Novel killing algicide

A biocidal and algicide, a novel technology, applied in biocides, biocides, herbicides and algicides, etc., can solve the problems of unstable chemicals, secondary pollution, toxicity, etc., to protect industrial equipment and prolong its use The effect of life and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

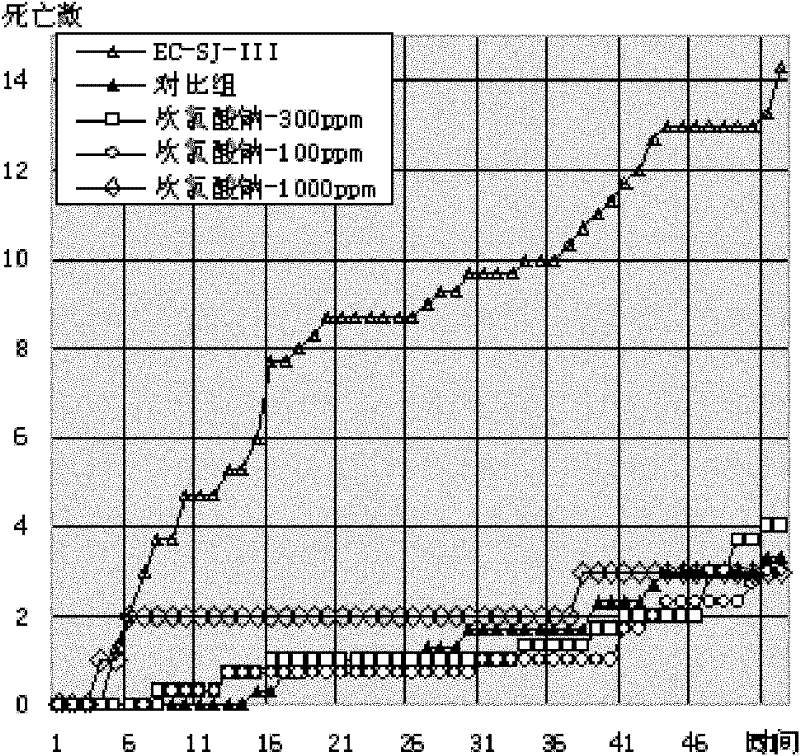

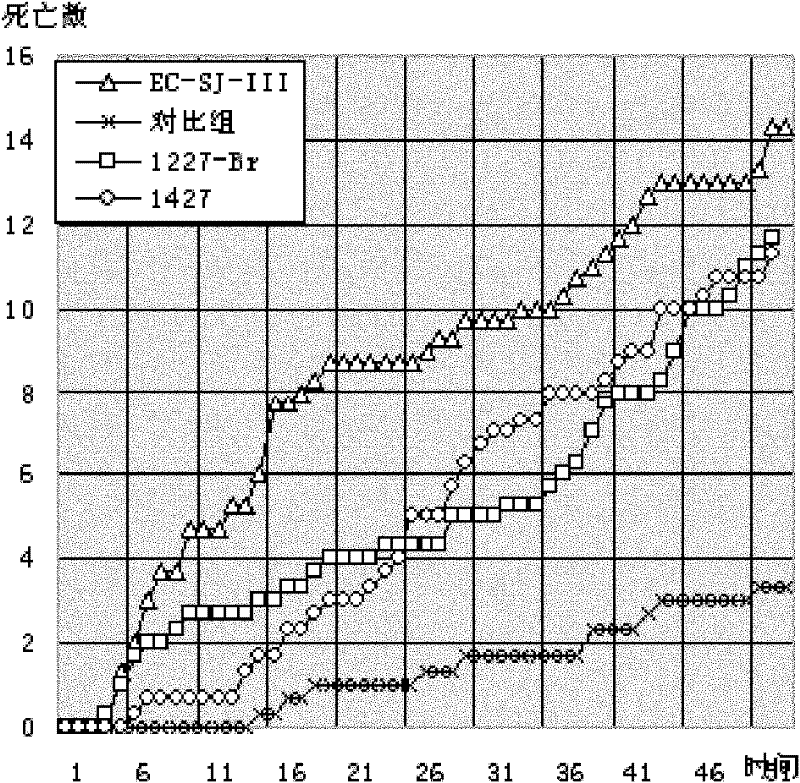

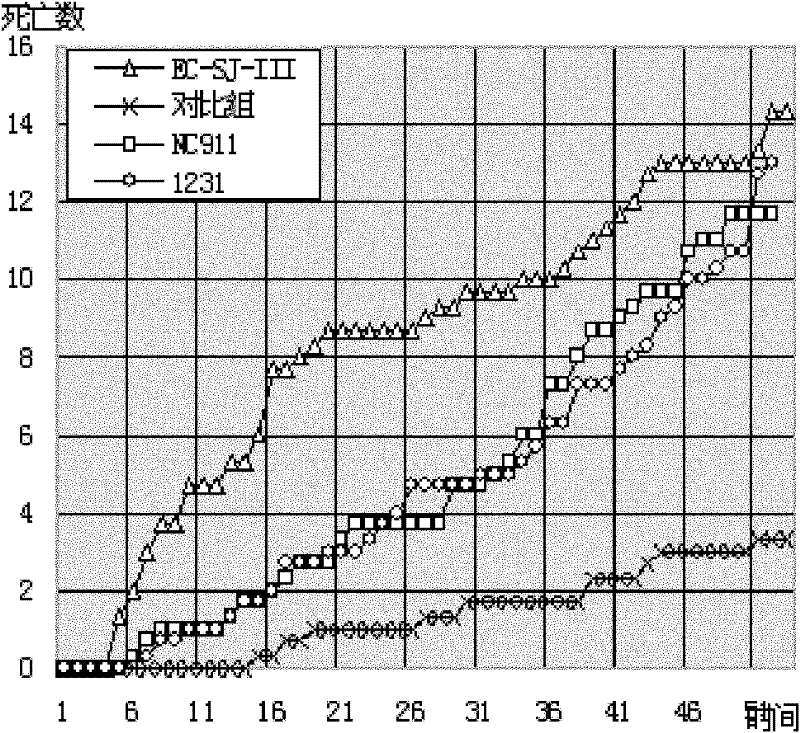

Image

Examples

Embodiment 1

[0090] Implementation 1. Get the following composition:

[0091] Alkylguanidine salt 1.5 kg,

[0092] Alkyldiethanolamide 12.5 kg,

[0093] Polyvinyl alcohol 1 kg,

[0094] Fatty amine 2 kg,

[0095] Fatty amine adduct 12 kg,

[0096] Quaternary ammonium complex 20 kg,

[0097] Limonene 6 kg,

[0098] Citral 4 kg,

[0099] Emulsifier 3 kg,

[0100] Alkali + silicone resin additive 3 kg,

[0101] 35 kg of deionized water.

[0102] Concrete implementation 1 processing operation steps are as follows:

[0103] (1) get bottom water deionized water 35kg, put into the stirred kettle that has jacket heating and cooling,

[0104] (2) stir and heat up to 50°C, add 3kg of emulsifier, stir for 5 minutes,

[0105] (3) Add 12kg of fatty amine adduct, stir, and keep warm at 50°C for 25 minutes,

