Branch-shaped damping agent and preparation method and use thereof

A dendritic and damping agent technology, applied in the field of damping materials, can solve the problems of high cost, low energy conversion efficiency, difficult to use in a large area, etc., and achieves excellent mechanical properties and wear resistance, low preparation cost, and good damping effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

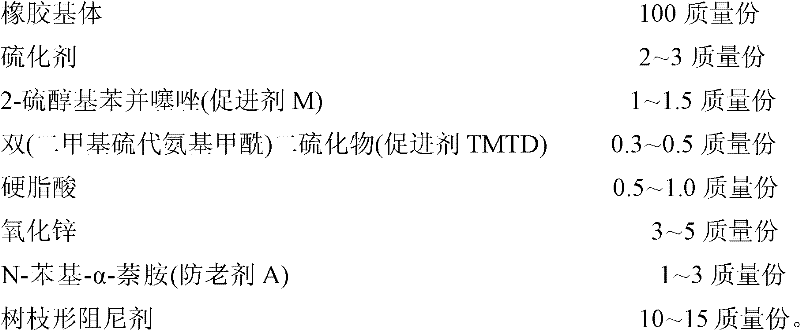

Method used

Image

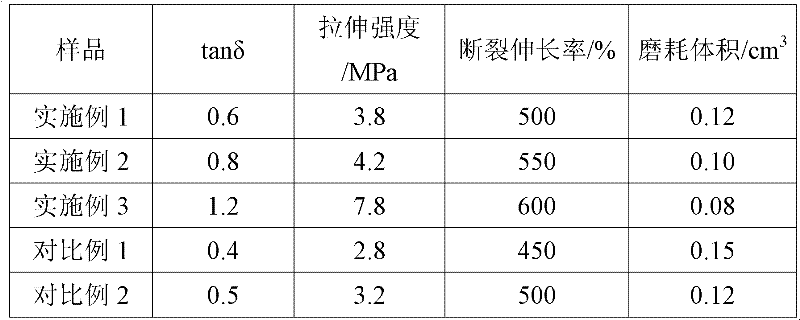

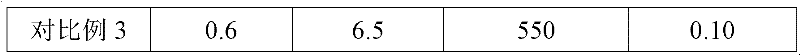

Examples

Embodiment 1

[0041] a) 25g of inorganic montmorillonite and 25mL of methyltrichlorosilane were added to a three-necked flask, and 50mL of 40% ethanol aqueous solution was added, heated to 70°C, stirred and reacted for 3 hours, and then solid-liquid separation was carried out. The separated solid was washed, and then vacuum-dried at 70°C to obtain organic montmorillonite;

[0042] b) Add 0.10mol octamethylcyclotetrasiloxane, 0.20mol methylhydrogendichlorosilane and 10mL acetic acid into a four-necked flask, 2 In some cases, after stirring for 20 minutes, the temperature was raised to 40°C for 5 hours, and then dehydrated for 10 minutes to obtain a colorless and transparent liquid, that is, 11-hydropermethyl-1-hexasiloxanol;

[0043] c) Add 0.20mol 11-hydropermethyl-1-hexasiloxanol, 0.10mol trimethylchlorosilane and 10mL pyridine into a four-necked flask, 2 In some cases, after stirring for 40 minutes, the temperature was raised to 60°C for 4 hours to obtain a colorless transparent liquid, ...

Embodiment 2

[0050] a) 60g of inorganic montmorillonite and 33mL of methyltrichlorosilane were added to a three-necked flask, and 60mL of ethanol aqueous solution with a volume concentration of 50% was added, heated to 80°C, stirred for 2.5 hours, and then solid-liquid separation was carried out. The separated solid was washed, and then vacuum-dried at 80°C to obtain organic montmorillonite;

[0051] b) Add 0.20mol octamethylcyclotetrasiloxane, 0.30mol methylhydrogendichlorosilane and 15mL acetic acid into a four-necked flask, 2 In some cases, after stirring for 30 minutes, the temperature was raised to 50°C for 4 hours, and then dehydrated for 15 minutes to obtain a colorless transparent liquid, that is, 11-hydropermethyl-1-hexasiloxanol;

[0052] c) Add 0.30mol 11-hydropermethyl-1-hexasiloxanol, 0.15mol trimethylchlorosilane and 15mL pyridine into a four-necked flask, 2 In some cases, after stirring for 50 minutes, the temperature was raised to 70°C for 3 hours to obtain a colorless tra...

Embodiment 3

[0059] a) 105g of inorganic montmorillonite and 42mL of dimethyldichlorosilane were added to a three-necked flask, and 70mL of an aqueous ethanol solution with a volume concentration of 60% was added, heated to 90°C, stirred and reacted for 2 hours, and then solid-liquid separation was performed, Wash the separated solid, and then dry it in vacuum at 90°C to obtain organic montmorillonite;

[0060] b) Add 0.30mol octamethylcyclotetrasiloxane, 0.40mol methylhydrogendichlorosilane and 20mL acetic acid into a four-necked flask, 2 In some cases, after stirring for 40 minutes, the temperature was raised to 60°C for 3 hours, and then dehydrated for 20 minutes to obtain a colorless and transparent liquid, that is, 11-hydropermethyl-1-hexasiloxanol;

[0061] c) Add 0.40mol 11-hydropermethyl-1-hexasiloxanol, 0.20mol trimethylchlorosilane and 20mL pyridine into a four-necked flask, 2 In some cases, after stirring for 60 minutes, the temperature was raised to 60°C for 2 hours to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com