Projection objective structural optimization method for reducing deformation of extreme ultra-violet lithography system

A technology of extreme ultraviolet lithography and optimization method, which is applied in the field of deformation control of extreme ultraviolet lithography objective lens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

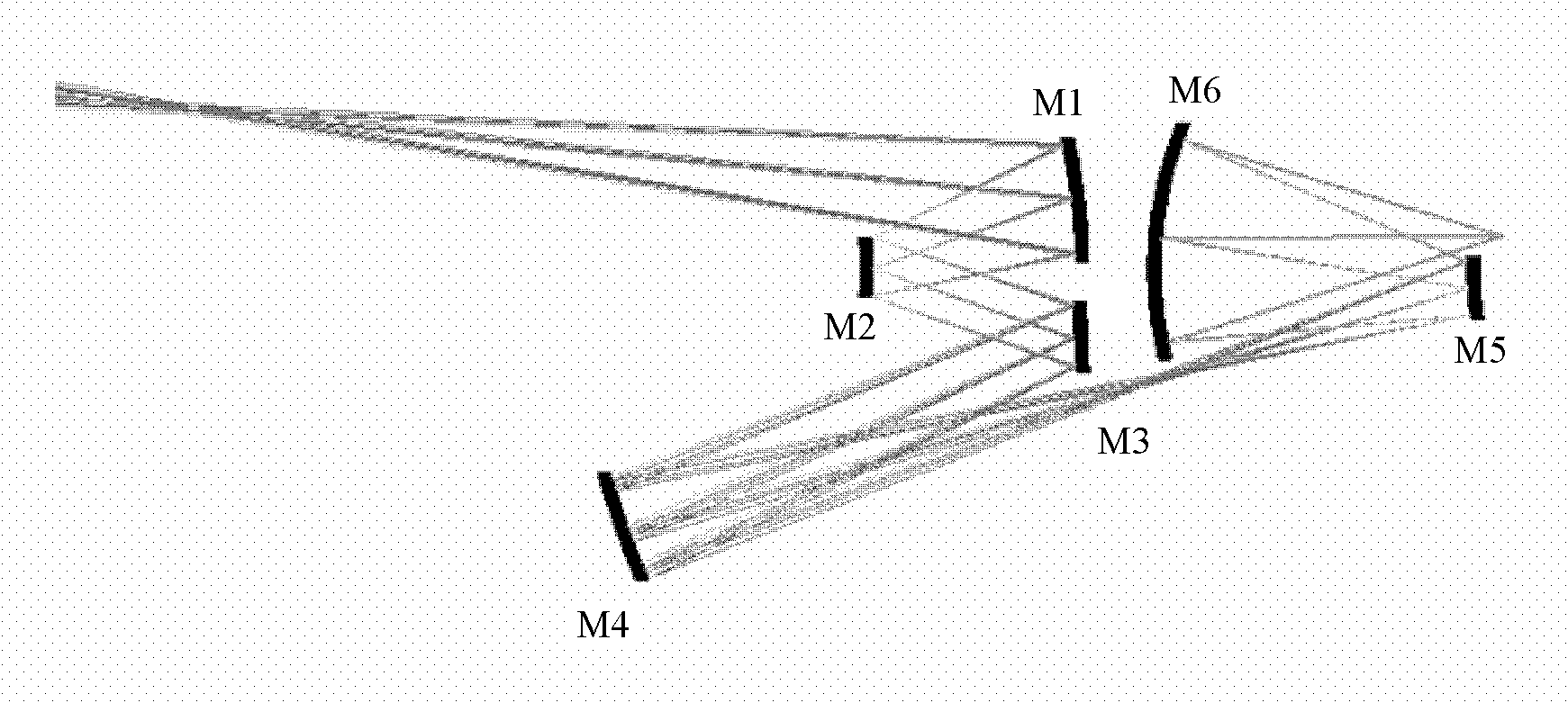

[0022] In order to meet the needs of 22nm industrial extreme ultraviolet lithography, the image square aperture is designed to reach 0.3, the image square field of view width reaches 1.5mm, and the six-sided reflective projection objective lens system, such as figure 1 shown. Name the mirror close to the mask as M1, and name the other mirrors along the optical path, and name the last mirror M6. Under the lithography machine model of typical industrialized EUVL prototype production rate (Table 1), the present invention is illustrated by optimizing the structure of the M2 mirror in the system to control the deformation of the M2 mirror as an example.

[0023]

[0024]

