Low-smoke halogen-free flame-retarding polypropylene cable material and preparation method thereof

A flame retardant polypropylene and cable material technology, applied in the field of cable materials, can solve the problems of reducing the temperature resistance level of the material, reducing the mechanical properties of the material, the stress cracking resistance of the processing performance, etc., and achieving reduced corrosion, good appearance, and rheological properties. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

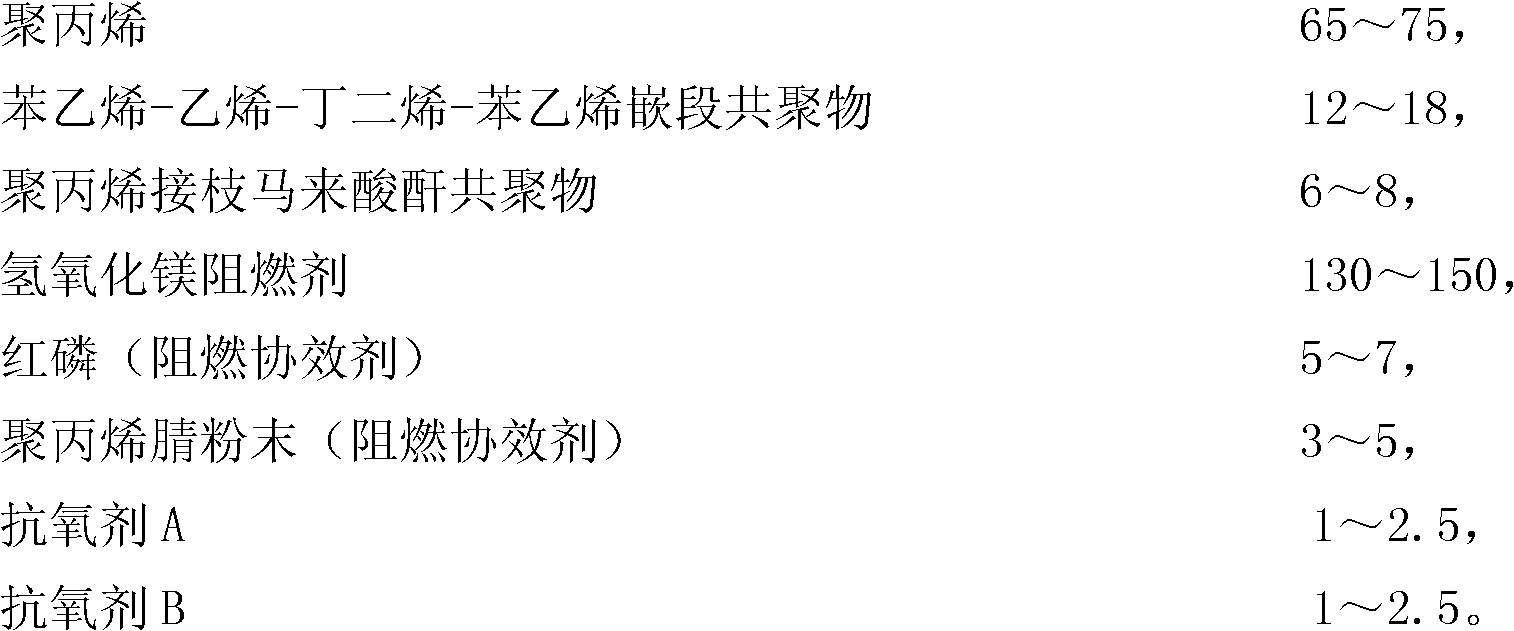

[0023] A low-smoke halogen-free flame-retardant polypropylene cable material, which is composed of polypropylene, styrene-ethylene-butadiene-styrene block copolymer, polypropylene grafted maleic anhydride copolymer, magnesium hydroxide flame retardant , red phosphorus (flame retardant synergist), polyacrylonitrile powder (flame retardant synergist), antioxidant A and antioxidant B raw materials are prepared, and the parts by weight of each raw material are:

[0024]

[0025]

[0026] Described magnesium hydroxide flame retardant is stearic acid modified magnesium hydroxide flame retardant (ie stearic acid modified magnesium hydroxide flame retardant, is existing product).

[0027] The antioxidant A is selected from tris[2.4-di-tert-butylphenyl]phosphite.

[0028] The antioxidant B is selected from tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythyl ester.

[0029] The red phosphorus is red phosphorus with a particle diameter of 5-10 um microencapsulate...

