Method for recovering lost gold-loaded carbon from tailings obtained in carbon leaching gold extraction process

A gold-loaded carbon and carbon leaching technology, which is applied in the field of mineral processing engineering, can solve the problems of gold loss, wear resistance, and loss, and achieve the effects of easy production, good recovery effect, and low chemical consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

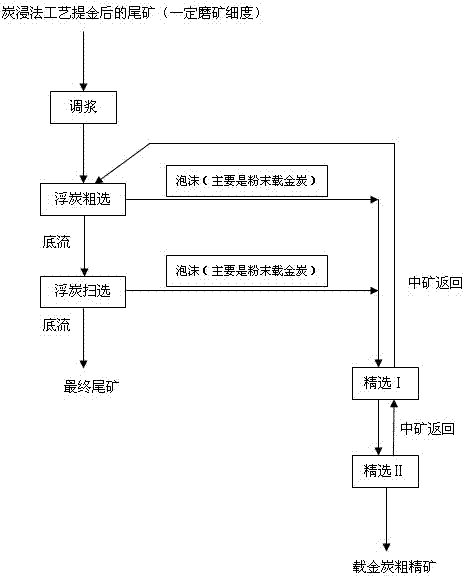

Image

Examples

Embodiment 1

[0016] The tailings of Huaniushan carbon leaching gold extraction process in Guazhou, Gansu contain 0.88% organic carbon and 0.49 g / t gold. The main minerals in the tailings are pyrrhotite and pyrite, and the gangue minerals are quartz, Fluorite, calcite and hornblende, etc. After sieving the tailings with a 100-mesh sieve to remove large particles and debris, the particle size is -200 mesh, accounting for 85%, adding water to adjust the slurry concentration to 35%, adding sodium carbonate to adjust the pH value to 8, adding kerosene 400 g / t, pine oil 50g / t, carry out rough selection of floating carbon; after rough selection of powdered gold-loaded carbon, add kerosene 100 g / t, pine oil 20g / t to carry out floating carbon sweeping; roughing and sweeping foam are combined for two second choice The foam is the gold-loaded carbon coarse concentrate, and the middle ore of the selection Ⅰ returns to the roughing, and the selection The medium ore is returned to beneficiation I f...

Embodiment 2

[0018] The tailings of the carbon leaching gold extraction process in Yantai Gold Smelter, Shandong Province contain 0.97% organic carbon and 0.65 g / t gold. The main minerals in the tailings are pyrrhotite and arsenopyrite, and the gangue minerals are Quartz, calcite, etc. Screen the tailings with a 100-mesh sieve to remove large particles and debris. The particle size is -200 mesh, accounting for 93%. Add water to adjust the slurry concentration to 30%, add sodium carbonate to adjust the pH value to 7.5, and add kerosene 300 g / t , pine oil 30g / t, carry out floating carbon roughing; after roughing out gold-loaded carbon, add kerosene 200 g / t, pine oil 25g / t into the slurry to carry out floating carbon sweeping; roughing and sweeping foam are combined for two second choice The foam is the gold-loaded carbon coarse concentrate, and the middle ore of the selection Ⅰ returns to the roughing, and the selection The medium ore is returned to beneficiation I for recycling treatmen...

Embodiment 3

[0020] The tailings of Ulaga Gold Mine in Heilongjiang contain 1.52% organic carbon and 6.0 g / t gold in the carbon leaching gold extraction process. The main metal minerals in the tailings are pyrite, and the gangue minerals are mica, quartz and some mud. quality minerals. After sieving the tailings with a 100-mesh sieve to remove large particles and debris, the particle size is -200 mesh, accounting for 95%, adding water to adjust the slurry concentration to 40%, adding sodium carbonate to adjust the pH value to 8, adding kerosene 600 g / t, pine oil 40g / t, carry out rough selection of floating carbon; after coarse selection of powdered gold-loaded carbon, add 300 g / t of kerosene and 30 g / t of pine oil to carry out floating carbon sweeping; roughing and sweeping foam are combined and carried out two picks, picks The foam is the gold-loaded carbon coarse concentrate, and the middle ore of the selection Ⅰ returns to the roughing, and the selection The middle ore in the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com