EIA (Environmental Impact Assessment) ecological environment-friendly type inorganic active building heat-insulating mortar

An environmentally friendly technology for building thermal insulation mortar, applied in the field of building materials, can solve the problems of poor fireproof performance of EPS thermal insulation mortar, unable to meet the requirements of thermal insulation and energy saving, poor anti-aging and weather resistance, etc., so as to shorten the construction period, save maintenance funds, and reduce construction costs. The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 (for reference only)

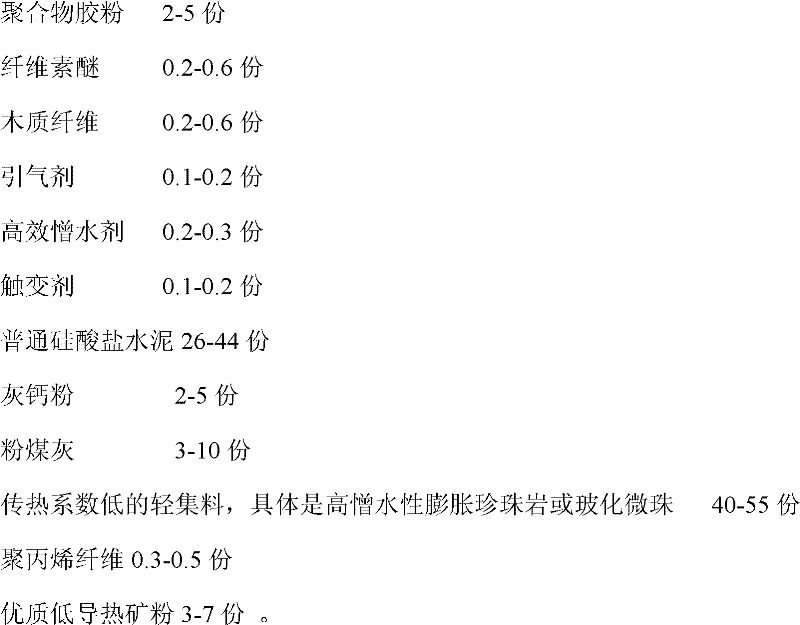

[0023] Taking the northern city (Tianjin City) as an example, the composition and mass parts of each component of EIA inorganic active building thermal insulation mortar are:

[0024]

[0025] Each serving can be 1kg.

