Green and energy-saving fluorescent powder/glass compound luminous material and preparation method thereof

A technology of luminescent material and fluorescent powder, applied in the field of green energy-saving fluorescent powder/glass composite luminescent material and its preparation, to achieve the effects of reducing pollution, high transparency, and promoting the development of new energy and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

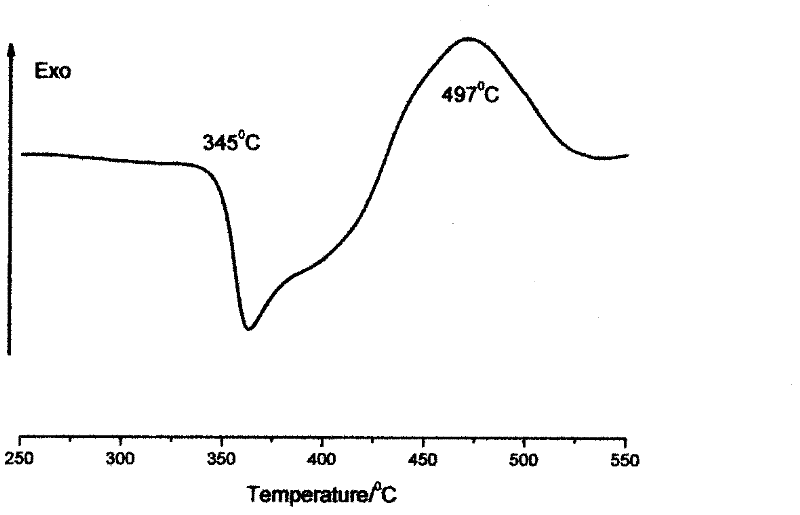

[0019] The glass matrix material is 29P 2 o 5 -42ZnO-9SO 3 -18Na 2 Phosphate glass of O-2SnO (mol%), the glass has the characteristics of low melting temperature and softening temperature, and the DSC curve is as follows figure 1 shown. After the glass is melted, it is ground to 200-300 mesh.

[0020] Phosphor powder adopts commercially available SrAl 2 o 4 :Eu 2+ , Dy 3+ Long persistence phosphor. The mass ratio of phosphor powder to glass powder is 5:95.

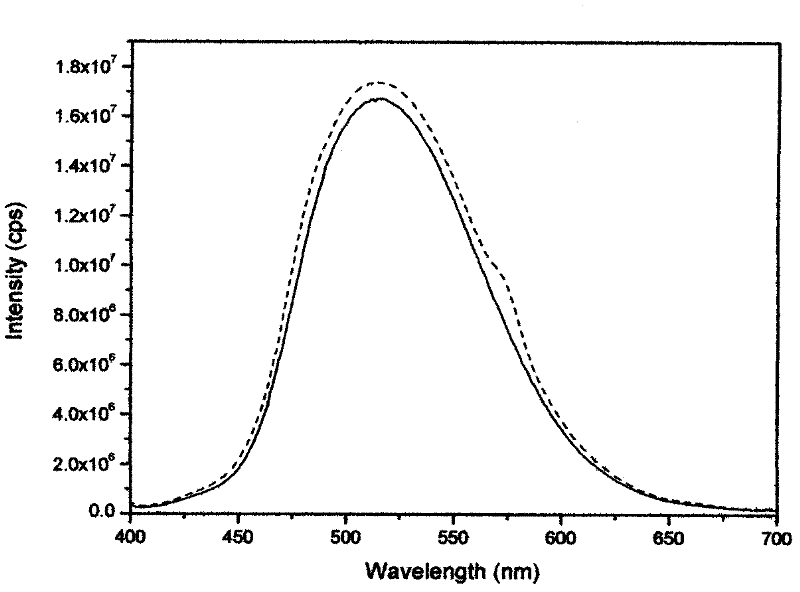

[0021] After mixing the above materials evenly, press them into a powder block under the pressure of a hydraulic press, melt at 700°C, anneal at 320°C, and then cool to room temperature with the furnace to obtain the sample of Example 1. Under the irradiation of 365nm ultraviolet light, the composite material emits strong yellow-green light with long afterglow characteristics, and its luminous intensity is basically the same as that of long afterglow phosphors with the same quality. figure 2 for SrAl 2 o 4 :E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com