Amphiphilic polymerizable monomer and amphiphilic tackifying copolymer, and preparation methods and application thereof

A copolymer and amphiphilic technology, which is applied in the fields of amphiphilic polymerizable monomers and amphiphilic viscosity-increasing copolymers and their preparation and application, can solve the problems of poor water solubility, prevent high-temperature hydrolysis, and reduce production costs , good heat resistance and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

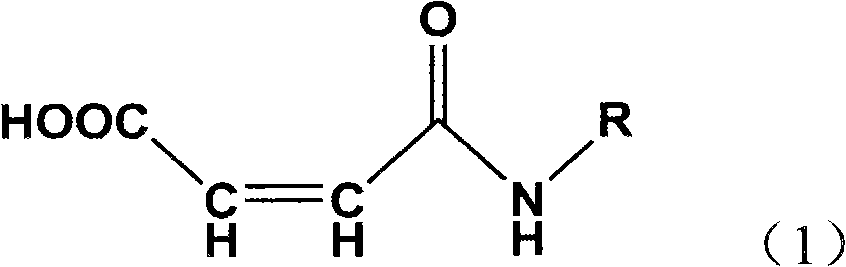

[0028] According to the preparation method of the amphiphilic polymerizable monomer of the present invention, the method comprises, under the amination reaction conditions of the acid anhydride, in an organic solvent, aliphatic amines with 6-18 carbon atoms or 6 carbon atoms -18 arylamine in contact with maleic anhydride.

[0029] In a preferred case, the molar ratio of the fatty amine or aromatic amine to maleic anhydride may be 0.8-10:1, preferably 1-5:1, more preferably 1-1.2:1, most preferably 1:1, when the amount of the aliphatic amine or aromatic amine and maleic anhydride is within the above range, it is beneficial to obtain the amphiphilic polymerizable monomer of the present invention.

[0030] In the preparation method of the amphiphilic polymerizable monomer of the present invention, the aliphatic amine having 6-18 carbon atoms can be n-hexylamine, n-octylamine, n-nonylamine, n-decylamine, n-dodecylamine and n-dodecylamine. Tetradecylamine, etc., the aromatic amine...

Embodiment 1

[0060] This example serves to illustrate the amphiphilic polymerizable monomers and amphiphilic adhesion-promoting copolymers of the present invention and methods for their preparation.

[0061] (1) Preparation of amphiphilic polymerizable monomers:

[0062] Add 1 mol of n-octylamine and 1 mol of maleic anhydride to 40 mol of diethyl ether, react at a reaction temperature of 10°C for 5 hours, filter, vacuum dry, and confirm by nuclear magnetic and infrared spectrum analysis to obtain amphiphilic Polymerized monomer n-octyl amido maleic acid (R in formula (1) is n-octyl).

