Method for preparing graphene

A technology of graphene and graphene powder, which is applied in the field of preparation of graphene powder products, and can solve the problems of physical and chemical performance loss, time-consuming, long process flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

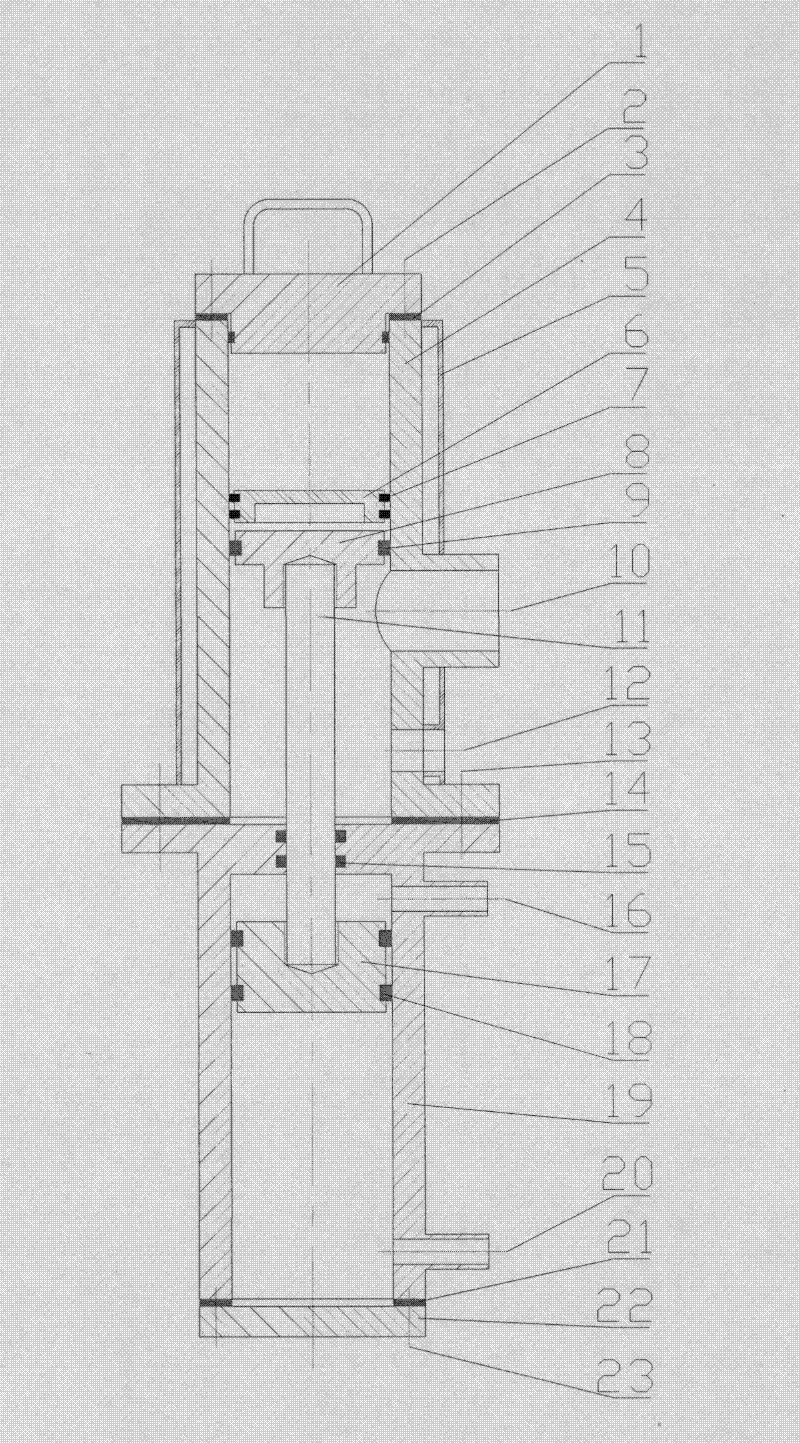

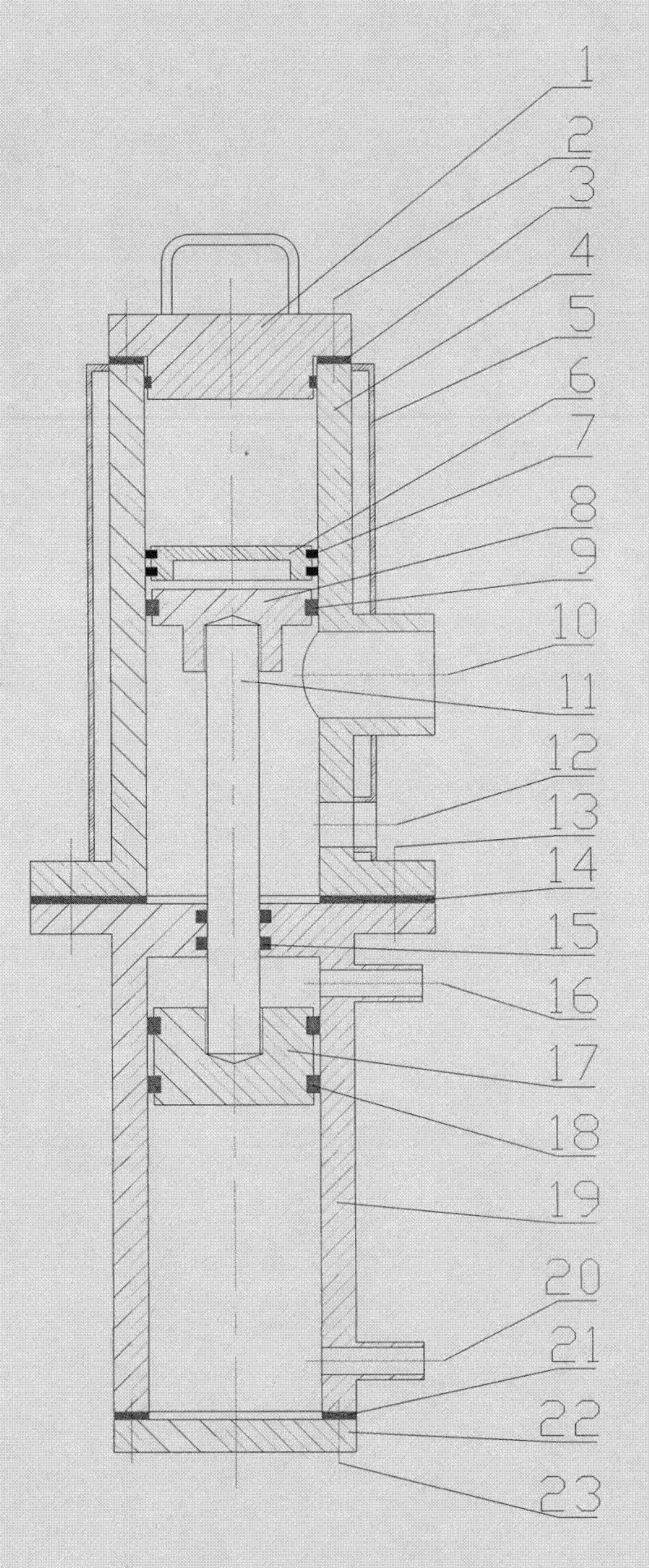

Image

Examples

Embodiment 1

[0024] Weigh 100 grams of micropowder graphite and 20 grams of ethanol respectively, mix the micropowder graphite and ethanol evenly, and then place them in a high-temperature autoclave. Seal the high-temperature autoclave well, then heat the high-temperature autoclave to 250 ° C, and keep it for 10 seconds, quickly remove the pressure of the high-temperature autoclave, take out the material in the autoclave, which is the primary product of graphene, and wash the primary product with ethanol repeatedly, Centrifuge and dry in vacuum at 200°C for 10 minutes to obtain the final graphene powder product. It is obtained through testing that the graphene content of less than 5 layers in the final graphene powder sample accounts for 90%.

Embodiment 2

[0026] Choose hexane as the organic solvent, expandable graphite as the carbonaceous raw material, mix 500 grams of expandable graphite and 1500 grams of hexane evenly, and then place it in a high-temperature autoclave. Seal the high-temperature autoclave well, heat it to 240°C, keep it for 300 seconds, quickly release the pressure of the high-temperature autoclave, take out the contents in the autoclave, weigh 400 grams of this