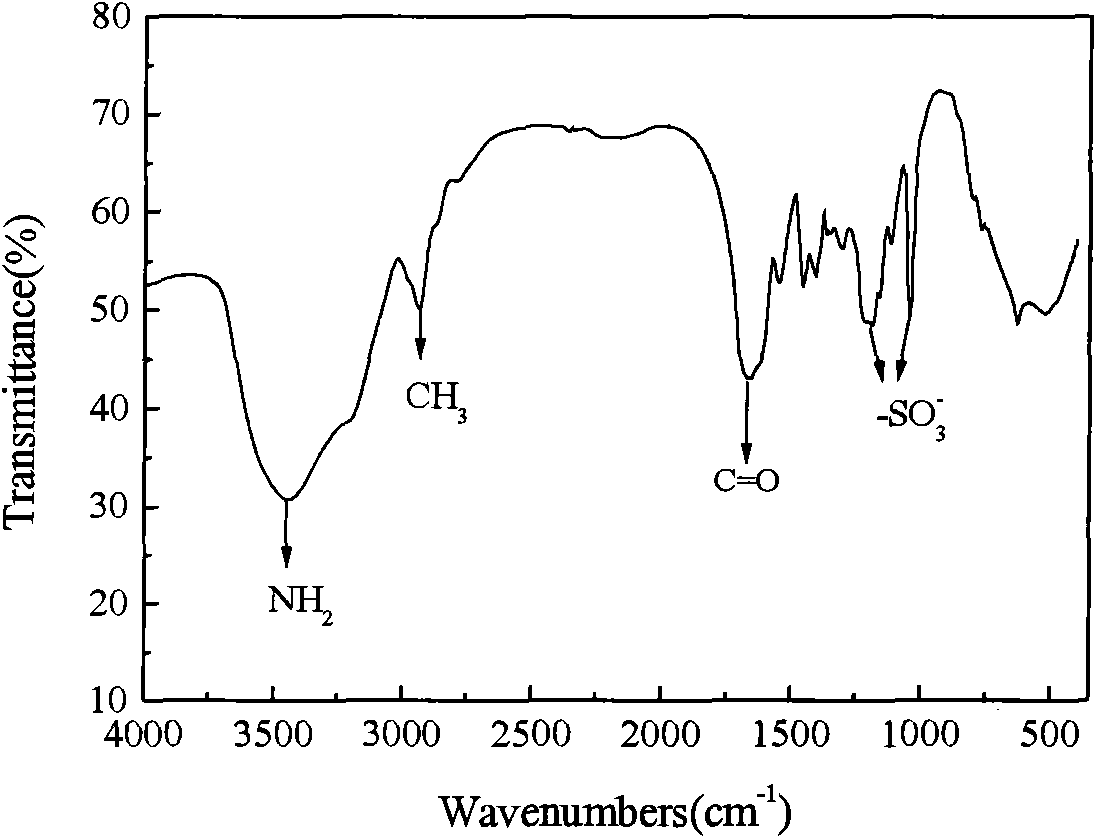

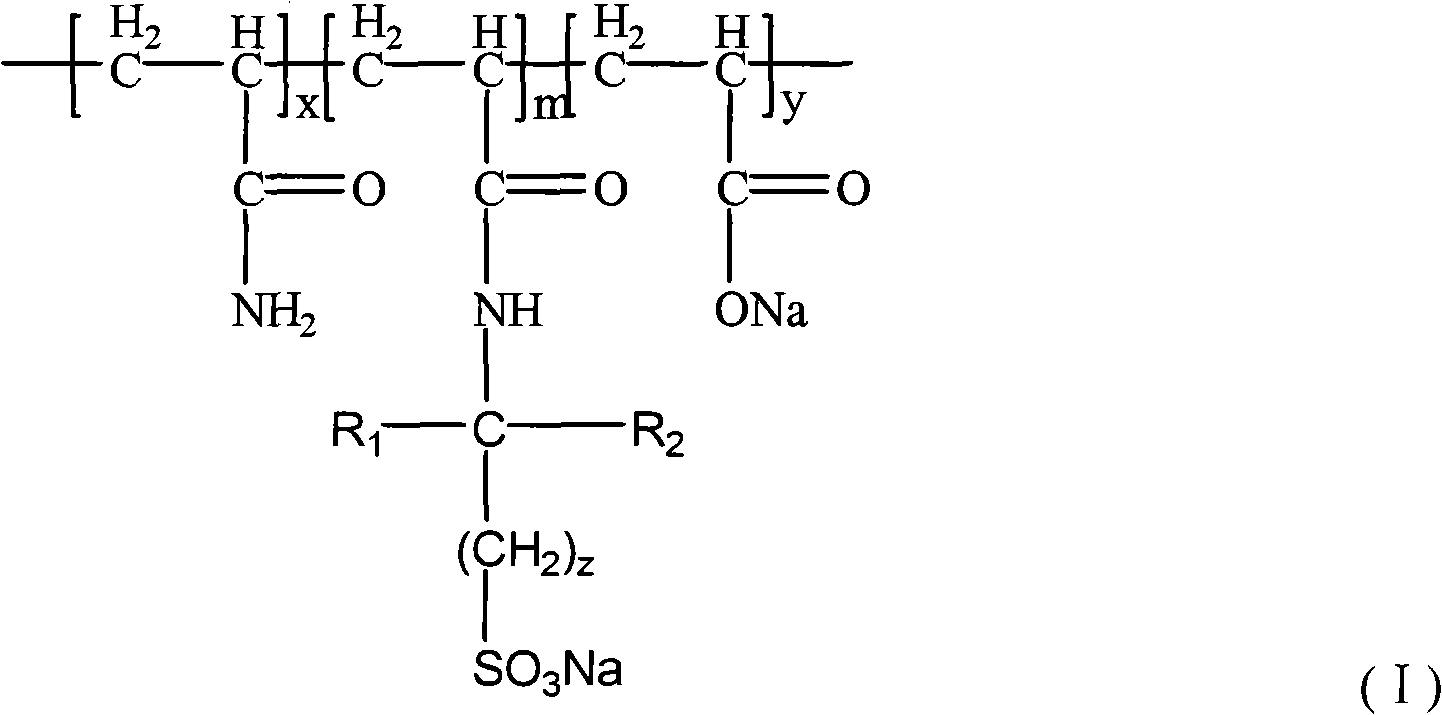

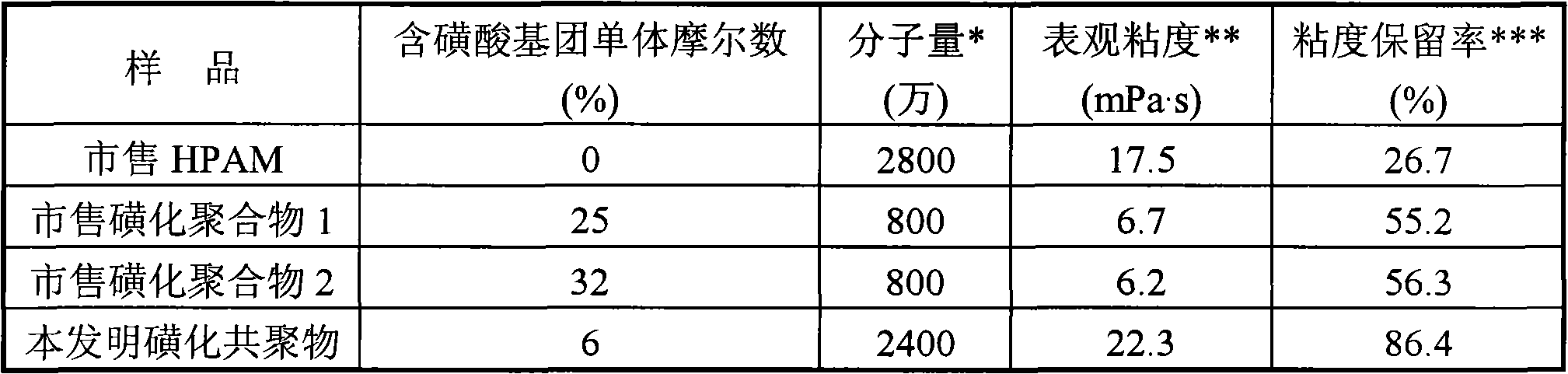

Sulphonated heat resistant and salt tolerant copolymer for oil field and preparation method thereof

