Method for preparing sulforaphane by using glucoerucin

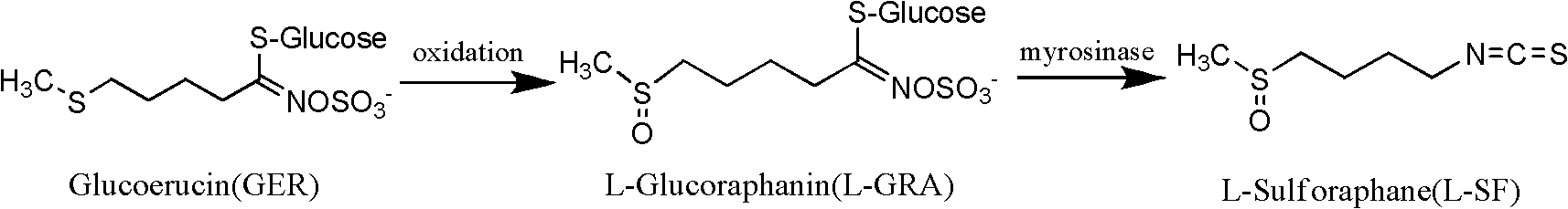

A technology of aruginin and sulforaphane, applied in the field of preparation of sulforaphane, capable of solving the problems of high raw material cost and low yield of sulforaphane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of arugula glycoside glucoerucin: take 100g of arugula seeds, inactivate the enzyme at 100°C for 30 minutes, pulverize, add 800ml of boiling water, adjust the pH to 7.0 with citric acid-sodium citrate buffer, stir under boiling water for 20 minutes, after suction filtration, Add 500ml of boiling water to the filter cake and continue to stir for 20 minutes, and combine the two extracts. The extract was filtered and spin-dried at 30° C. to obtain 10.56 g of crude aruginoside.

[0025] The preparation of glucose sulforaphane L-glucoraphanin: the above-mentioned 10.56g aruginin crude product, 5.18g (+)-L-diethyl tartrate, 3.57g titanium tetraisopropoxide, 500ml methanol, ethanol and ethyl acetate ( Volume ratio 3:2:5) mixture, warming up to 40°C, mixing and stirring for 40min, cooling to 0°C, adding 37ml hydrogen peroxide (30%) dropwise within 1 hour, stirring and reacting for 2 hours, adding 500ml deionized water and stirring After 1 hour, the aqueous phase wa...

Embodiment 2

[0029] Preparation of arugula glucoerucin: take 100g of arugula seeds, inactivate the enzyme at 110°C for 40 minutes, pulverize, add 900ml of boiling water, adjust the pH to 6.0 with acetic acid-sodium acetate buffer, stir under boiling water for 30 minutes, and filter the cake Add 500ml of boiling water and continue stirring for 30 minutes, and combine the two extracts. The extract was filtered and spin-dried at 50° C. to obtain 9.71 g of crude aruginoside.

[0030]The preparation of glucose sulforaphane L-glucoraphanin: the above-mentioned 9.71g aruginin crude product, 4.76g (+)-L-diethyl tartrate, 3.28g tetraisopropoxytitanium, 500ml methanol, ethanol and ethyl acetate ( Volume ratio 4:2:4) mixture, warming up to 50°C, mixing and stirring for 50min, cooling to 5°C, adding 32ml cumene hydroperoxide (30%) dropwise within 2 hours, stirring for 3 hours, adding 500ml of deionized water was stirred for 2 hours, and the aqueous phase was separated. The water phase is adsorbed by...

Embodiment 3

[0034] Preparation of arugula glycoside glucoerucin: Take 100g of arugula seeds, inactivate the enzyme at 120°C for 50 minutes, crush them, add 1L of boiling water, and wash with Na 2 HPO 4 -NaH 2 PO 4 Adjust the pH of the buffer solution to 8.0, stir under boiling water for 50 minutes, and after suction filtration, add 500 ml of boiling water to the filter cake and continue stirring for 50 minutes, and combine the two extracts. The extract was filtered and spin-dried at 40° C. to obtain 10.48 g of crude aruginoside.

[0035] The preparation of glucose sulforaphane L-glucoraphanin: the above-mentioned 10.48g aruginin crude product, 5.14g (+)-L-diethyl tartrate, 3.54g titanium tetraisopropoxide, 500ml methanol, ethanol and ethyl acetate ( Volume ratio 5:2:3) mixture, warming up to 60°C, mixing and stirring for 60min, cooling to 0°C, adding dropwise 34ml of dicumyl hydroperoxide (30%) within 3 hours, stirring and reacting for 5 hours, Add 500 ml of deionized water and stir f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com