Hierarchical porosity carbon fiber material, preparation method and application thereof

A carbon fiber and hierarchical hole technology, applied in the field of materials, can solve the problems of low utilization level of sisal fiber and low added value, and achieve the effects of high output and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The steps of preparing hierarchical porous carbon fiber material with sisal fiber as raw material are as follows:

[0032](1) Wash the sisal fibers, cut them to a length of 0.1-0.5 cm for each fiber, and then place them in an oven to dry at 100°C for 6 hours.

[0033] (2) placing the pretreated sisal fiber in step (1) in a carbonization furnace, under a nitrogen atmosphere with a flow rate of 400ml / min, heat up to 500°C with a heating rate of 5°C / min, and then carbonize at a constant temperature After 3 hours, the layered porous carbon fiber material was obtained.

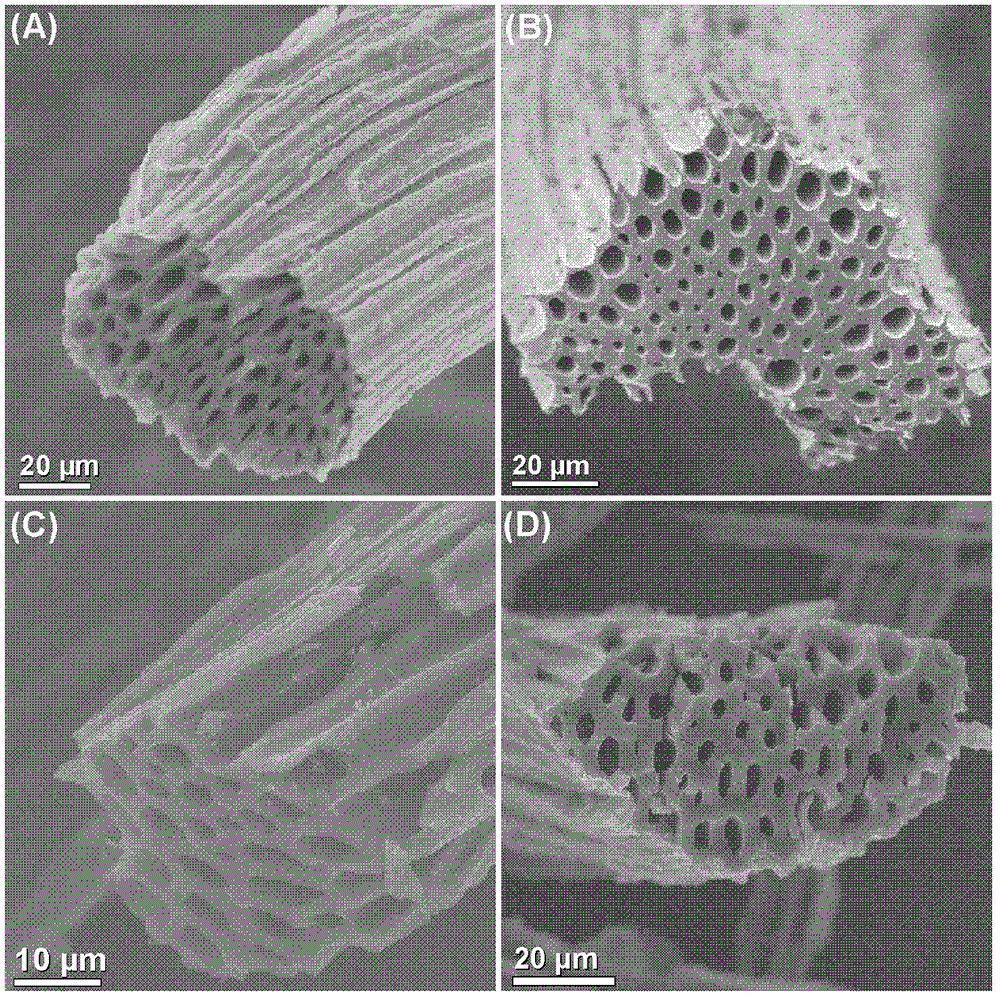

[0034] The scanning electron microscope of the hierarchical porous carbon fiber material prepared by the above steps is as follows: figure 1 shown in A and B.