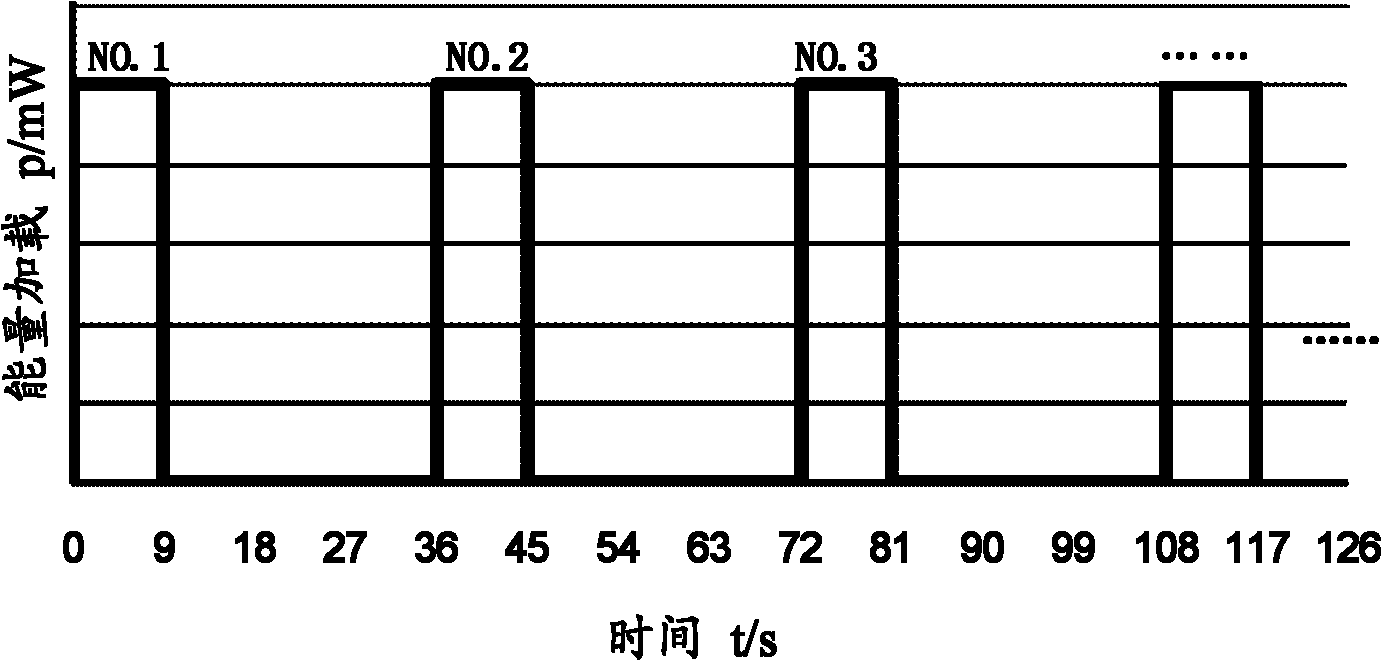

[0025] Table 1 Yield model of industrialized EUVL prototype

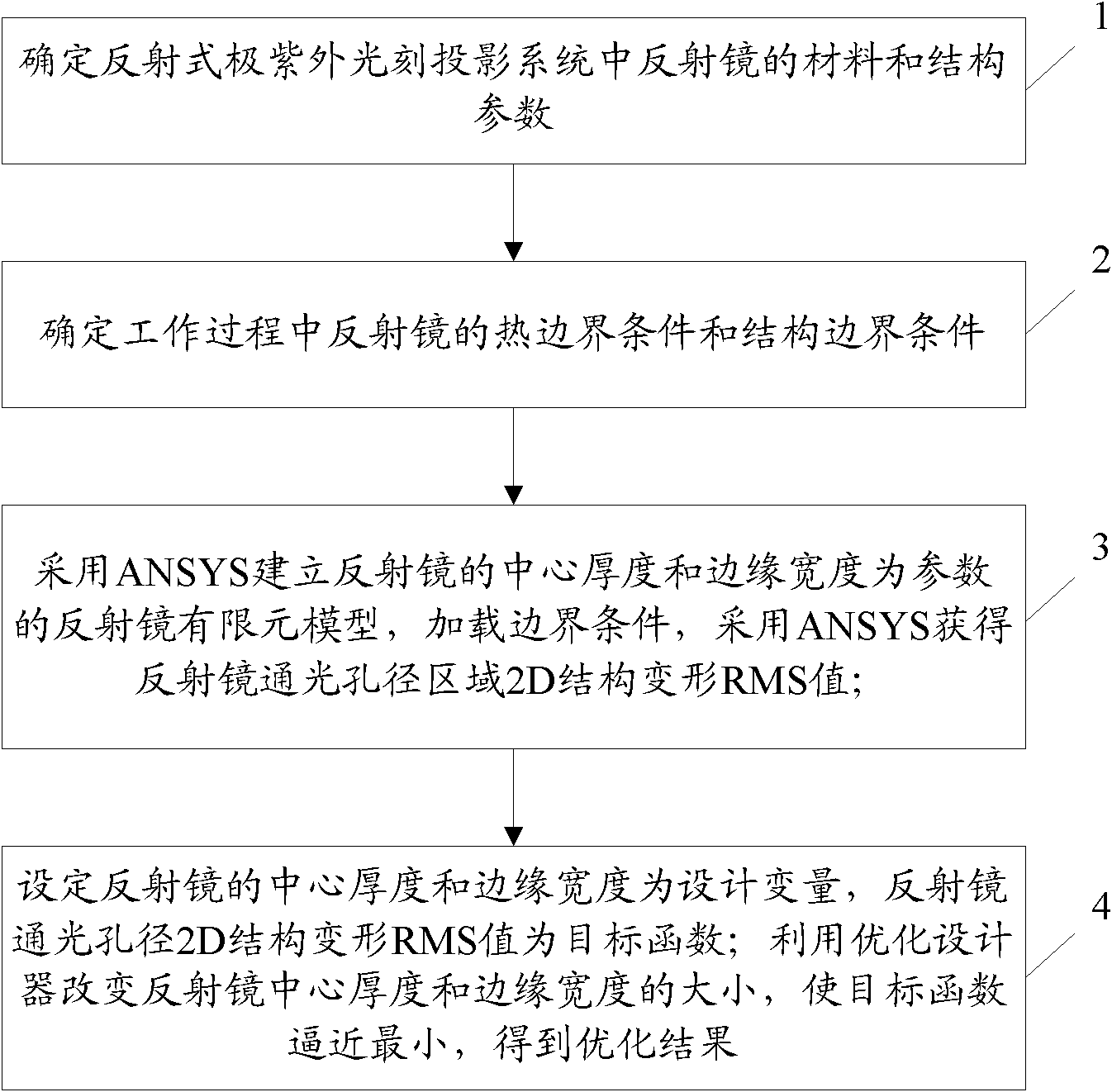

[0026] Such as figure 2 As shown, the flow chart of the projection objective lens structure optimiza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com