Preparation method of enclosed type aromatic isocyanate aqueous dispersion

An isocyanate and aromatic technology, which is applied in the field of preparation of blocked isocyanate aqueous dispersions, can solve the problems of poor stability of aromatic isocyanate aqueous dispersions, and achieve the effects of simplifying the bonding process, saving costs, and improving bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

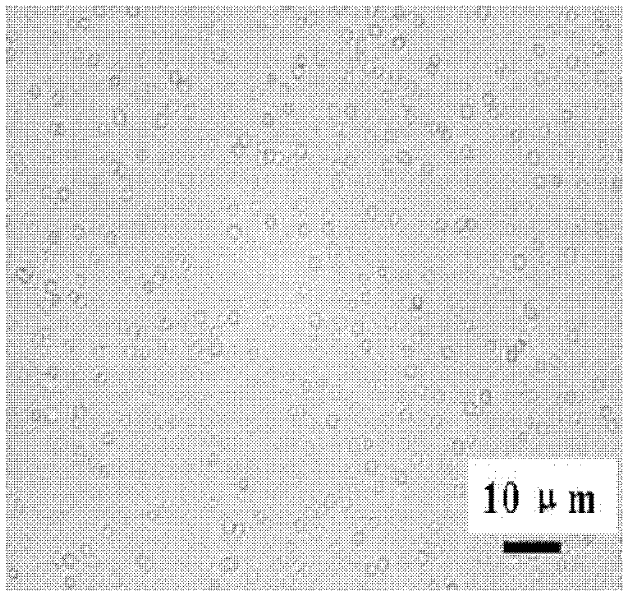

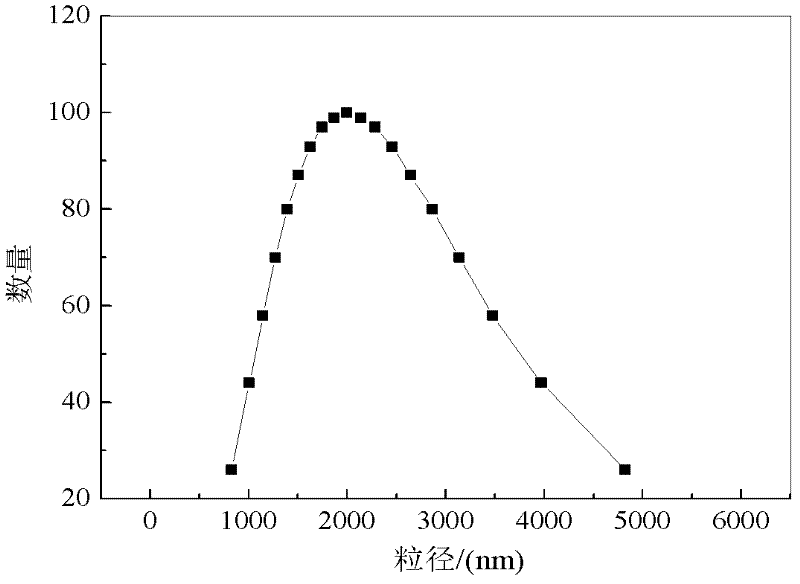

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment one: the preparation method of the blocked aromatic isocyanate aqueous dispersion, characterized in that the preparation method of the blocked aromatic isocyanate aqueous dispersion is realized by the method:

[0021] 1. Dry the polyol at 60~100℃;

[0022] 2. Add 0.5 to 1.5 mol of polyol and 0.2 to 0.8 mol of dimethylolpropionic acid (DMPA) to 10 to 250 mL of solvent A, stir for 10 to 60 minutes, and then pour in nitrogen at a flow rate of 1 to 5 mL / min for 15~ 45 minutes (the purpose is to remove the oxygen in the solution), then heat to 40~90℃, keep for 15~45 minutes;

[0023] 3. Then add 0.5-2mol aromatic isocyanate dropwise, the dropping rate is controlled at 2-5s / drop, and then react at 50-95℃ for 0.5-7 hours;

[0024] 4. Then add the blocking agent at 25~70℃, the amount of blocking agent is 1~1.5 times of the free isocyanate content;

[0025] 5. Add 0.5-2mol of triethylamine at 35~55℃, then add 10~500mL deionized water, emulsify at 30℃ for 2~5 hours, st...

specific Embodiment approach 2

[0027] Specific embodiment two: This embodiment is different from specific embodiment one in that the polyol in step one is polyester polyol or polyether polyol. The other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific embodiment three: this embodiment is different from specific embodiment one in that: the polyol in step one is polyoxypropylene glycol, polyoxyethylene glycol, polyethylene glycol, polyethylene adipate two Alcohol, polycaprolactone or poly 2,3-dimethyl-2,3-butanediol. The other steps and parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com