Embodiment 2

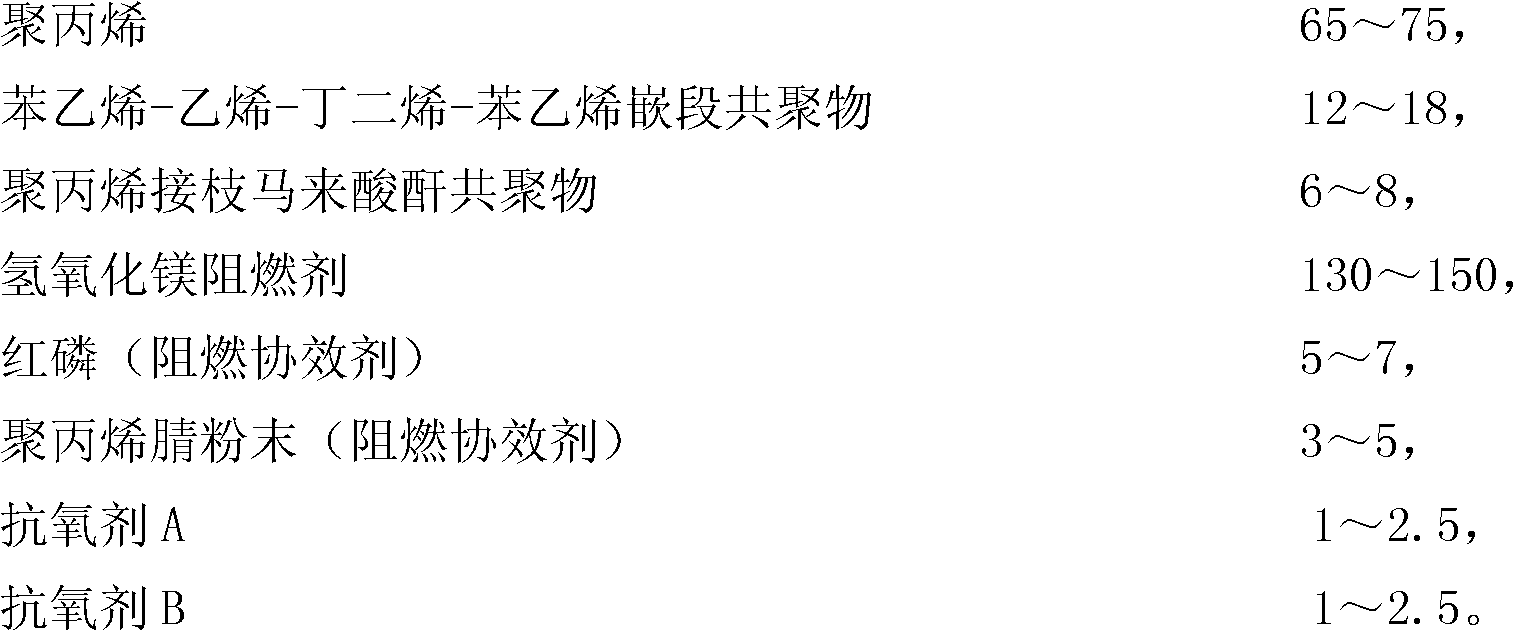

[0038] A low-smoke halogen-free flame-retardant polypropylene cable material, which is composed of polypropylene, styrene-ethylene-butadiene-styrene block copolymer, polypropylene grafted maleic anhydride copolymer, magnesium hydroxide flame retardant , red phosphorus (flame retardant synergist), polyacrylonitrile powder (flame retardant synergist), antioxidant A and antioxidant B raw materials are prepared, and the parts by weight of each raw material are:

[0039]

[0040]

[0041] Described magnesium hydroxide flame retardant is stearic acid modified magnesium hydroxide flame retardant (ie stearic acid modified magnesium hydroxide flame retardant, is existing product).

[0042] The antioxidant A is selected from bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphate.

[0043] The antioxidant B is selected from stearyl β(3,5-di-tert-butyl-4-hydroxyphenyl)propionate.

[0044] The red phosphorus is red phosphorus with a particle diameter of 5-10 um microencapsulated b...

Embodiment 3

[0053]A low-smoke halogen-free flame-retardant polypropylene cable material, which is composed of polypropylene, styrene-ethylene-butadiene-styrene block copolymer, polypropylene grafted maleic anhydride copolymer, magnesium hydroxide flame retardant , red phosphorus (flame retardant synergist), polyacrylonitrile powder (flame retardant synergist), antioxidant A and antioxidant B raw materials are prepared, and the parts by weight of each raw material are:

[0054]

[0055] Described magnesium hydroxide flame retardant is stearic acid modified magnesium hydroxide flame retardant (ie stearic acid modified magnesium hydroxide flame retardant, is existing product).

[0056] The antioxidant A is selected from tris[2.4-di-tert-butylphenyl]phosphite.

[0057] The antioxidant B is selected from tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythyl ester.

[0058] The red phosphorus is red phosphorus with a particle diameter of 5-10 um microencapsulated by melamine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com