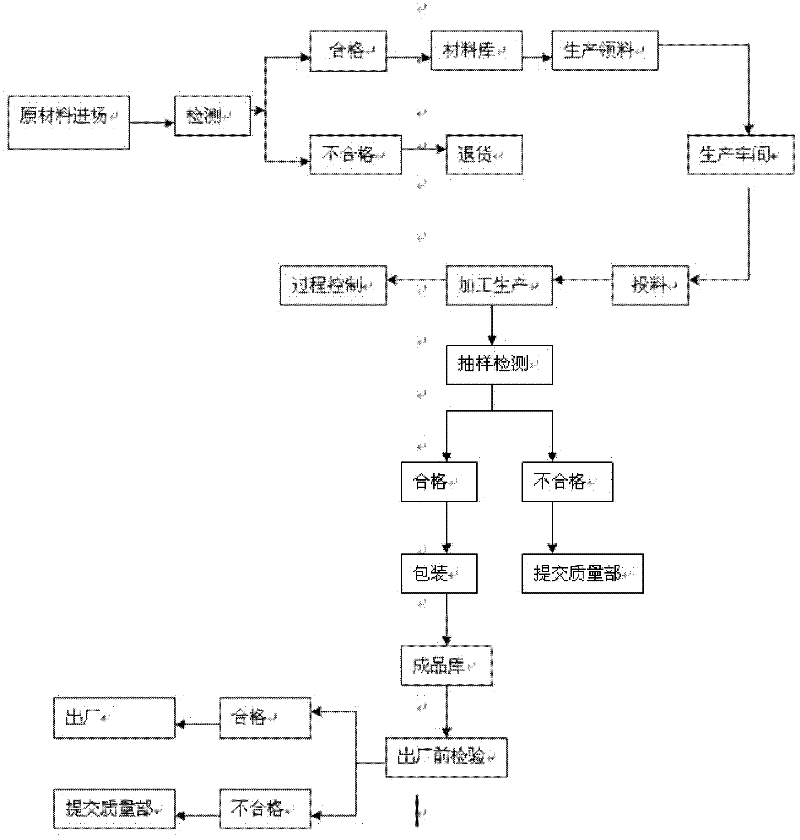

[0026] The manufacture craft of described EIA inorganic active building insulation mortar is as follows figure 1 shown.

Embodiment 2

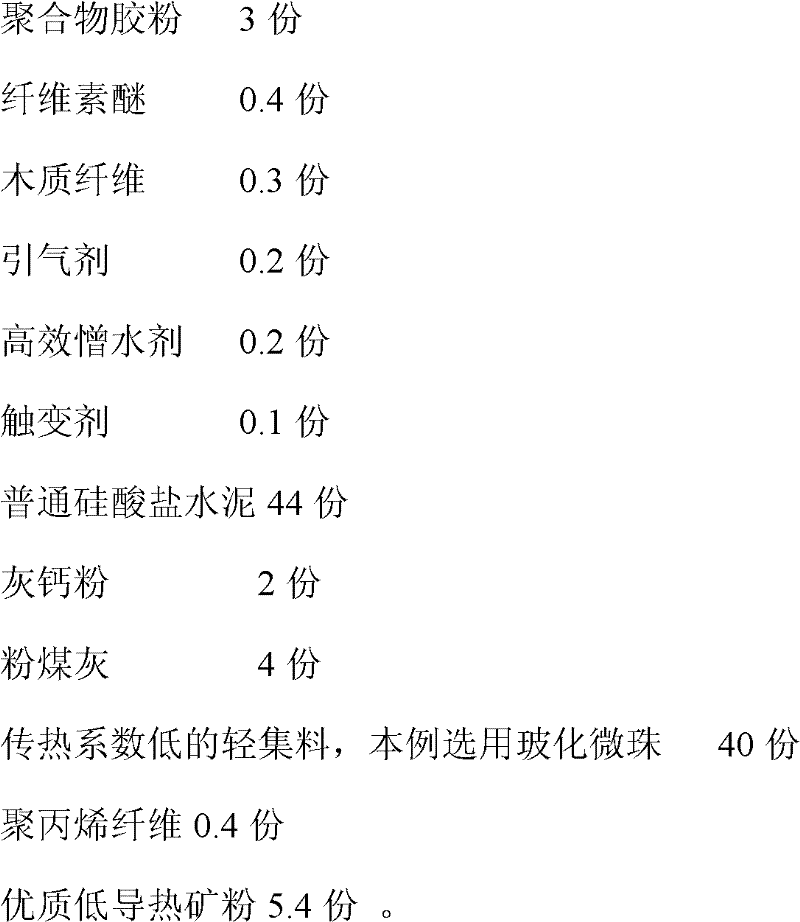

[0028] Taking the southern region as an example, the composition and mass parts of each component of EIA inorganic active building thermal insulation mortar are:

[0029]

[0030]

[0031] Each serving can be 1kg.

[0032] The manufacture craft of described EIA inorganic active building insulation mortar is as follows figure 1 shown.

example 3

[0034] Taking Xinjiang city as an example, the composition of EIA inorganic active building insulation mortar and the mass parts of each component are:

[0035]

[0036] Each serving can be 1kg.

[0037] The manufacture craft of described EIA inorganic active building insulation mortar is as follows figure 1 shown.

[0038] The inorganic active building thermal insulation mortar of the present invention has been tested, and its fireproof performance index is shown in Table 1 and Table 2.

[0039] Table 1

[0040]

[0041] Table 2

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com