Paulownia leaf extract feed additive

A technology of feed additive and paulownia leaf, which is applied in the field of feed additive of paulownia leaf extract, can solve the problems of restrictions on popularization and application of paulownia leaf, increased manpower input, and large usage, so as to enhance animal immunity, improve feed conversion rate, and prevent The effect of animal digestive tract diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Accurately weigh 100kg of washed and dried paulownia leaves, crush them and pass through a 5-20 mesh sieve, add 800kg of water to soak for 1 hour, boil, extract for 1.5 hours, filter, add 400kg of water, boil, extract for 1 hour, and filter ; The two extracts were combined, mixed evenly, and concentrated into an extract with a relative density of 1.10. The paulownia leaf extract extract is sprayed and processed into the paulownia leaf extract dry powder through a spray drying tower. The technological conditions of the spray drying are: the tower inlet air temperature is 170°C, the outlet air temperature is 80°C, and the inlet air pressure is 40Mpa. The moisture content of the obtained Paulownia leaf extract dry powder is 2.62%. Then the Paulownia leaf extract dry powder is mixed with the chaff powder according to the ratio of 1:5 to prepare the Paulownia leaf extract feed additive.

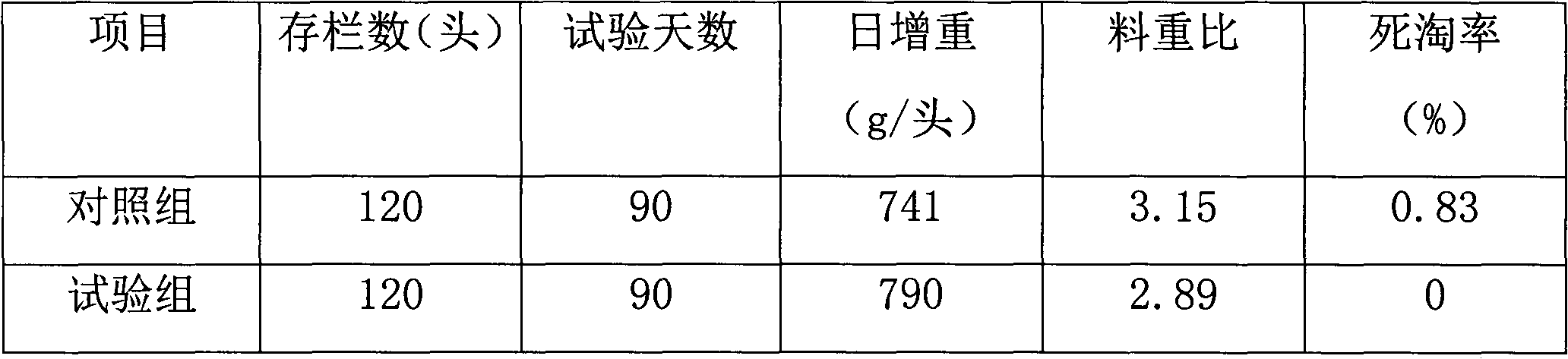

[0015] In a pig farm in Longyan, Fujian, the Paulownia leaf extract feed additive pre...

Embodiment 2

[0019] Accurately weigh 100kg of washed and dried paulownia leaves, crush them, pass through a 5-20 mesh sieve, add 1000kg of water to soak for 1 hour, boil, extract for 2 hours, filter, add 500kg of water, boil, extract for 1 hour, and filter; combine The two extracts were mixed evenly and concentrated into an extract with a relative density of 1.15. The paulownia leaf extract extract is sprayed and processed into the paulownia leaf extract dry powder through a spray drying tower. The technological conditions of the spray drying are: the inlet air temperature is 180°C, the outlet air temperature is 85°C, and the inlet air pressure is 40Mpa. The moisture content of the obtained Paulownia leaf extract dry powder was 2.81%. Then, the dry powder of the Paulownia leaf extract and silicon dioxide are mixed according to the ratio of 1:4 to prepare the Paulownia leaf extract feed additive.

