Sound insulation material

The technology of a composition and hollow microbeads is applied in the field of compositions for sound insulation and vibration isolation in the automotive interior decoration industry. The effect of high elongation at break and simple technical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

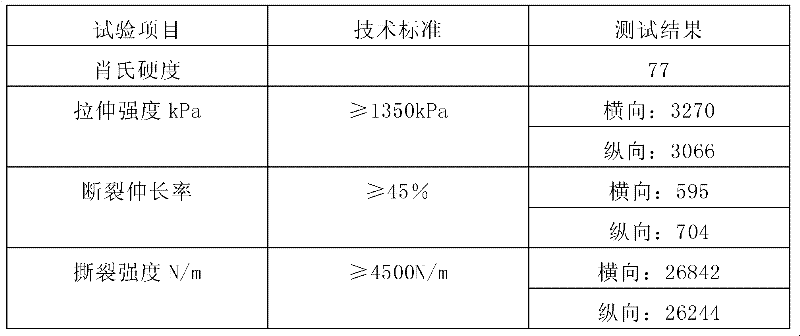

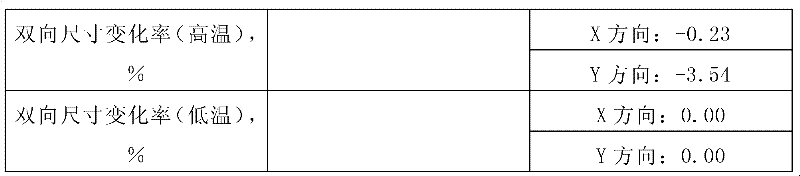

[0066]LLDPE produced by China Petroleum Jilin Petrochemical Company, grade (7042) 4Kg, EVA produced by Sinopec Yangzi BASF Co., Ltd., grade (V51105) 6Kg, POE3Kg produced by Exxon Corporation of the United States, EPDM produced by Dow Corporation of the United States, grade (4725) 4Kg, hollow microspheres produced by Shanghai Zhengmeiya Nano Ultrafine Material Manufacturing Co., Ltd., grade 800 mesh (≤20um vacuum degree is 1.8-2.5 bulk density 0.9-1.2), 35Kg, produced by Jiangsu Yiteng Chemical Co., Ltd. 0.25Kg of carbon black, 0.25Kg of white oil produced by Shanghai Haidi Lubricating Oil Co., Ltd., 0.30Kg of zinc stearate produced by Shanghai Jieyu Industry and Trade Co., Ltd., 0.4kg of coupling agent produced by Yangzhou Lida Resin Co., Ltd., mixed After uniformity, use the parallel twin-screw extruder TSK-65 / 36 produced by Jiangsu Zhangjiagang Bell Machinery Co., Ltd. to granulate, and then use the extruder SJ / 120 / 38 produced by Zhangjiagang Wanteng Machinery Co., Ltd. to ob...

Embodiment 2

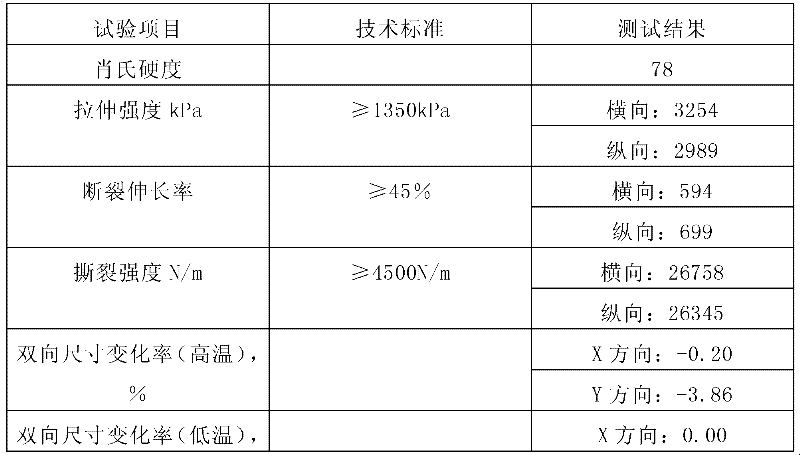

[0071] The LLDPE brand (7042) 4KG produced by the petrochemical plant of PetroChina Lanzhou Company, the EVA brand (7A50H) 6KG produced by China Taiwan Formosa Plastics Co., Ltd., the POE (107) 3KG produced by Korea LG Chemical Co., Ltd., and the Japanese Mitsui Chemicals Company EPDM (4045) 4KG, Shanghai Zhengmei Nano Ultrafine Material Manufacturing Co., Ltd.’s hollow microbeads grade 1250 mesh (≤20um vacuum degree is 1.8-2.5 bulk density 0.9-1.2), 35KG, produced by Jiangsu Yancheng Xinlihua Plastic Co., Ltd. Black masterbatch grade (E701) 0.25KG, white oil produced by Shanghai Hairun Huayou Co., Ltd. 0.25KG, PALMERA produced by Tyko Palm Chemical (Zhangjiagang) Co., Ltd. 0.35KG, titanium produced by Nanjing Shuguang Chemical Ester 0.4KG, after mixing evenly, use the parallel twin-screw extruder TSK-65 / 36 produced by Jiangsu Zhangjiagang Bell Machinery Co., Ltd. to granulate, and then use the extruder SJ / 120 / 38 produced by Zhangjiagang Wanteng Machinery Co., Ltd. damping sou...

Embodiment 3

[0076] LDPE 4KG produced by Shanghai Petrochemical General Plant Plastic Factory, EVA grade (VA900) 6KG produced by Hanwha Corporation of South Korea, POE grade (8150) 3KG produced by Dow Chemical Company of the United States, EPDM 4KG produced by Lanzhou Petrochemical Company Synthetic Rubber Factory, Shanghai The hollow microbeads produced by Zhengmei Nano Ultrafine Material Manufacturing Co., Ltd. are 2500 mesh ≤ 20um and the vacuum degree is 1.8-2.5. Lubricating Oil Co., Ltd. produces 0.25KG of white oil, Guangdong Hanwei New Material Technology Co., Ltd. produces 0.35KG of stearic acid, and Yangzhou Lida Resin Co., Ltd. produces 0.4KG of coupling agent. After mixing evenly, use Jiangsu Zhangjiagang Bell Machinery Co., Ltd. The parallel twin-screw extruder TSK-65 / 36 produced by the company is used for granulation, and then the extruder SJ / 120 / 38 produced by Zhangjiagang Wanteng Machinery Co., Ltd. is used to make the damping sound insulation board.

[0077] The damping and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com