Method for refining long chain binary acid by combining ultrafiltration and liquid-liquid extraction

A long-chain dibasic acid, filtrate technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry and other directions, can solve the problems of difficult recovery of organic solvents, many separation steps, low cost, etc. The effect of short process flow and low equipment requirements

Active Publication Date: 2012-05-30

CHINA PETROLEUM & CHEM CORP +1

View PDF2 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of the former is that the organic solvent is flammable, volatile, and toxic, and fireproof, explosion-proof, and poison-proof devices must be installed during post-treatment. Organic solvents are more expensive than water, volatile and easy to lose, and the cost is high. The advantage is that the crystal form is good and the crystal particles are large. , easy to separate; the disadvantage of the water treatment method is that the solubility of the dibasic acid in water is small, and the crystal shape and crystal particles are not as good as before.

Although several purification methods have been developed in domestic laboratories, the actual separation steps after industrial application reach 8 to 10 steps, and the economy is poor

In addition, in the existing process, the separation of pigments mostly adopts the method of multiple adsorption of activated carbon, which has defects such as many separation steps, high labor intensity, poor production environment, and difficult recovery of organic solvents in industrial applications.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

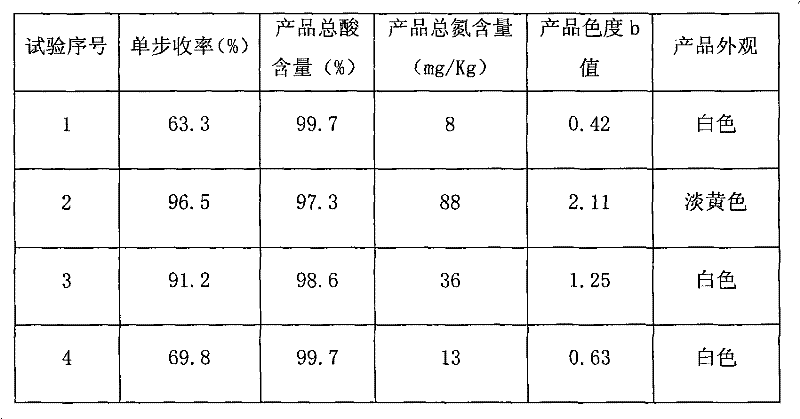

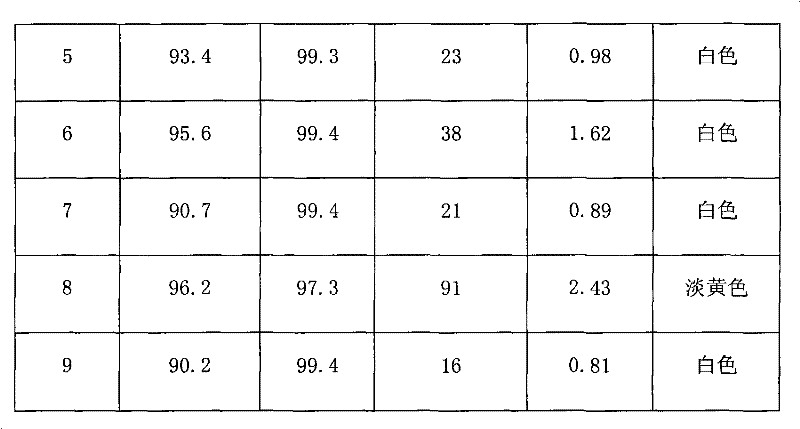

[0025] The following experiments can prove the remarkable technical effect of the present invention:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a method for refining long chain binary acid by combining ultrafiltration and liquid-liquid extraction, which comprises the following steps: a broth in a fermentation section is filtered through a microfiltration membrane to remove the solid particles, filtered through an organic ultrafilter membrane with 3000-50000 Dalton molecular flux, partial protein and pigment in a filtrate are removed, an ultrafiltrate and an extractant (monohydric alcohol with one or more C4-C12) are mixed, heated and acidified, certain pH value and temperature are controlled, the extractant and the ultrafiltrate are mixed and stirred for certain time, a process of liquid-liquid extraction is carried out, the extract phase is taken and cooled to obtain the crystallisate, the solvent is removed to obtain the purified product. The method of the invention has the characteristics of short process flow, low equipment requirement, less separation step, easy process control and the like.

Description

technical field [0001] The invention relates to a method for producing long-chain dibasic acid products by refining biological fermentation in the petrochemical field. The long-chain dibasic acid products produced by biological fermentation are purified by means of ultrafiltration and liquid-liquid extraction. Background technique [0002] Long-chain dodecanedioic acid is a fine chemical product with important and wide industrial uses. It is mainly used to synthesize high-grade engineering plastics nylon, nylon, and high-grade nylon hot melt adhesives and high-grade coatings for clothing. Dodecanedioic acid does not exist alone in nature, and it is difficult to produce synthetically in the chemical industry. The United States, Germany, Russia, Japan and other countries have conducted long-term research on the chemical synthesis of dodecanedioic acid, but so far, the chemical synthesis route is to use butadiene as the raw material for chemical synthesis, but it is not only H...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C51/48C07C51/47C07C51/42C07C55/21

Inventor 朱伟刘建新杨爱武陈韶辉缪军李丹杜鹃

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com