Preparation method for zirconium molybdate ultra-thin nanosheets controlled by structure-directing agent

A technology of structure-directing agent and nanosheet, which is applied in the direction of nanotechnology, chemical instruments and methods, molybdenum compounds, etc., can solve the problems that restrict the vigorous development of functional materials, fast nucleation, and difficult to guide the growth direction, and achieve the phenomenon of temperature hysteresis , Simple preparation process, adjustable heating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

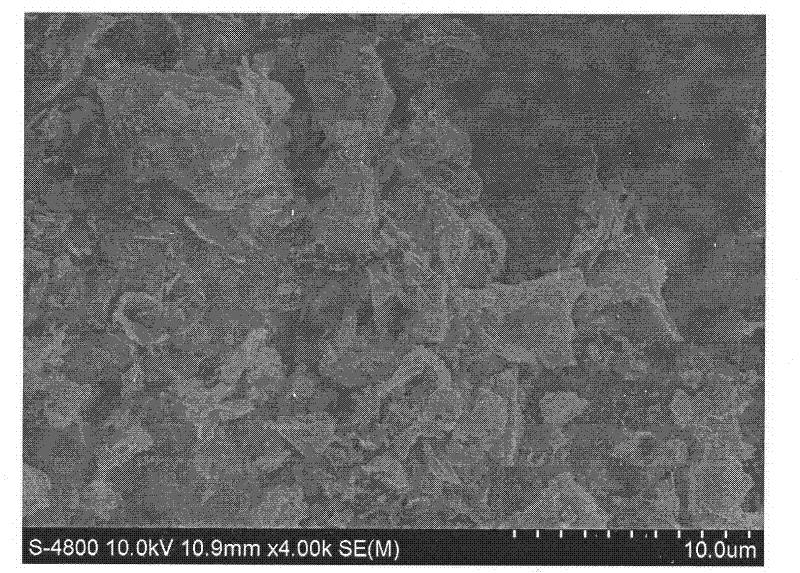

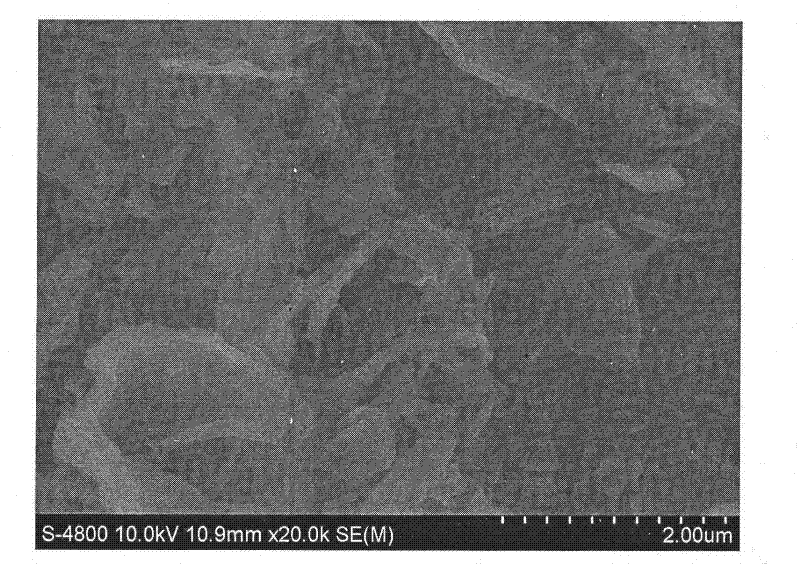

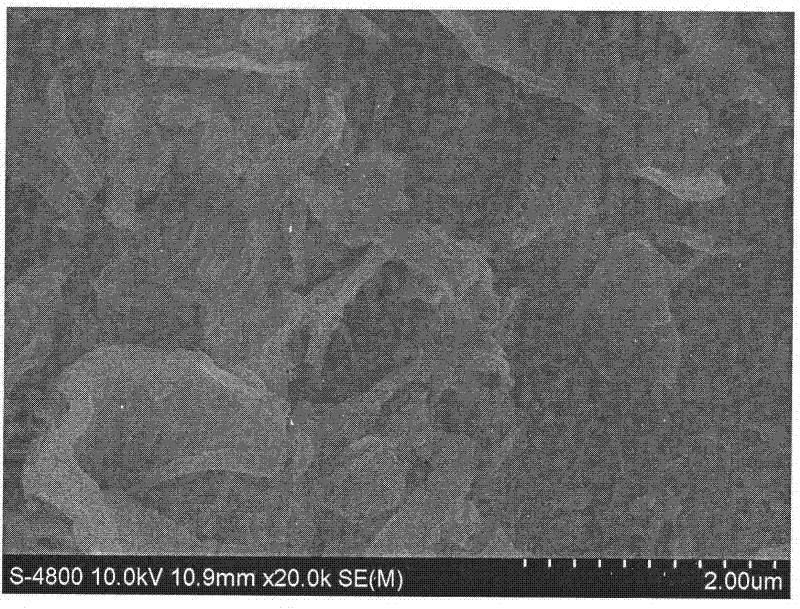

[0015] At normal temperature, configure a zirconium nitrate solution with a molar concentration of 0.01 mol / L, and then add polyethylene glycol with a molar concentration of 0.001 mol / liter in this solution; weigh (NH 4 ) 6 Mo 7 o 24 4H 2 O ammonium molybdate solid powder, add distilled water at 60-75°C, and stir vigorously to make the molar concentration 0.0014 mol / liter; slowly add the homogeneous solution prepared after stirring into the zirconium nitrate solution, and continue vigorously stirring at a constant temperature of 60°C for 15 minutes ; The transparent solution b obtained is poured into a glass reactor, and placed in an atmospheric pressure microwave radiation reactor for continuous heating for 30 minutes, and the prepared material after the reaction is Zr(MoO 4 ) 2 Zirconium molybdate ultrathin nanosheet material. Tested by product SEM ( figure 1 ) shows that the main morphology is ultra-thin nanosheets with uniform thickness and sharp edges and corners, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com