Chitosan composite preservative film and preparation process thereof

A composite fresh-keeping and chitosan technology, which is applied in the field of plastic film, can solve the problems of poor fresh-keeping effect and difficult degradation of PE fresh-keeping film, and achieve the effects of good biocompatibility, strong practicability and good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

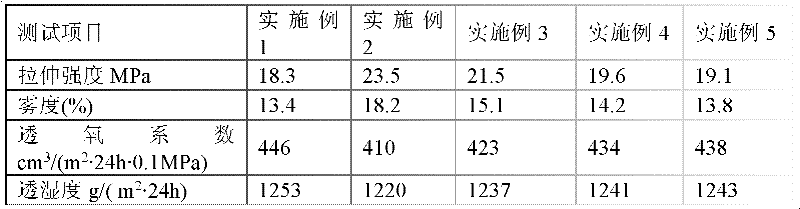

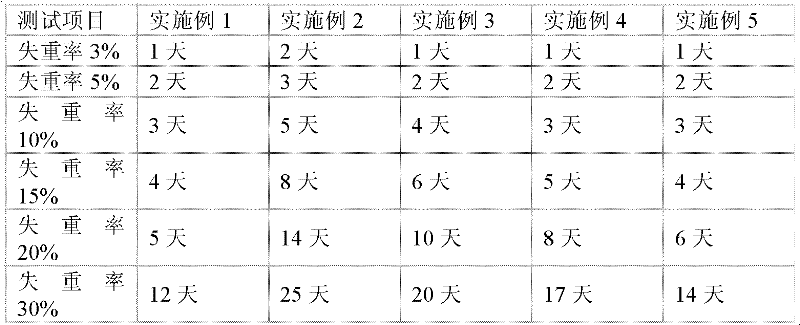

Embodiment 1

[0026] The components and weight components of the preservative film A are: 100 parts of chitosan, 3000 parts of 1% acetic acid solution, 1 part of sodium trimetaphosphate, 30 parts of silica sol, 100 parts of glycerin and 2 parts of oleic acid.

Embodiment 2

[0028] The components and weight components of the preservative film B are: 100 parts of chitosan, 4000 parts of 1% acetic acid solution, 5 parts of sodium trimetaphosphate, 50 parts of silica sol, 200 parts of glycerin and 10 parts of oleic acid.

Embodiment 3

[0030] The components and weight components of the preservative film C are: 100 parts of chitosan, 3000 parts of 1% acetic acid solution, 3 parts of sodium trimetaphosphate, 50 parts of silica sol, 200 parts of glycerin and 4 parts of oleic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com