Multi-piece multi-source horizontal hydride vapor phase epitaxy growth system

A hydride gas phase and epitaxial growth technology, which is applied in the growth of polycrystalline materials, single crystal growth, crystal growth, etc., can solve the problems that cannot meet the growth requirements of large quantities of GaN-based thick film materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

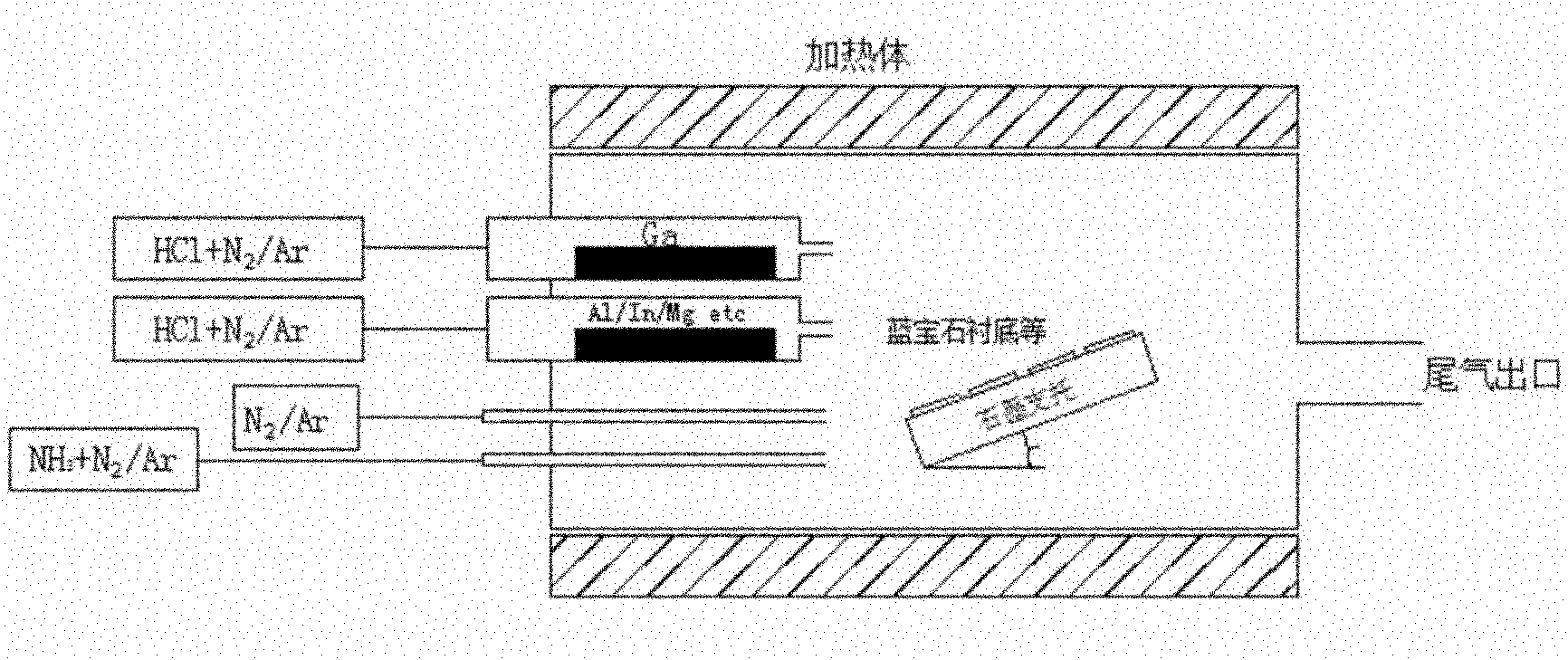

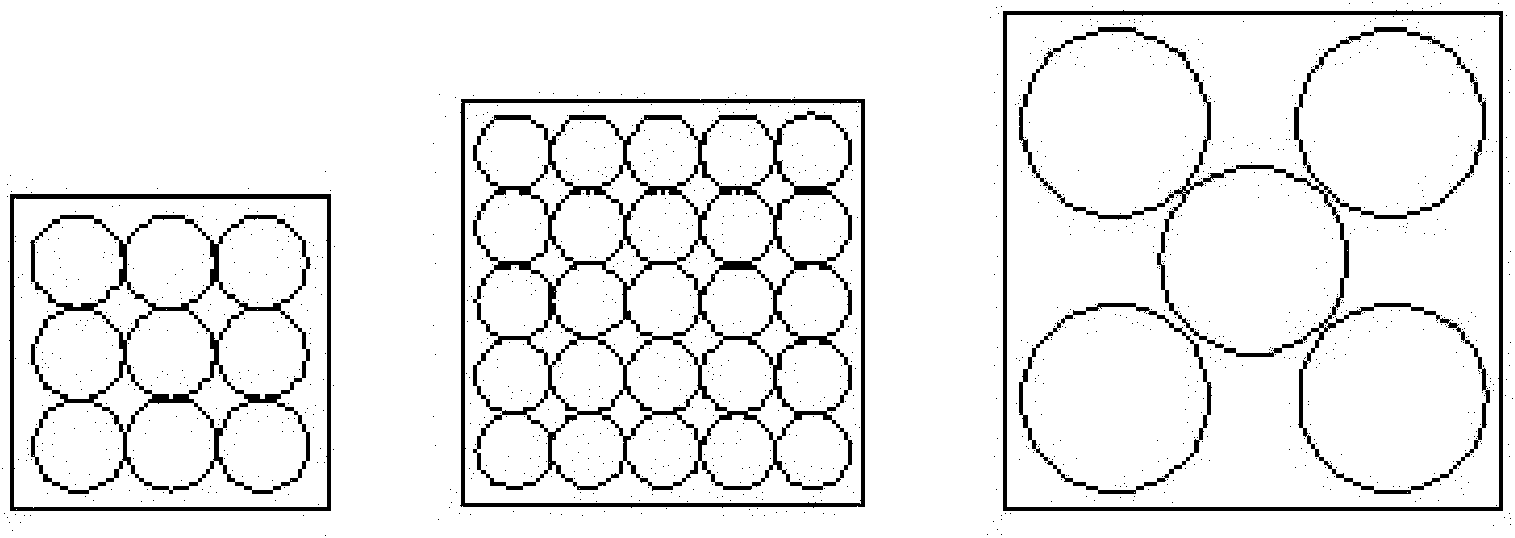

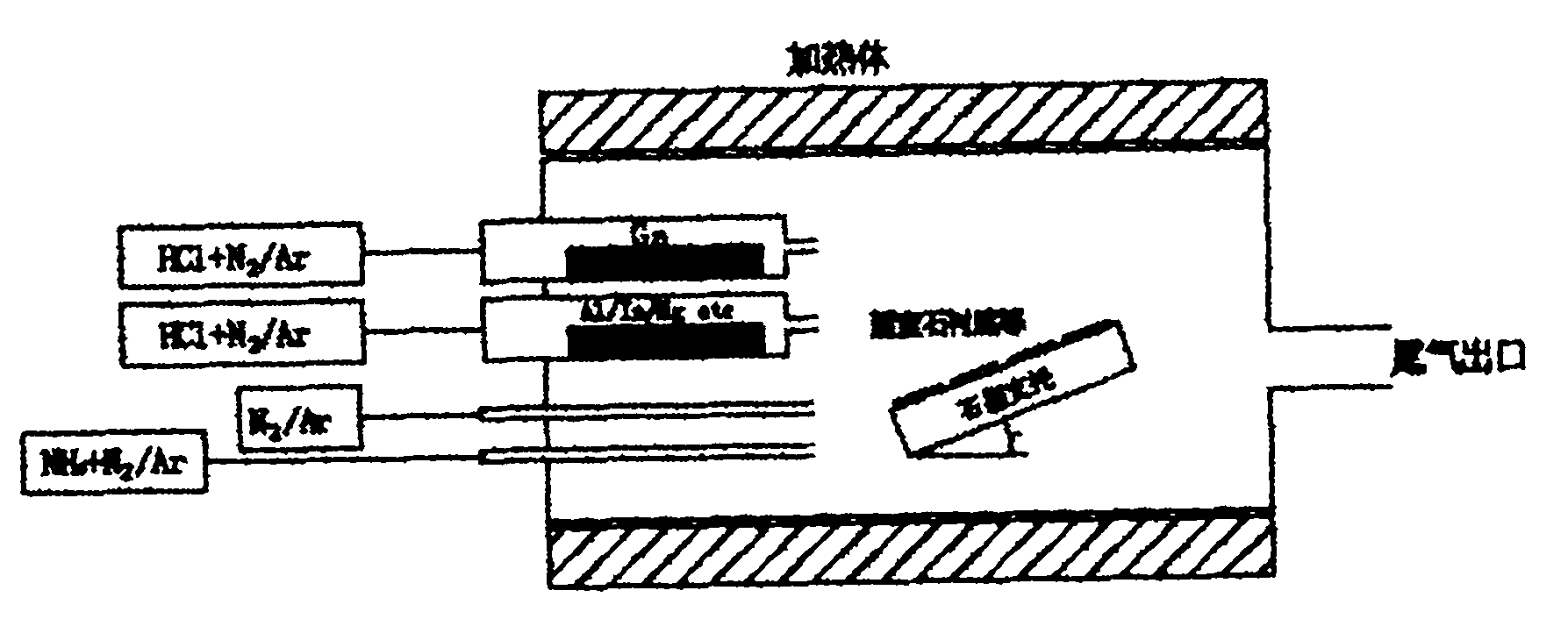

[0014] The HVPE system of the present invention includes several parts: a multi-channel gas transport system to realize the growth or doping of multiple semiconductor alloy materials; a specially designed multi-sheet graphite backing and a corresponding reaction source transport structure. The size of the graphite backing is based on the extension The number of growth substrates ranges from 60X60mm to 350X350mm, independent reaction source delivery pipelines, graphite support tilt / rotation structure, heating system for large-volume growth areas, and quartz shower heads to achieve large-scale growth of semiconductor materials. While increasing the output, it also guarantees the quality of the growth material; the new quartz reaction chamber structure, which is compact in structure, can also achieve HVPE growth of nitride materials when using a single temperature zone, which is energy-saving and efficient. The reaction chamber has a horizontal structure. One end of the reaction ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com