Preparation method of polyacrylic-acid modified water-soluble ferrite nano-cluster

A polyacrylic acid and nanocluster technology, applied in chemical instruments and methods, magnetic materials, magnetic objects, etc., can solve the problems of poor stability of nanoparticles, complicated preparation process, harsh operating conditions, etc., saving preparation time, convenient and rich. Set, high-yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Add 0.15mol·L -1 Polyacrylic acid (molecular weight: 1000-120,000), 0.1mol·L -1 FeCl 3 ·6H 2 O, 1mol L -1 NaAc and 0.3mol L -1 NaOH was sequentially added to 35ml of ethylene glycol, and stirred at room temperature until a uniform suspension was formed;

[0033] 2) Transfer the obtained suspension to a 50ml automatic pressure-relieving stainless steel high-pressure digestion tank (Binhai County Zhenghong Plastic Factory, model: 50ml) with a polytetrafluoroethylene liner, react at 200°C for 24h, and naturally cool to room temperature ;

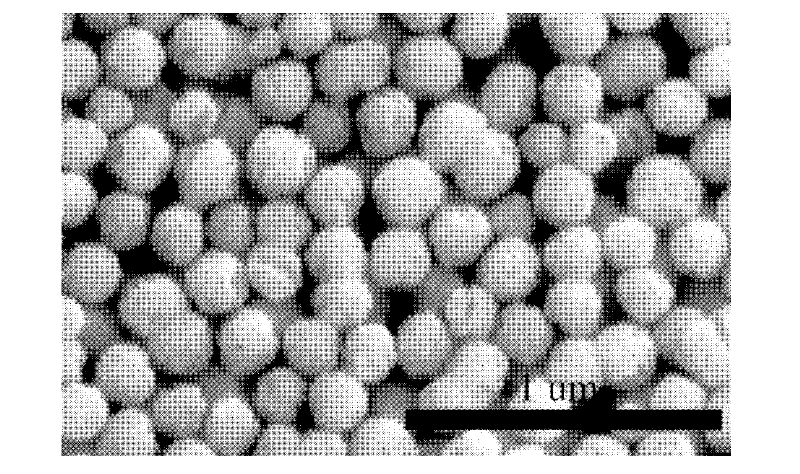

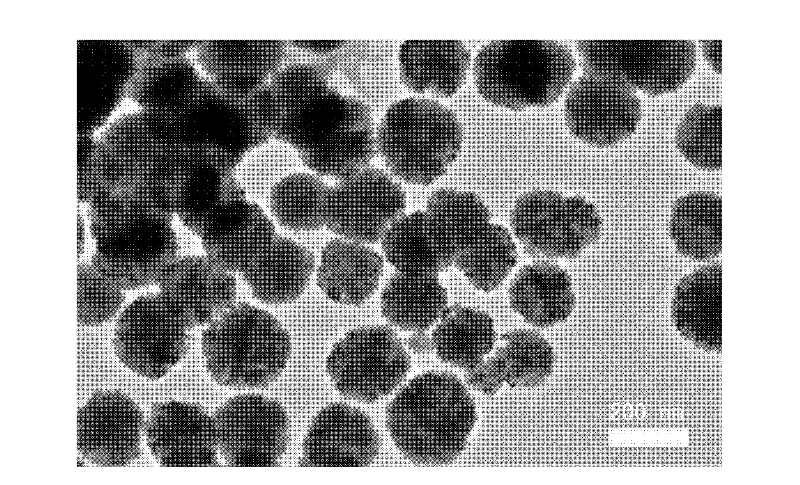

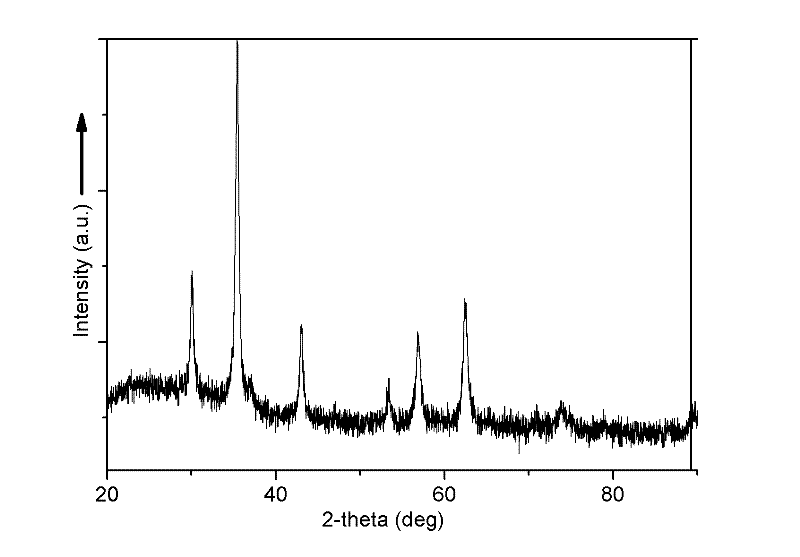

[0034] 3) The obtained black solid is magnetically separated under the action of an external magnetic field, and the sample is cleaned under ultrasonic conditions with a mixed solution of ethanol and water, so that the magnetic separation-ultrasonic cleaning is performed 3 to 5 times; the obtained solid is dispersed in 5ml of water, and the size is 182.1nm polyacrylic acid-modified Fe 3 o 4 Stable aqueous solutions of nanoclus...

Embodiment 2

[0041] Example 1 was repeated, the only difference being that no NaOH was added, the reaction temperature was 220° C., and the reaction time was 12 h. The resulting polyacrylic acid-modified water-soluble Fe 3 o 4 The average size of the nanoclusters is 97.7 nm.

Embodiment 3

[0043] Repeat Example 2, the only difference is that the amount of NaAc is 2mol L -1 . The resulting polyacrylic acid-modified water-soluble Fe 3 o 4 The average size of the nanoclusters is 52.7 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com