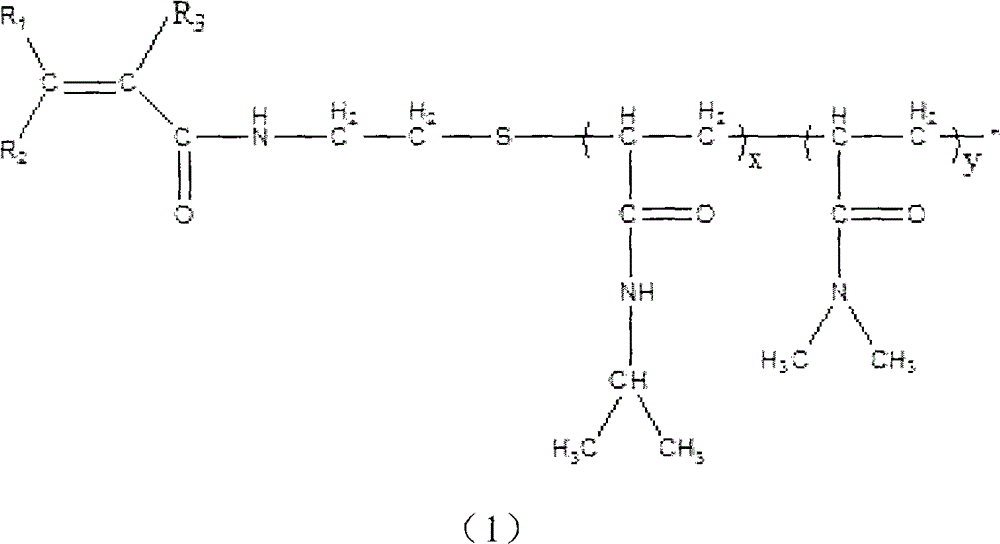

Thermothickening terpolymer, its preparation method and application

A heat-thickening terpolymer and terpolymer technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problem of easy hydrolysis of ester bonds, affecting polymer stability, unstable performance, etc. problems, achieve high apparent viscosity, good hydrolysis resistance, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Preparation of macromers:

[0044] Add 56.5g of isopropylacrylamide, 49.5g of N,N'-dimethylacrylamide, 0.9g of mercaptoethylamine hydrochloride and 450g of methanol into the reactor, mix well, and add azo 0.85 g of diisobutyronitrile was reacted at 65°C for 6 hours, and the solvent was distilled off under reduced pressure to obtain a solid, which was repeatedly purified three times with hot water at 65°C. Mix 45g of the purified solid, 2g of N,N'-dicyclohexylcarboimide, 60g of methacrylic acid and 300ml of dichloromethane, add dropwise 10% sodium carbonate solution, and react at 5°C for 2.5 hours. The solid was obtained after freeze-drying, and the solid was purified with a mixture of acetone and ether to obtain a macromonomer, which was designated as macromonomer B.

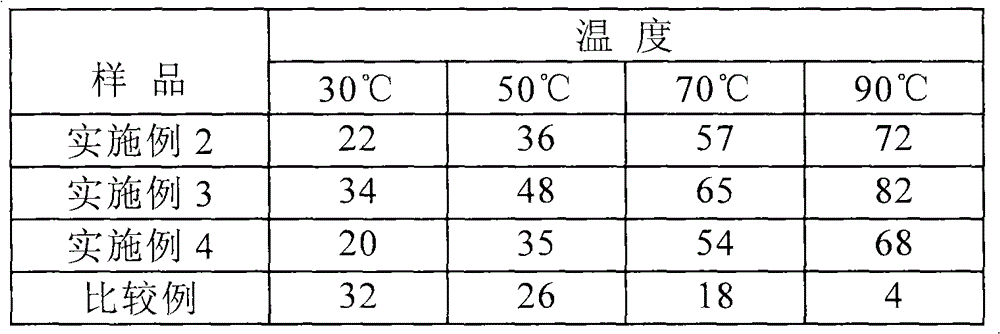

Embodiment 2

[0046] Add 220 parts by mass of deionized water to a reaction kettle equipped with a stirrer, a temperature controller, an air duct and a reflux condenser, and add 20 parts by mass of 2-acrylamide-2-methyl-1-propanesulfonate under stirring acid, after the solid is completely dissolved, use 30% sodium hydroxide solution to adjust the pH value to 10-12; add 50 parts by mass of acrylamide and 30 parts by mass of the macromer B prepared in Example 1, and stir to make all the solids After dissolving, use deionized water to adjust the monomer concentration to be 30%; adjust the initial temperature to be 10°C, feed nitrogen under stirring, and after 30 minutes, add 2 parts by mass of potassium persulfate solution (containing 2 wt% persulfuric acid potassium), 1.5 parts by mass of urea solution (wherein containing 2wt% urea), 2,2-azobis(2-imidopropyl) dihydrochloride (V50) of 0.03 parts by mass, after reacting for 5 hours Cooling, discharging, cutting, freeze-drying, and pulverization...

Embodiment 3

[0048] Add 220 parts by mass of deionized water to a reactor equipped with a stirrer, a temperature controller, an air duct and a reflux condenser, and add 25 parts by mass of 2-acrylamide-2-methyl-1-propanesulfonate under stirring acid, after the solid is completely dissolved, use 30% sodium hydroxide solution to adjust the pH value to 10-12; add 50 parts by mass of acrylamide and 25 parts by mass of the macromer B prepared in Example 1, and stir to make all the solids After dissolving, use deionized water to adjust the monomer concentration to be 30%; adjust the initial temperature to be 10°C, feed nitrogen under stirring, and after 30 minutes, add 2 parts by mass of potassium persulfate solution (containing 2 wt% persulfuric acid potassium), 1.5 parts by mass of urea solution (wherein containing 2wt% urea), 2,2-azobis(2-imidopropyl) dihydrochloride (V50) of 0.03 parts by mass, after reacting for 5 hours Cooling, discharging, cutting, freeze-drying, and pulverization to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com