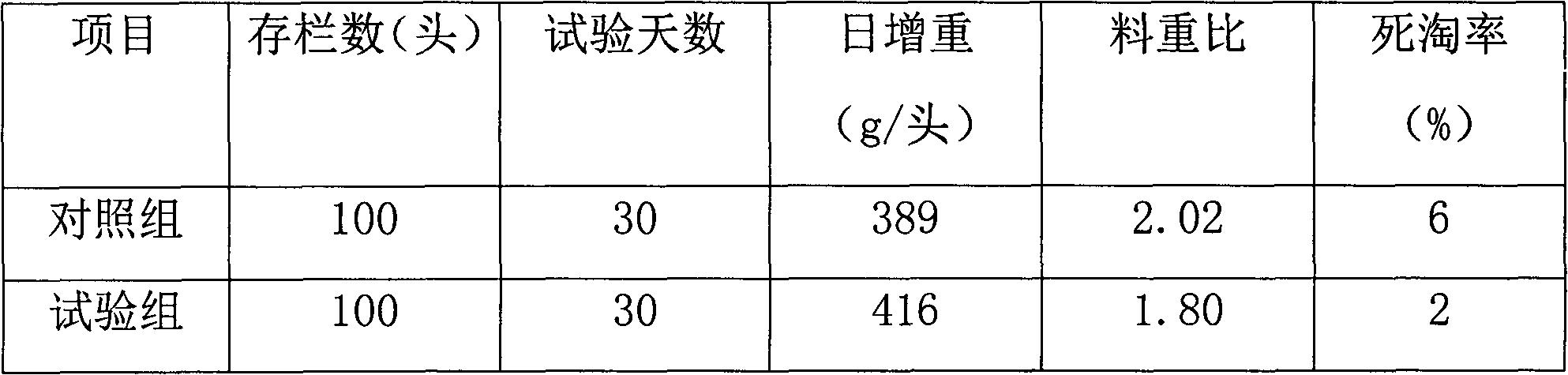

[0020] In a pig farm in Qingdao, Shandong, the Paulownia leaf extract feed additive prepare...

Embodiment 3

[0024] Accurately weigh 100kg of washed and dried paulownia leaves, crush them, pass through a 5-20 mesh sieve, add 1200kg of water to soak for 1 hour, boil, extract for 1.5 hours, filter, add 600kg of water, boil, extract for 1.5 hours, and filter ; The two extracts were combined, mixed, and concentrated into an extract with a relative density of 1.20. The paulownia leaf extract extract is sprayed and processed into the paulownia leaf extract dry powder through a spray drying tower. The technological conditions of the spray drying are as follows: the air inlet temperature of the tower is 190°C, the air outlet temperature is 90°C, the air inlet pressure is 40Mpa, and the moisture content of the obtained Paulownia leaf extract dry powder is 2.74%. Then the dry powder of the Paulownia leaf extract is mixed with the calcium carbonate according to the ratio of 1:6 to prepare the Paulownia leaf extract feed additive.

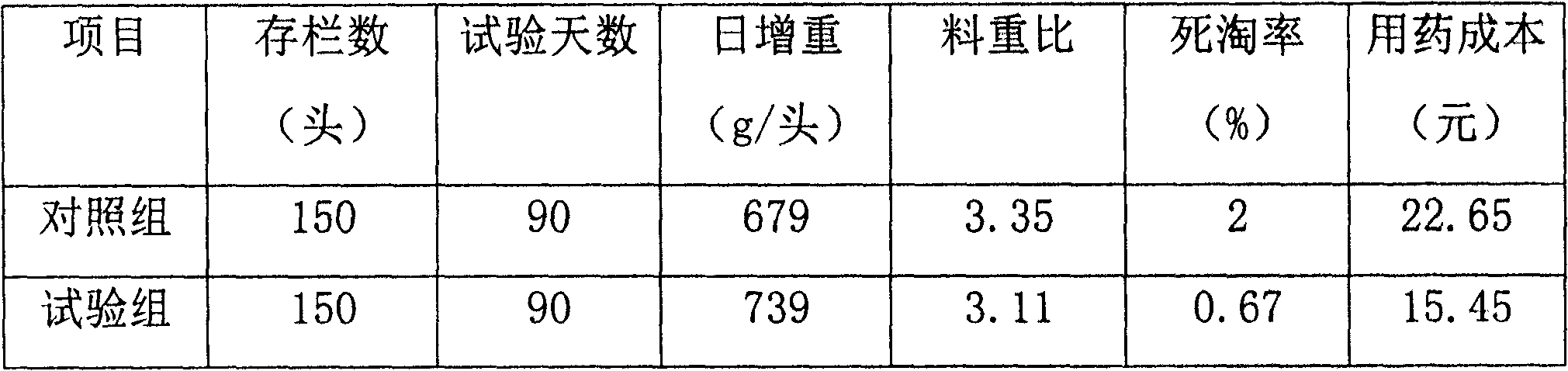

[0025] In a pig farm in Weifang, Shandong, the Paulownia leaf ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com