Method for preventing metal target from breakdown during physical vapor deposition sputtering process

A technology of physical vapor deposition and sputtering process, which is applied in the field of semiconductor manufacturing to avoid unnecessary losses and prevent poor target quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

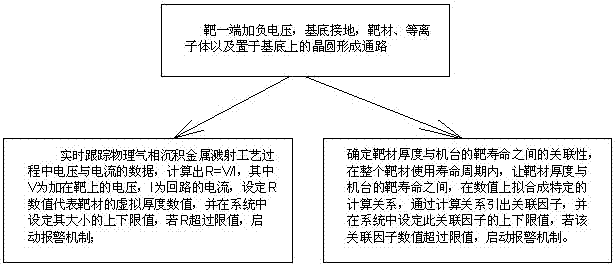

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in combination with principle diagrams and specific operation examples.

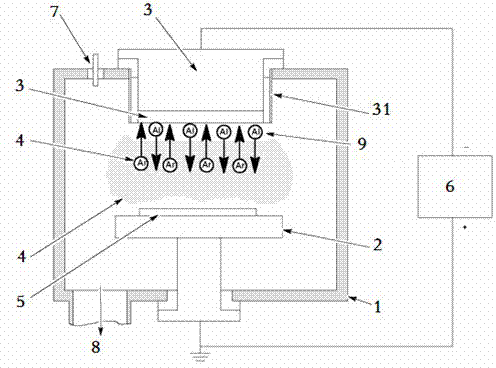

[0022] Such as figure 1 As shown, the method for preventing metal targets from being punctured during the physical vapor deposition sputtering process of the present invention is completed based on a sputter coating device. The sputter coating device includes a vacuum chamber 1, an anode 2 and an anode disposed in the vacuum chamber 1 Cathode target material 3, coating product and gas supply system, gas supply system comprises air inlet 7 and the gas supply channel that connects external gas source and air inlet 7, target 3, plasma 4 and crystal placed on substrate 5 The circle (not marked in the figure) forms a path with the power supply 6, negative voltage is applied to one end of the target 3, and the base 5 is grounded. In addition, the target 3 is provided with a ground shield 31, and the outlet 8 in the figure is connected to an external ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com