Compound fertilizer special for sugarcanes and production method thereof

A production method and compound fertilizer technology, applied in the direction of application, fertilization device, fertilizer mixture, etc., can solve the problems of not being able to meet the fertilizer requirements of sugarcane well and not being involved, and achieve high yield and income benefits, wide application, and The effect of high sugar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Prepare 16% (6-5-5) of nitrogen, phosphorus, and potassium total nutrients, 15% organic matter in organic fertilizer, and 1000 kg of sugarcane special fertilizer with 15% compound amino acid (6-5-5 respectively refers to N, P 2 O5, K 2 The nutrient percentage content of O, the same below).

[0049] Raw material formula ratio: 135 kg of urea (containing N as 46.0%), 280 kg of calcium magnesium phosphate fertilizer (containing P 2 o 5 18.0%, 9% for Mg, 28.4% for Ca, 12.7% for Si), 80 kg of potassium sulfate (containing K 2 O is 50.0%, S is 17.0%, borax is 1 kg (B is 11%), zinc sulfate heptahydrate is 0.5 kg (Zn is 23%), anhydrous copper sulfate is 0.5 kg (Cu is 25%), 30 kg of compound amino acids (according to 50% organic matter), 1,000 kg of organic fertilizer raw materials, and 0.1 kg of decomposed strains for bio-organic fertilizers.

[0050] The compound amino acid is made by putting animal fur into an enamel tank, adding 80~98% concentrated sulfuric acid to reac...

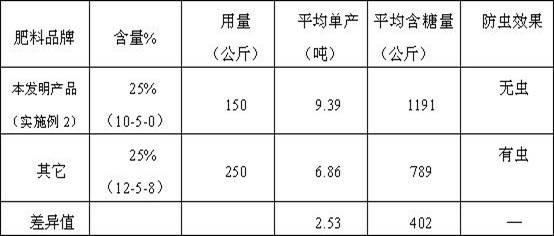

Embodiment 2

[0053] Prepare 1,000 kg of special fertilizer for sugarcane with 25% of total nitrogen, phosphorus and potassium nutrients (10-5-10), 20% of organic matter in organic fertilizer, and 15% of compound amino acid.

[0054] Raw material formula ratio: 230 kg of urea (containing N as 46.0%), 280 kg of calcium magnesium phosphate fertilizer (containing P 2 o 5 18.0%, 9% Mg, 28.4% Ca, 12.7% Si), 200 kg potassium sulfate (K 2 O is 50.0%, S is 17.0%, borax is 1 kg (B is 11%), zinc sulfate heptahydrate is 0.5 kg (Zn is 23%), anhydrous copper sulfate is 0.5 kg (Cu is 25%), 30 kg of compound amino acids (50% of organic matter), 500 kg of organic fertilizer raw materials, and 0.05 kg of decomposed strains for bio-organic fertilizers.

[0055] The compound amino acid is made by putting slaughterhouse waste and silkworm cocoon waste residue into the enamel tank, adding 80-98% concentrated sulfuric acid to react for 3-18 hours, after the animal fur is basically dissolved, and then adjustin...

Embodiment 3

[0058] Prepare 1,000 kg of sugarcane special fertilizer with 30% of total nitrogen, phosphorus and potassium nutrients (13-6-12), 30% of organic matter in organic fertilizer, and 15% of compound amino acid.

[0059] Raw material formula ratio: 290 kg of urea (including 46.0% N), 320 kg of calcium magnesium phosphate fertilizer (including P 2 o 5 18.0%, 9% Mg, 28.4% Ca, 12.7% Si), 250 kg potassium sulfate (50.0% K2O, 17.0% S), 1 kg borax (B 11%), 0.5 kg of zinc sulfate heptahydrate (calculated as 23% containing Zn), 0.5 kg of anhydrous copper sulfate (calculated as 25% containing Cu), 30 kg of compound amino acids (calculated as 50% containing organic matter), organic fertilizer 1500 kg of raw materials, 0.15 kg of decomposed strains for bio-organic fertilizers.

[0060] The compound amino acid is made by putting animal fur and waste bean dregs into an enamel tank, adding 80-98% concentrated sulfuric acid to react for 3-18 hours, after the animal fur is basically dissolved, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com