A temperature-resistant, salt-resistant, copolymer technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of introducing monomers and less content into salt-resistant properties, introducing more monomers and their contents into copolymers, and polymerizing Acrylamide has problems such as poor temperature and salt resistance, and achieves the effect of improving salt resistance, facilitating industrial production, and improving economic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]Dissolve 0.75 parts of 2-acrylamido-2-methylpropanesulfonic acid in 425 parts of water, and use equimolar sodium hydroxide to dissolve the 2-acrylamido-2-methylpropanesulfonic acid solution under the condition of ice-water bath Neutralization; 74.25 parts of acrylamide are dissolved in the above-mentioned 2-acrylamido-2-methylpropanesulfonic acid solution to obtain a monomer solution, and acrylamide and 2-acrylamido-2-methylpropanesulfonic acid The mass ratio of the two monomers is 99:1, and the total mass fraction of the two monomers is 15%; then the monomer solution is poured into the reaction vessel, the temperature of the water bath is 5°C, and nitrogen gas is used to remove oxygen for 30 minutes; System, followed by: 0.3 parts of 0.6% N,N-dimethylaminoethyl methacrylate, 0.23 parts of 0.15% potassium persulfate solution, 0.13 parts of 0.09% sodium bisulfite solution; after 30 minutes of reaction, the temperature was raised to 50°C, continue the constant temperature ...

Embodiment 2

[0027] 8.75 parts of 2-acrylamido-2-methylpropanesulfonic acid were dissolved in 325 parts of water, and the 2-acrylamido-2-methylpropanesulfonic acid solution was dissolved with equimolar sodium hydroxide under the condition of ice-water bath Neutralization; 166.25 parts of acrylamide are dissolved in the above-mentioned 2-acrylamido-2-methylpropanesulfonic acid solution to obtain a monomer solution, and acrylamide and 2-acrylamido-2-methylpropanesulfonic acid The mass ratio of the two monomers is 95:5, and the total mass fraction of the two monomers is 35%; the monomer solution is poured into the reaction vessel, the temperature of the water bath is 15°C, and nitrogen gas is used to remove oxygen for 30 minutes; System, followed by: 5 parts of 5.25% N,N-dimethylaminoethyl methacrylate, 12.5 parts of 3.15% potassium persulfate solution, 12.5 parts of 15.75% sodium bisulfite solution; after 40 minutes of reaction, the temperature was raised to 45°C, continue the constant tempe...

Embodiment 3

[0029] Dissolve 10 parts of 2-acrylamido-2-methylpropanesulfonic acid in 400 parts of water, and use equimolar sodium hydroxide to dissolve the 2-acrylamido-2-methylpropanesulfonic acid solution under the condition of ice-water bath Neutralize, and then dissolve 90 parts of acrylamide in the above-mentioned 2-acrylamido-2-methylpropanesulfonic acid solution to obtain a monomer solution, and make acrylamide and 2-acrylamido-2-methylpropanesulfonic acid The mass ratio of the acid is 90:10, and the total mass fraction of the two monomers is 20%; the monomer solution is poured into the reaction vessel, the temperature of the water bath is 10° C., and nitrogen gas is used to remove oxygen for 45 minutes; then add 0.009% compound initiator System, followed by: 1 part of 0.27% N,N-dimethylaminoethyl methacrylate, 1 part of 0.27% potassium persulfate solution, 1 part of 0.54% sodium bisulfite solution; after 60 minutes of reaction, the temperature was raised to 40°C, continue the cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com