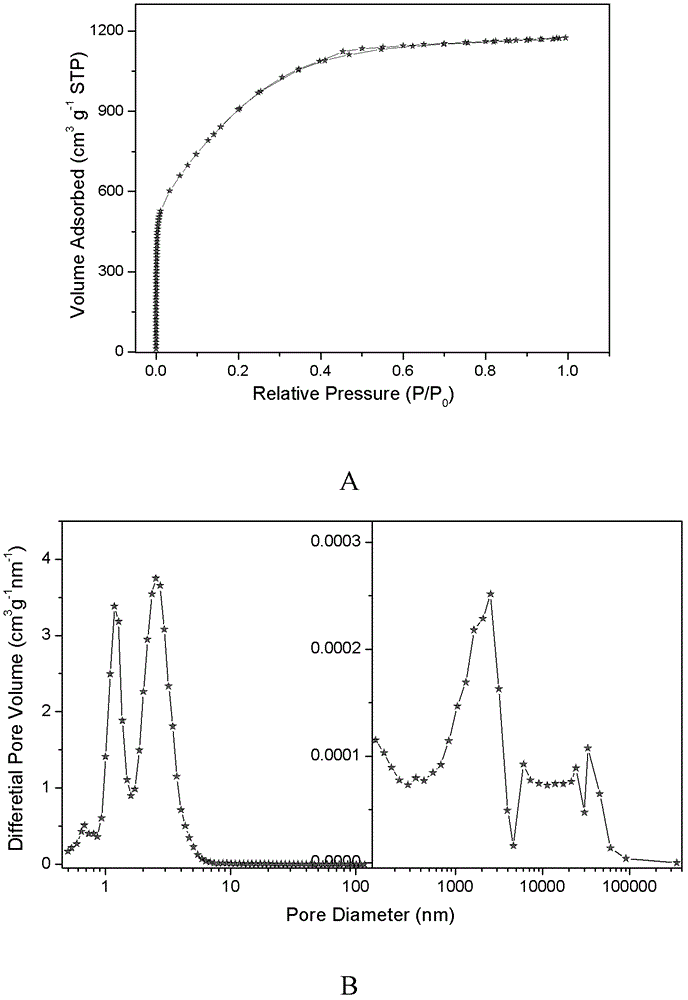

[0035] The specific surface area (BET) of the prepared hierarchical porous carbon fiber material was 298m, tested by nitrogen adsorption method and PoreMaster60 mercury porosimeter produced by American Micromeritics company. 2 / g, the pore volume ...

Embodiment 2

[0039] The steps of preparing high specific surface area hierarchical porous carbon fiber material with sisal fiber as raw material are as follows:

[0040] (1) 5g KOH is dissolved in the solvent obtained after mixing 10ml water and 6ml absolute ethanol to obtain a solution containing etchant KOH, then 1g of the hierarchical porous carbon fiber prepared in Example 1 is added, fully stirred, and the The mixture was dried at 100°C for 6h;

[0041] (2) The dried mixture was placed in a carbonization furnace, and in a nitrogen atmosphere with a flow rate of 400ml / min, the temperature was raised to 900°C at a heating rate of 5°C / min, and after constant temperature activation for 3h, the temperature of the carbonization furnace decreased to The mixture was taken out at 50°C, and the solution obtained by mixing 100ml of deionized water and 10ml of 37% hydrochloric acid was washed three times under boiling conditions, and once with 200ml of deionized water, filtered and dried at 110°C...

Embodiment 3

[0046] The steps of preparing high specific surface area hierarchical porous carbon fiber material with sisal fiber as raw material are as follows:

[0047] (1) dissolve 3g KOH in the solvent obtained after mixing 10ml water and 6ml absolute ethanol to obtain a solution containing etchant KOH, then add 1g of the hierarchical porous carbon fiber material prepared in Example 1, fully stir, The mixture was dried at 100°C for 6h;

[0048] (2) The dried mixture was placed in a carbonization furnace, and in a nitrogen atmosphere with a flow rate of 400ml / min, the temperature was raised to 900°C at a heating rate of 5°C / min, and after constant temperature activation for 3h, when the temperature of the carbonization furnace dropped to The mixture was taken out at 50°C, and the solution obtained by mixing 100ml of deionized water and 10ml of 37% hydrochloric acid was washed three times with boiling, and once with 200ml of deionized water, filtered and dried at 110°C for 12 hours to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com