High-density fire-proof silicone rubber and preparation method thereof

A silicone rubber and high-density technology, which is applied in the field of high-density fire-resistant silicone rubber and its preparation, can solve the inconvenience of maintenance and replacement of pipes and cables and other wall-penetrating objects, and cannot adapt to workplaces with high fire-proof requirements. To meet the radiation resistance requirements of nuclear power plants and other issues, achieve the effects of easy disassembly and replacement, good electrical insulation, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] a) Take by weighing each raw material according to the following formula:

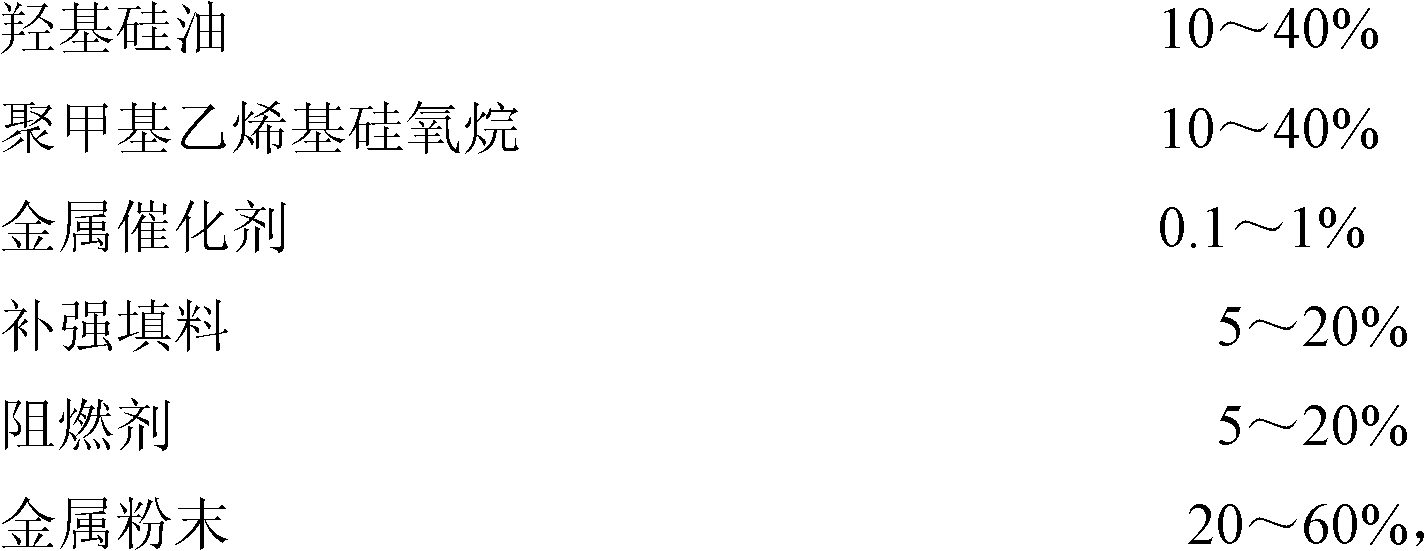

[0036] The composition formula of A component is as follows:

[0037]

[0038]

[0039] The composition formula of B component is as follows:

[0040]

[0041] b) Add polymethylvinylsiloxane and hydroxy silicone oil in component A into the reaction kettle, mix for 10 to 60 minutes at 20 to 60°C and a vacuum of -0.1 to 0.05 MPa, and then add to the above mixed solution Metal catalyst and reinforcing filler are stirred and mixed with a high-speed emulsifier for 30-60 minutes, then a flame retardant is added and stirred and mixed, metal powder is added, and vacuum degassed for 30-60 minutes; press filter with a 100-mesh filter, and fill to obtain A components;

[0042] c) Add polymethylvinylsiloxane, hydrogen-containing silicone oil, and hydroxyl silicone oil in component B into the reaction kettle, stir at 20-60°C for 10-60 minutes, and then add reinforcing filler, barrier Combustion a...