substance and 1200 grams of hexane, mix them evenly, and then place In the high-temperature autoclave, seal the high-temperature autoclave, heat it to 240°C, keep it for 300 seconds, quickly remove the pressure from the high-temperature autoclave, take out the contents of the autoclave, weigh 300 grams of this substance, and 900 grams of hexane to make They are evenly mixed, then placed in a high-temperature autoclave, sealed the high-temperature autoclave, and heated to 240 ° C, kept for 300 seconds, quickly unloaded the pressure of the high-temperatur...

Embodiment 3

[0028] Weigh 40 grams of high-carbon graphite and 40 grams of dimethyl butane respectively, mix the high-carbon graphite and dimethyl butane evenly, and then place them in a high-temperature autoclave. Seal the high-temperature autoclave well, and heat it to 230°C, keep it for 150 seconds, quickly release the pressure of the high-temperature autoclave, take out the contents in the autoclave, weigh 20 grams of this substance and 20 grams of dimethyl butane, and mix them evenly , and then placed in a high-temperature autoclave, and heated to 230 ° C, kept for 150S, quickly unloaded the pressure of the high-temperature autoclave, took out the contents of the autoclave, and then weighed 10 grams of this substance and 10 grams of dimethylbutane to make them Mix evenly, then place in a high-temperature autoclave, seal the high-temperature autoclave, and heat it to 230 ° C, keep it for 150 seconds, quickly remove the pressure from the high-temperature autoclave, take out the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com