A Method of Realizing High Performance Copper Interconnection Using Upper Mask

A high-performance, copper interconnection technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of unfavorable etching process etching shape and size, reduce interconnection reliability, difficult to completely fill, etc. , to achieve the effect of reducing chip interconnection resistance, increasing process difficulty, and reducing interconnection resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

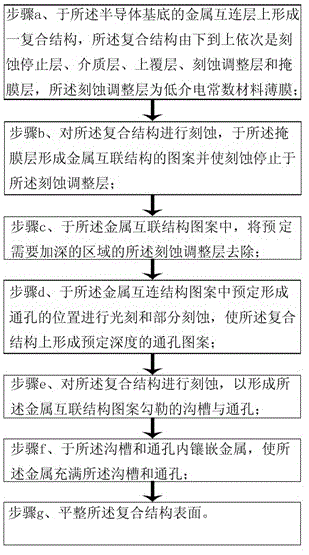

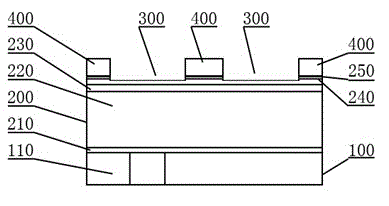

[0046] like figure 1 As shown, a method for realizing high-performance copper interconnection by using an upper mask in the present invention includes a semiconductor substrate 100 with a metal interconnection layer 110, and includes the following specific steps:

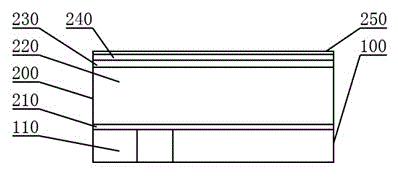

[0047] like figure 2 As shown, in step a, a composite structure 200 is formed on the metal interconnection layer 110 of the semiconductor substrate 100, and the composite structure 200 is an etching stop layer 210, a dielectric layer 220, an upper cladding layer 230, and an etching adjustment layer from bottom to top. layer 240 and mask layer 250.

[0048]Wherein the etching stop layer 210 is a nitrogen-doped silicon carbide layer, and its formation method can be chemical vapor deposition; the dielectric layer 220 can be fluorine-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com