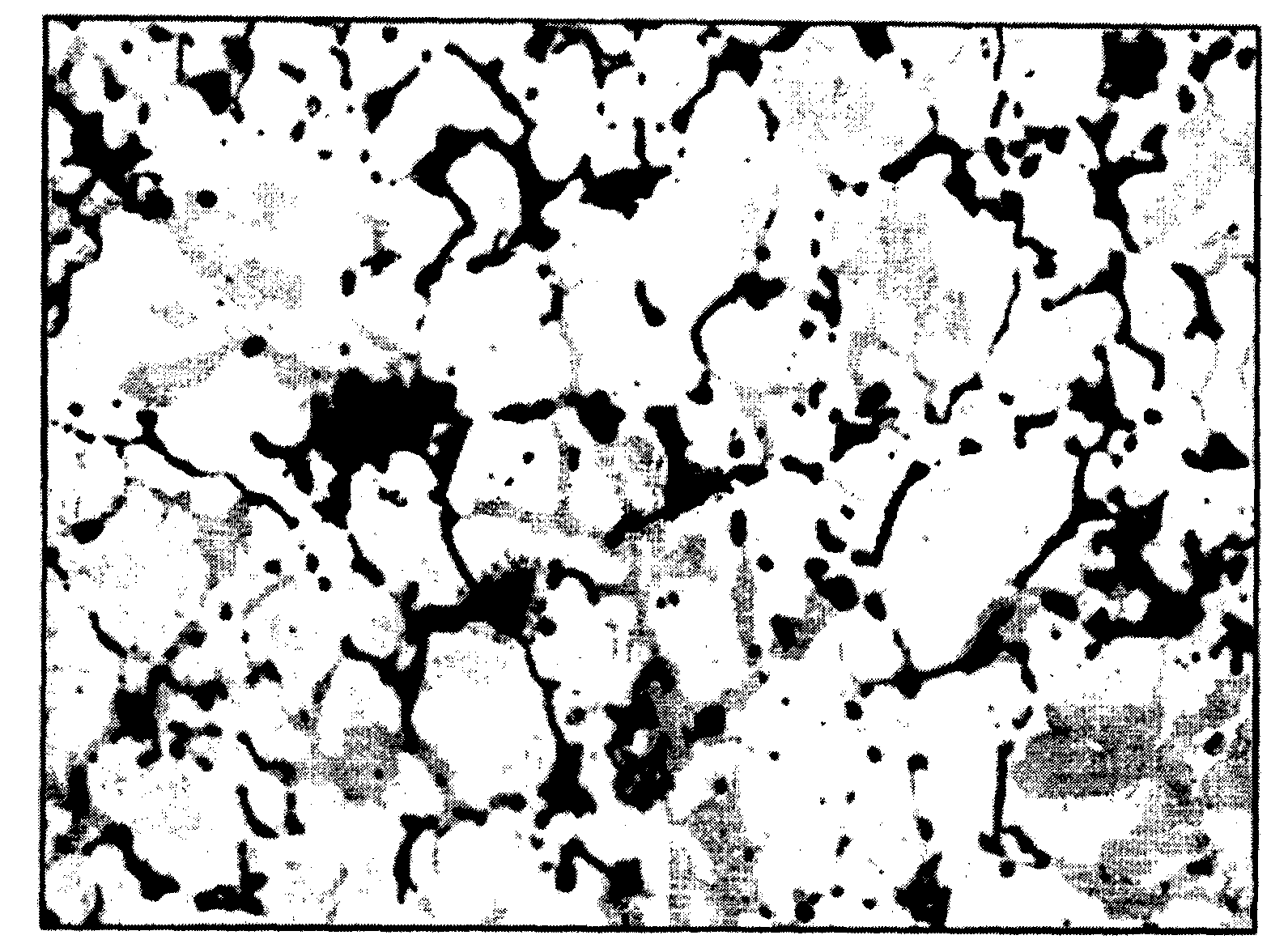

Image

Examples

preparation example Construction

[0040] [Method for producing the first sintered valve guide material]

[0041] In order to suppress the diffusion of Cu in the above-mentioned iron matrix, a matrix with uneven Cu concentration is formed where the part with high Cu concentration and the part with low Cu concentration coexist, and the dispersed plate-shaped iron carbide (Fe 3 In the case of the sintered valve guide material of C), the first method of producing the sintered valve guide material of the present invention is characterized in that, as the raw material powder, when a mixed powder obtained by adding copper powder and graphite powder to iron powder is used, The heating temperature during sintering (sintering temperature) is set to be lower than the melting point of Cu (1085° C.), and sintering is performed using only Cu diffusion into the iron matrix as solid phase diffusion without generating a Cu liquid phase.

[0042] At this time, if the raw material powder is provided with graphite powder in which...

no. 1 Embodiment

[0061] Prepare iron powder, copper powder and graphite powder, add copper powder and the graphite powder of 2% mass as shown in table 1 in iron powder, mix and prepare raw material powder, the raw material powder that will make is added under the molding pressure of 650MPa Compression, forming a circular tubular green compact with an outer diameter of 11mm, an inner diameter of 6mm, and a length of 40mm (for wear tests) and a round tubular green compact with an outer diameter of 18mm, inner diameter of 10mm, and a length of 10mm (for radial compressive strength tests) , sintering the obtained circular tubular green compact in an ammonia decomposition atmosphere at a heating temperature of 1000°C, setting the holding time at 30 minutes, and then cooling to prepare sintered test samples of test samples 01-10 . In addition, when cooling from heating temperature to normal temperature, the cooling rate in the temperature range from 850 degreeC to 600 degreeC was 10 degreeC / min.

...

no. 2 Embodiment

[0077] Using the iron powder, copper powder and graphite powder used in the first embodiment, add 2% mass of copper powder, graphite powder in the ratio shown in Table 2 to the iron powder, mix and prepare the raw material powder, and prepare the raw material The powder was shaped and sintered under the same conditions as in the first embodiment to prepare test samples with test sample numbers 12-17. The overall composition of these test products is shown in Table 2 together. In addition, with respect to these test samples, an abrasion test and a radial compression test were performed in the same manner as in the first example, and the area ratio of the iron carbide phase and the area ratio of the copper phase were measured. The results are shown in Table 2 together. It should be noted that, as an example in which the graphite powder addition amount is 2% by mass, the values of the test sample whose test sample number is 05 in the first embodiment are shown in Table 2 toget...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com