Method for hydrophilic charged ultrafiltration membrane by blending with AM-AMPS copolymer

An AM-AMPS and copolymer technology, applied in the field of membrane preparation, can solve the problems of cumbersome membrane preparation process, poor hydrophilicity of ultrafiltration membrane, unsuitable for composite ultrafiltration membrane, etc., and achieve lasting stability of hydrophilicity and negatively charged properties. , good hydrophilic and negatively charged properties, the effect of improving flux and anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

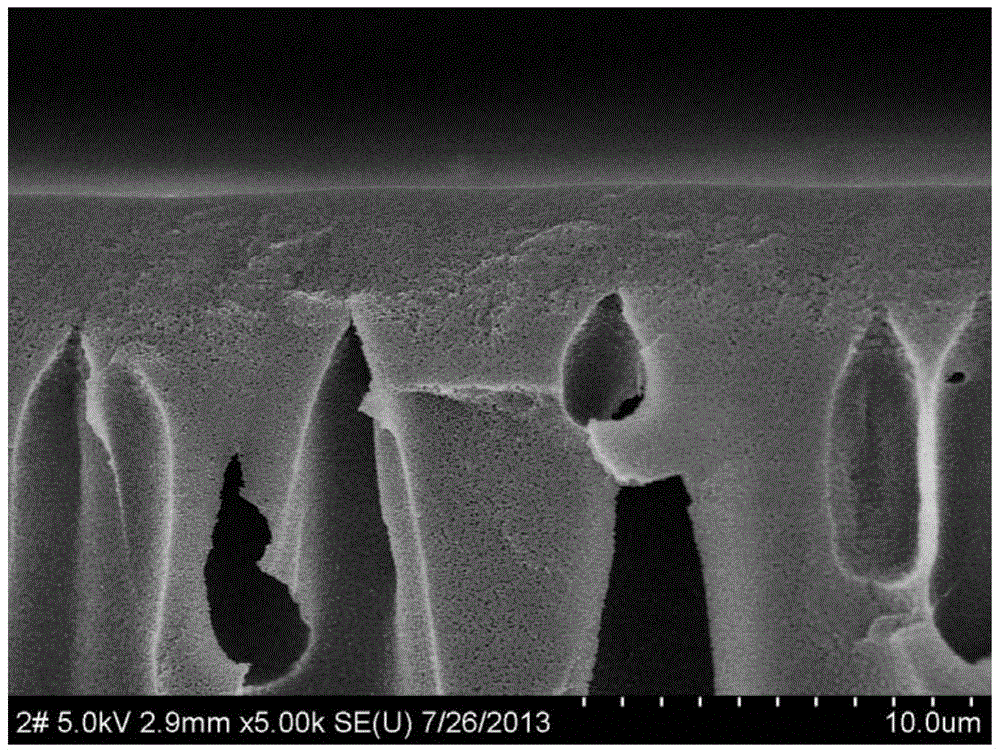

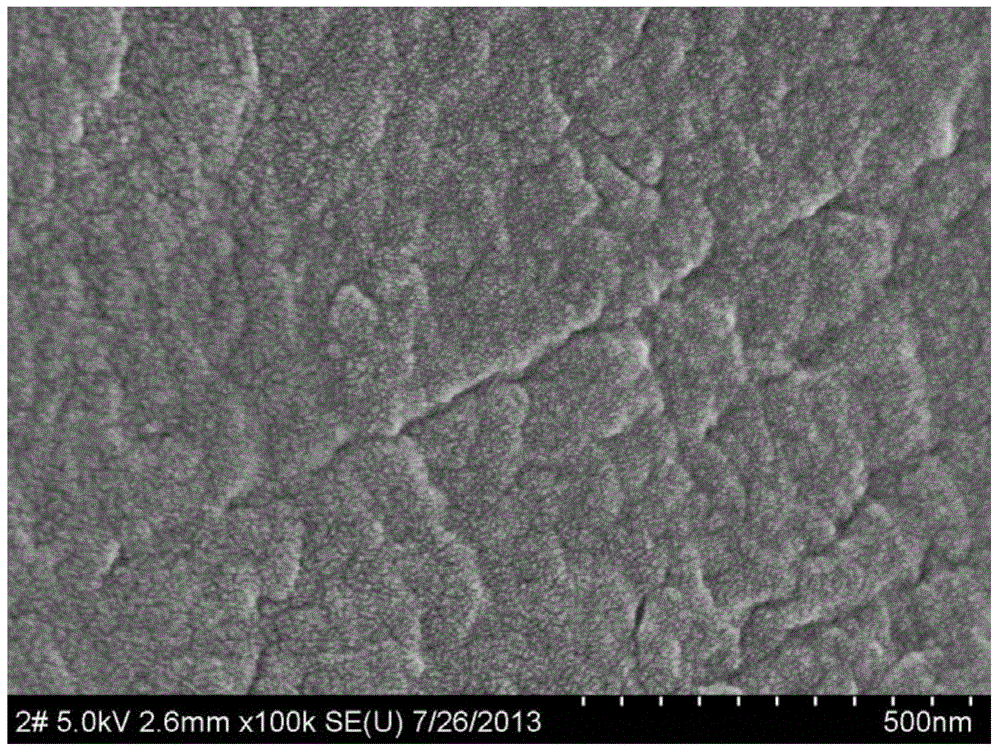

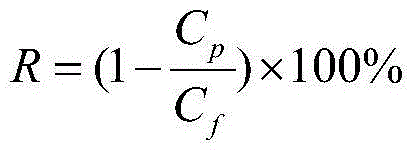

Image

Examples

preparation example Construction

[0039] (1) Preparation of AM-AMPS copolymer: Dissolve monomer AM and monomer AMPS in deionized water according to a certain ratio to prepare AM-AMPS solution (the temperature for preparing AM-AMPS solution can be 0-70°C), Then add a certain amount of initiator to initiate free radical polymerization reaction at a certain temperature (as the polymerization reaction progresses, the viscosity of the solution increases continuously, and even becomes a gel state), after the reaction has been carried out for a certain period of time, the reaction The water in the solution is removed to obtain AM-AMPS copolymers with different molecular weights;

[0040] AM and AMPS can be polymerized under the action of initiator to produce AM-AMPS copolymer. AM-AMPS copolymer is an effective anti-fouling agent, which contains more carboxylic acid groups and sulfonic acid groups, has high hydrophilicity, and can avoid the formation of fouling in the membrane separation process; at the same time, AM-...

Embodiment 1

