High-purity sulfuric acid production method without distillation procedure and device of high-purity sulfuric acid production method

A technology for sulfuric acid production without distillation, applied in chemical instruments and methods, inorganic chemistry, sulfur compounds, etc., can solve the problems of easy loss and high energy consumption of production equipment, reduce equipment use costs, reduce production energy consumption, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

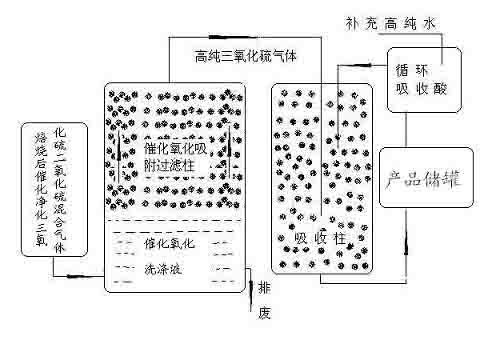

Image

Examples

Embodiment 1

[0023] The quartz glass processing column has a diameter of 8 cm and a total length of 110 cm. Among them, the conversion washing liquid column is 40cm high, and the acidic mixed catalytic oxidation solution containing high-valent chromium and high-valent manganese catalyst is injected; the oxidation adsorption filter column is 70cm high, and the porous acid-resistant material filled with manganese and vanadium oxidants. The quartz glass absorption column has a diameter of 8cm and a length of 100cm. The column is filled with porous ceramsite and quartz sand of various sizes and shapes. Introduce the aspirated air of ordinary industrial sulfuric acid into the treatment column, and after about 5 minutes, the temperature of the converted washing liquid column reaches about 65°C, open the valve of the circulating acid absorption, and absorb the purified sulfur trioxide gas with 98% high-purity parent acid, absorb The temperature of the column is rapidly raised to 47°C, and then hi...

Embodiment 2

[0027]The quartz glass processing column has a diameter of 13cm and a total length of 120cm. Among them, the conversion washing liquid column is 45 cm high, and the acidic mixed catalytic oxidation liquid containing high-valent titanium and high-valent manganese catalyst is injected; the oxidation adsorption filter column is 75 cm high, and is filled with porous acid-resistant materials of manganese and titanium oxidants. The quartz glass absorption column has a diameter of 10cm and a length of 140cm. The column is filled with porous ceramsite, quartz sand and 0.8-1cm long small quartz broken tubes of different sizes and shapes. Introduce an aspirated air from common industrial sulfuric acid into the treatment column, and after about 6 minutes, the temperature of the converted washing liquid column reaches about 63°C, open the valve of the circulating acid absorption, and absorb the purified sulfur trioxide gas with 98% high-purity parent acid, absorb The temperature of the co...

Embodiment 3

[0031] The quartz glass processing column has a diameter of 15cm and a total length of 80cm. Among them, the conversion washing liquid column is 30cm high, and the acidic mixed catalytic oxidation solution containing high-valent titanium, high-valent chromium and high-valent manganese is injected; the oxidation adsorption filter column is 50cm high, and the porous acid-resistant material filled with manganese, titanium and vanadium oxidants . The quartz glass absorption column has a diameter of 12cm and a length of 80cm. The column is filled with porous ceramsite and quartz sand of various sizes and shapes. Introduce the aspirated air of ordinary industrial sulfuric acid into the treatment column, and after about 6 minutes, the temperature of the converted washing liquid column reaches about 61°C, open the valve of the circulating acid absorption, and absorb the purified sulfur trioxide gas with 98% high-purity parent acid, absorb The temperature of the column is rapidly rais...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com