Preparation method of red mud iron reduction furnace slag light foamed ceramic and iron reduction furnace

A technology of lightweight foam and reduction furnace, applied in ceramic products, improvement of process efficiency, application, etc., can solve problems such as waste, low added value, serious environmental pollution, etc., to reduce production costs, save energy, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

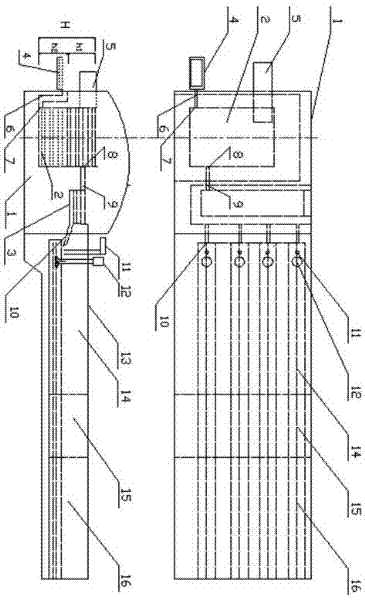

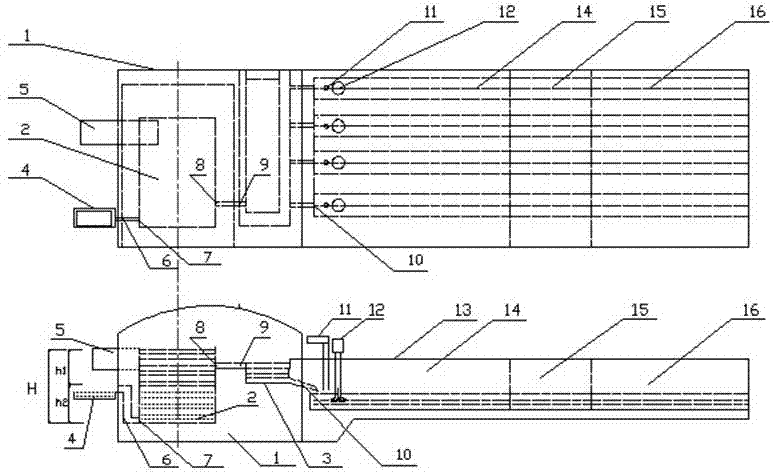

Image

Examples

Embodiment 1

[0024] (1) Ingredients: 35% of red mud, 15% of raw coke gemstones, 10% of waste glass powder, 15% of quartz sand, 20% of coal gangue, 5% of titanium dioxide, and mix them evenly to make a mixture. Among them, the iron of red mud The content is 8%;

[0025] (2) Preparation of foaming agent: magnesium carbonate, water glass and waste glass powder are uniformly mixed at a weight ratio of 60:20:20, dried and fired at 700°C for 1 hour, and then ground to a fine particle size of 10 μm;

[0026] (3) Smelting reduction: The above-mentioned mixture plus 1% coal powder is fully mixed and fully reduced in a reducing atmosphere at a temperature of 1200°C, and then the briquettes are put into the molten pool 2 in the iron reduction furnace 1 through the feeder 5, The temperature is 1550°C, the atmosphere is an oxidizing atmosphere, and the briquette sinks below the liquid level of the slag melt and melts. The height h2 of the bottom is used to control the feeding speed of the feeder 5, so...

Embodiment 2

[0032] (1) Ingredients: 58% red mud, 9% raw coke gemstones, 7% waste glass powder, 8% quartz sand, 15% coal gangue, 3% titanium dioxide, and mix them evenly to make a mixture. Among them, iron in red mud The content is 24%;

[0033] (2) Preparation of foaming agent: Magnesium carbonate, calcium carbonate, water glass and waste glass powder are uniformly mixed in a weight ratio of 40:35:12:13, dried and fired at 550°C for 2 hours, and then ground to a fine particle size of Made of 15μm;

[0034] (3) Smelting reduction: The above-mentioned mixture plus 3% coal powder is fully mixed and fully reduced in a reducing atmosphere at a temperature of 1100°C, and then put into the molten pool 2 in the iron reduction furnace 1 through the feeder 5 briquetting, The temperature is 1600°C, the atmosphere is an oxidizing atmosphere, and the briquette sinks below the liquid level of the slag melt and melts. The height h2 of the bottom is used to control the feeding speed of the feeder 5, so...

Embodiment 3

[0040] (1) Ingredients: 82.5% red mud, 3% raw coke gemstones, 3% waste glass powder, 1% quartz sand, 10% coal gangue, 0.5% titanium dioxide, and mix them evenly to make a mixture. Among them, iron in red mud The content is 40%;

[0041] (2) Preparation of foaming agent: Calcium carbonate, calcium sulfate, magnesium carbonate, magnesium sulfate, water glass and waste glass powder are evenly mixed in a weight ratio of 20:20:20:30:5:5, and then dried and kept at 400°C Fired for 3 hours, then ground to a fine particle size of 20 μm;

[0042] (3) Smelting reduction: the above mixture plus 5% coal powder is fully mixed and fully reduced in a reducing atmosphere at a temperature of 1200 ° C, and then put into the molten pool 2 in the iron reduction furnace 1 through the feeding machine 5 briquetting , the temperature is 1650 ° C, the atmosphere is an oxidizing atmosphere, the briquette sinks below the liquid level of the slag melt and melts, and the distance between the upper surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com