[0106] (4) Add fatty amine 2kg, polyvinyl alcohol 1kg and limonene 6kg, stir then, at 50 ℃ of temperature, be incubated 60 minutes,

[0107] (5) Add 12.5kg of alkyldiethanolamide, stir,...

Embodiment 2

[0113] Take the following ingredients:

[0114] Alkylguanidine salt 1.5 kg,

[0115] Alkyldiethanolamide 12.5 kg,

[0116] Polyvinyl alcohol 1 kg,

[0117] Fatty amine 2 kg,

[0118] Fatty amine adduct 19 kg,

[0119] quaternary ammonium complex 29 kg,

[0120] Limonene 4 kg,

[0121] Citral 2 kg,

[0122] Emulsifier 2.5 kg,

[0123] Alkali + silicone resin additive 3 kg,

[0124] Deionized water 23.5 kg.

[0125] Concrete implementation 2 processing operation steps are the same as embodiment 1.

Embodiment 3

[0126] Implementation 3, get the following composition:

[0127] Alkylguanidine salt 1.5 kg,

[0128] Alkyl diethanolamide 10 kg,

[0129] Polyvinyl alcohol 1 kg,

[0130] Fatty amine 2 kg,

[0131] Fatty amine adduct 8 kg,

[0132] Quaternary ammonium complex 14 kg,

[0133] Limonene 6 kg,

[0134] Citral 4 kg,

[0135] Emulsifier 3 kg,

[0136] Alkali + silicone resin additive 2.5 kg,

[0137] 48 kg of deionized water.

[0138] The concrete implementation 3 processing operation steps are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com