[0076] (1) Dissolve AM and AMPS monomers with a total weight of 100 grams in 500 mL of deionized water at a ratio of 1:10 (mass ratio), stir to fully dissolve at 5 °C, and prepare a concentration of 200 g / L AM-AMPS solution, then add 0.1 gram (initiator dose and monomer total mass ratio is 1:1000) potassium persulfate initiator, initiate free radical polymerization reaction at 70 ℃, treat to react and carry out after 1 hour, will reacted The solution is removed by a rotary evaporator to obtain AM-AMPS copolymers with different molecular weights in a solid state;

[0077] (2) Add the prepared AM-AMPS copolymer to the solvent prepared by mixing 30% DMAC and 70% NMP by mass percentage, stir to dissolve it completely, and then add other additives PEG400 and polysulfone membrane material respectively In above-mentioned solvent, stirring and dissolving, be mixed with the film-forming liquid that contains AM-AMPS copolymer, leave standstill degassing 24 hours, wherein, the mass ratio...

Embodiment 2

[0081] (1) Dissolve AM and AMPS monomers in deionized water at a ratio of 10:1 (mass ratio), stir at 0°C to fully dissolve, and prepare an AM-AMPS solution with a concentration of 100g / L, and then add monomer The ammonium persulfate initiator of 10% of the total weight of the body was used to initiate free radical polymerization at 30 ° C. After the reaction was carried out for 5 hours, the reacted solution was removed by a rotary evaporator to obtain a solid AM-AMPS copolymer;

[0082](2) Add the prepared AM-AMPS copolymer to the DMF solvent, stir at 50°C to dissolve completely, then add the polyvinylidene fluoride film-making material to the above solvent, stir at 50°C to make it fully Dissolve, be mixed with the film-forming liquid that contains AM-AMPS copolymer, leave standstill defoaming 12 hours, wherein, the mass ratio of AM-AMPS copolymer, polyvinylidene fluoride film-making material and solvent is 5:22:100;

[0083] (3) The prepared film-forming solution containing A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com