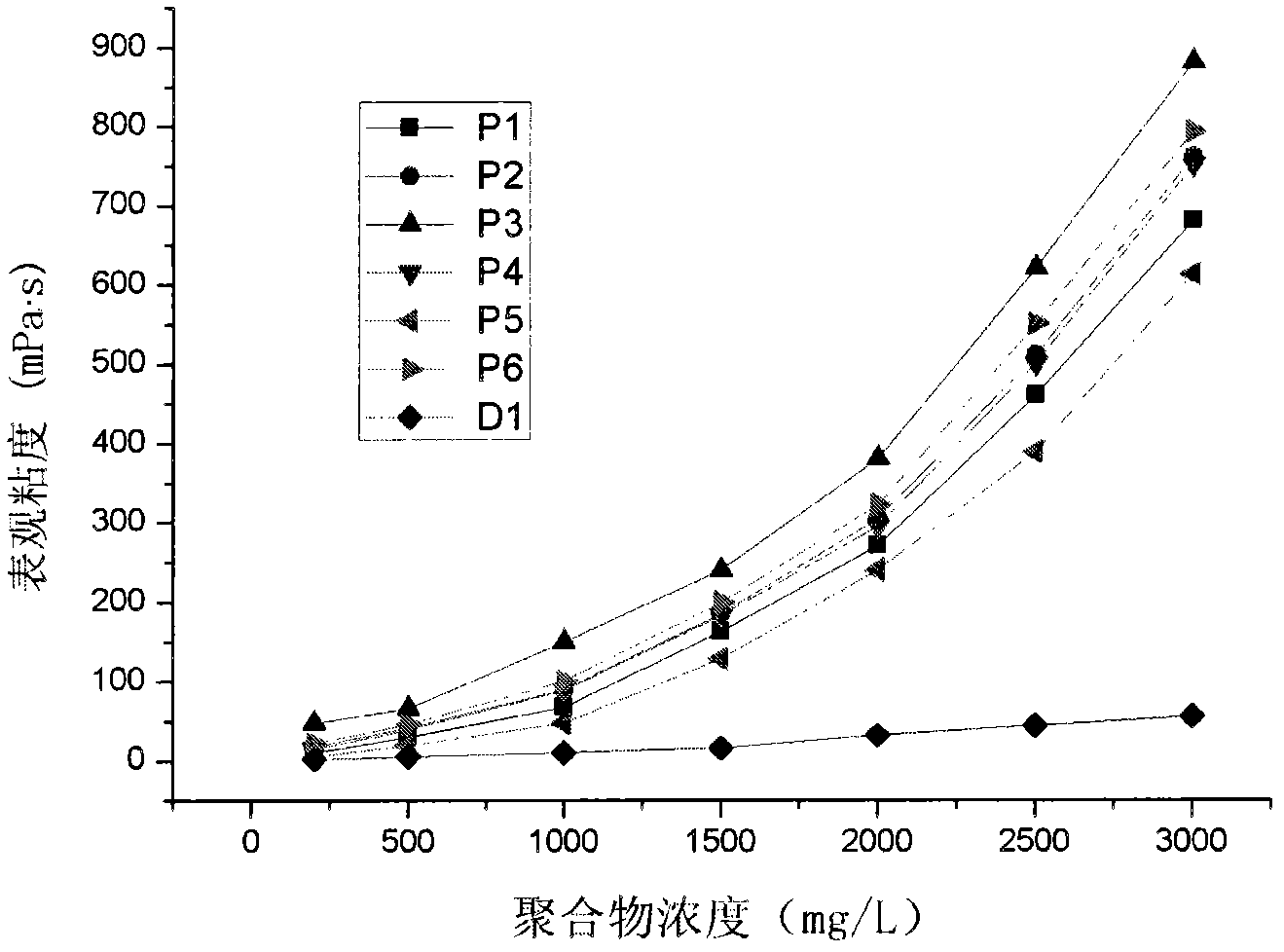

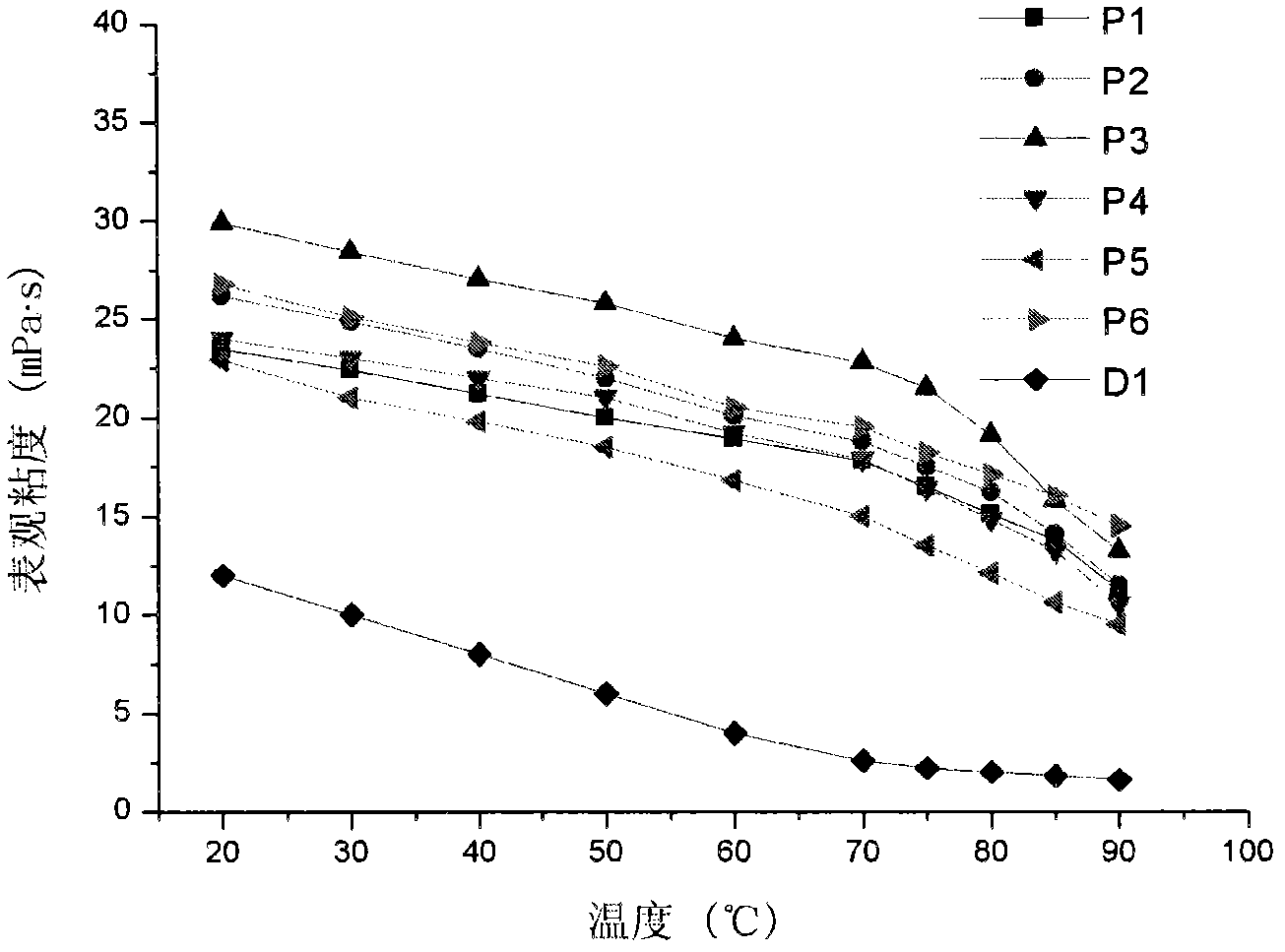

[0063] (2) Preparation of tackifying polymer P1:

[0064] Add 12.8g of acrylamide, 6.8g of acrylic acid and 2.0g of n-octylamidomaleic acid obtained above into the polymerization reactor, add 55ml of deionized water, adjust the pH to 8.2 with sodium carbonate, and then pass through high-purity Nitrogen bubbling deoxygenation, add composite initiator 2.2mg after half an hour, this composite initiator is mad...

Embodiment 2

[0068]This example serves to illustrate the amphiphilic polymerizable monomers and amphiphilic adhesion-promoting copolymers of the present invention and methods for their preparation.

[0069] (1) Preparation of amphiphilic polymerizable monomers:

[0070] Add 1 mol of dodecylamine and 1 mol of maleic anhydride to 36 mol of chloroform, react at a reaction temperature of 15°C for 6 hours, filter, vacuum dry, and confirm by nuclear magnetic and infrared spectrum analysis to obtain amphiphilic Polymerized monomer n-dodecyl amido maleic acid (R in formula (1) is n-dodecyl).

[0071] (2) Preparation of tackifying polymer P2:

[0072] Add 11.8 g of acrylamide, 8.0 g of 2-acrylamido-2-methylpropanesulfonic acid and 1.6 g of n-dodecyl amido maleic acid obtained above into the polymerization reactor, add 55 ml of deionized water, and use Ammonia water adjusts the pH to 7.8, then feeds high-purity nitrogen gas bubbles to remove oxygen, and adds 2.8 mg of a composite initiator after h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com