High-ammonia-nitrogen waste water resource recovery technology

A resource-based, high-ammonia-nitrogen technology, applied in the field of high-ammonia-nitrogen waste water recycling, can solve problems such as the paralysis of the ammonia removal system and the impact on the quality of recycled products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

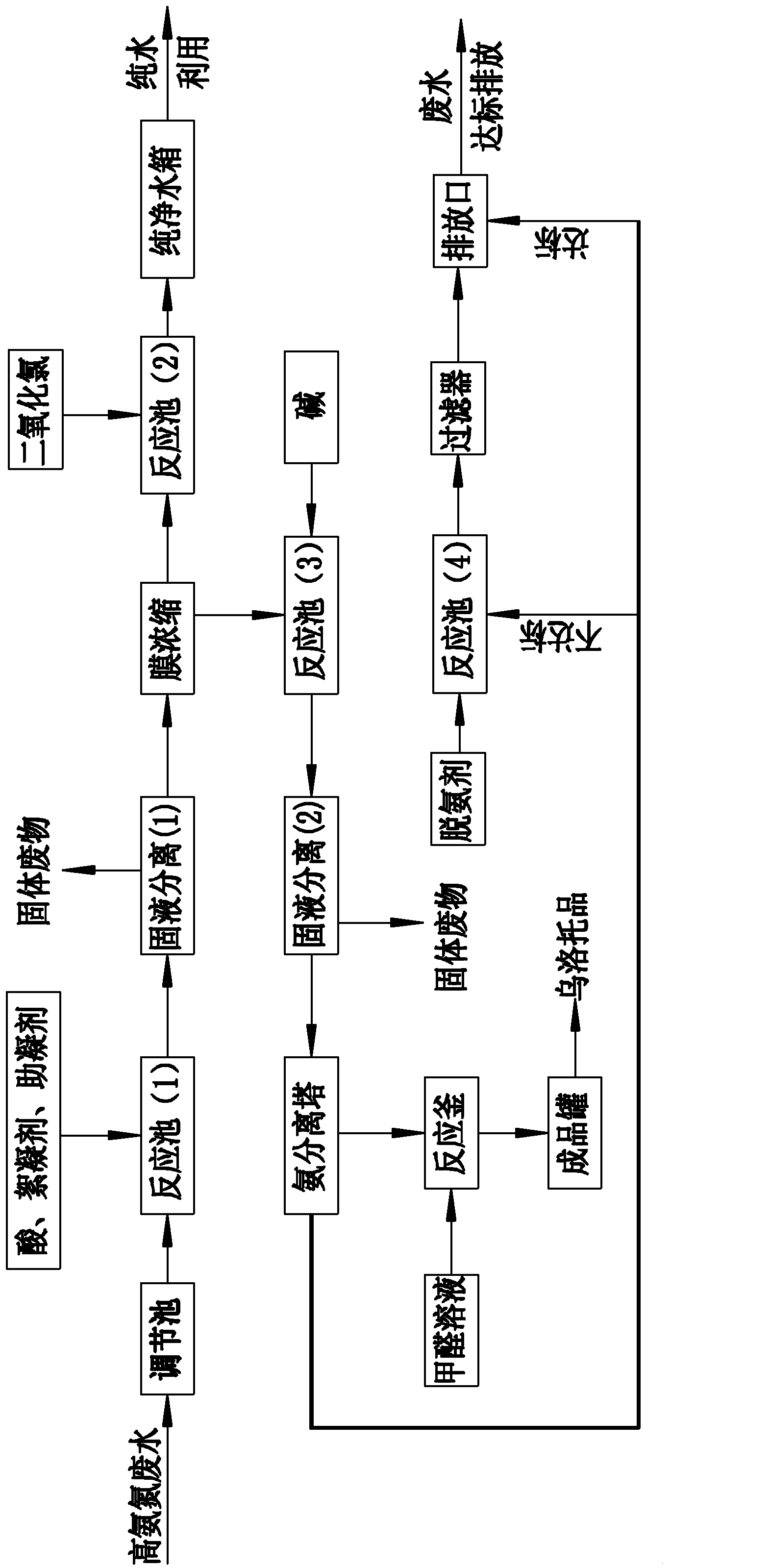

[0015] The specific embodiment of the present invention is illustrated as follows in conjunction with process flow diagram:

[0016] The amount of waste water is 200m 3 / d. The content of ammonia nitrogen in the waste water is 10000 mg / L; use the high ammonia nitrogen waste water recycling technology of the present invention to carry out waste water recycling treatment. The specific method is as follows:

[0017] 1. 200m 3 / d of high ammonia nitrogen wastewater first enters the regulating tank for water volume regulation, using a lift pump according to 10m 3 Inject waste water into the reaction tank (1) at a flow rate of / h, and at the same time inject sulfuric acid solution into the reaction tank to adjust the pH value of the waste water to 6, and add a polyacrylamide solution with a concentration of 1% and a polyaluminum chloride solution with a concentration of 10%. Enter the reaction pool (1) for reaction and mixing, and the reaction pool (1) is a continuous water inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com