Embodiment 2

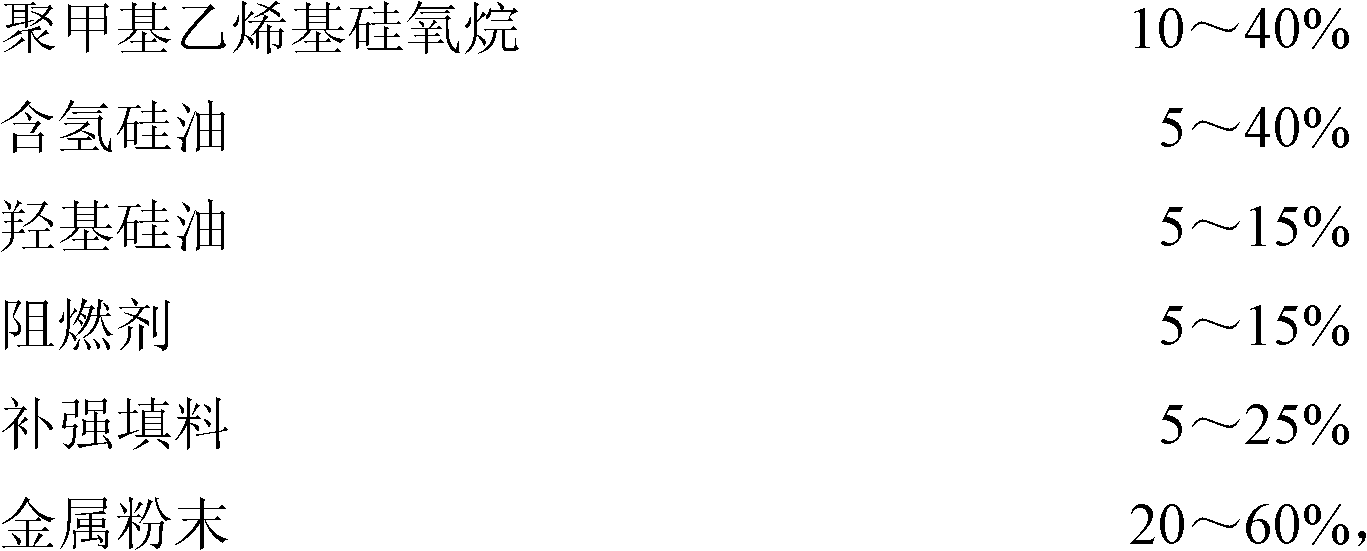

[0045] The composition formula of A component is as follows:

[0046]

[0047]

[0048] The composition formula of B component is as follows:

[0049]

[0050] All the other contents are the same as those described in Example 1.

Embodiment 3

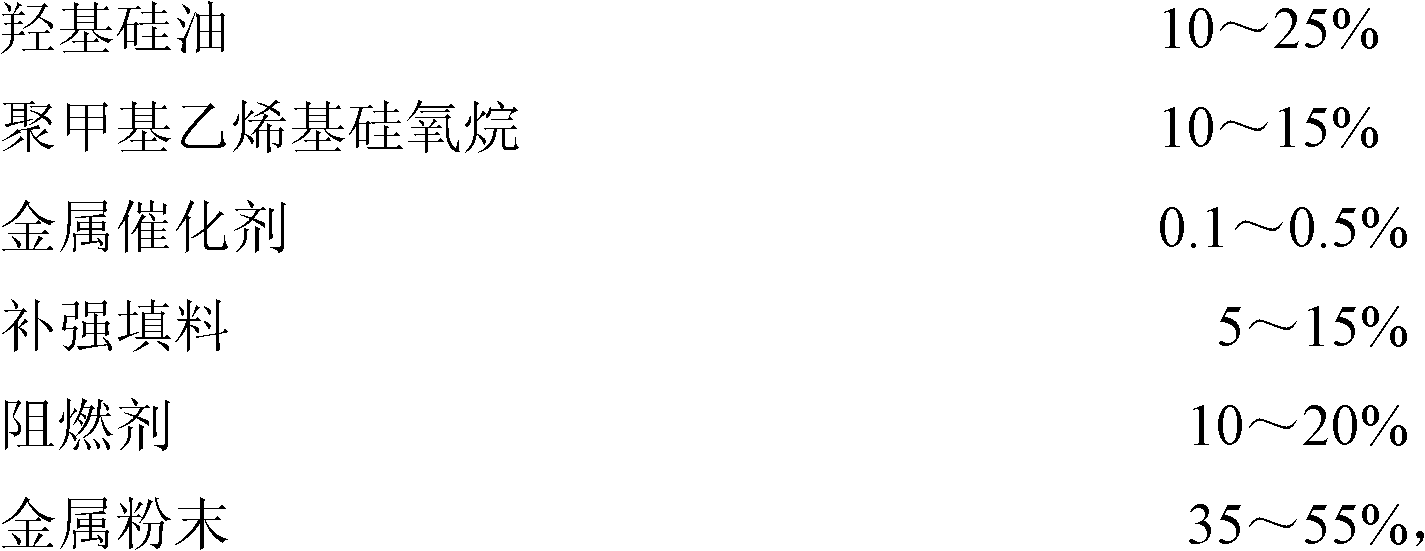

[0052] The composition formula of A component is as follows:

[0053]

[0054] The composition formula of B component is as follows:

[0055]

[0056] All the other contents are the same as those described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com