Titanium dioxide nano wire microsphere photocatalysis material with hydrogenated surface and preparation method thereof

A titanium dioxide and surface hydrogenation technology, applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen production, etc., can solve the problems of low quantum efficiency of titanium dioxide, surface hydrogenation, etc. The effect of crystallinity and large industrialization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

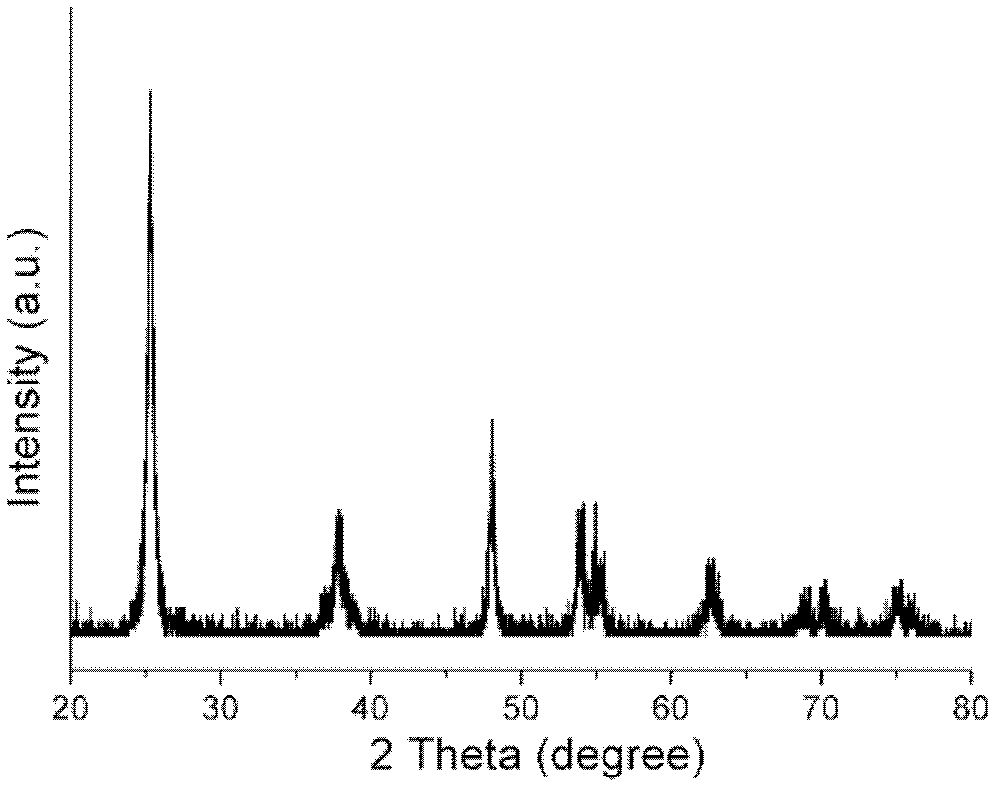

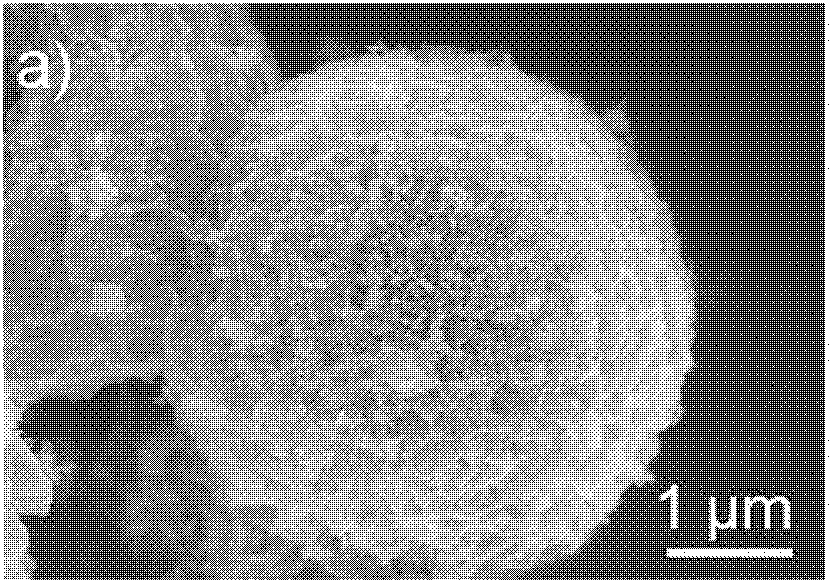

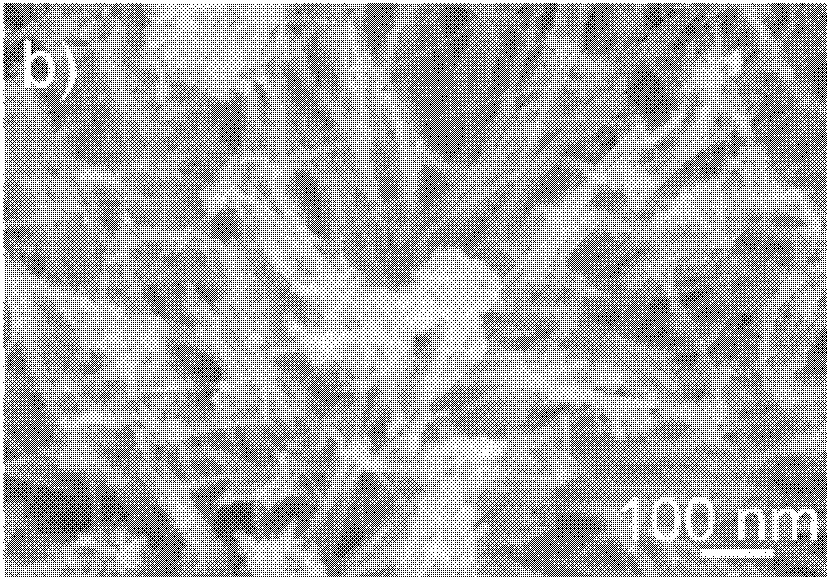

[0030] Firstly, the titanate nanotube microsphere precursor was synthesized by the alkali-thermal method we have reported: 5.1g of tetrabutyl titanate and 75mL of absolute ethanol were mixed together, and then 0.33mL of 98% sulfuric acid and 0.3mL of deionized water. The mixed solution was magnetically stirred for 0.5 h, then transferred to a dry polytetrafluoroethylene-lined stainless steel reactor, heated to 180° C. in a drying oven and kept for 4 h, and the white precipitate in the reactor was collected and dried. Mix 0.5g of precipitate and 50mL of 10M NaOH solution together, transfer the mixed solution to a polytetrafluoroethylene-lined stainless steel reaction kettle, heat to 150°C in a dry box and keep it warm for 24h. Subsequently, the precipitate was collected and dispersed into 600 mL of 0.1 M hydrochloric acid solution, stirred for 12 hours, and then filtered and washed with deionized water until neutral. After the product was collected, the titanate nanotube micros...

Embodiment 2

[0038] First, the precursor of titanate nanotube microspheres was synthesized by the reported alkali-thermal method (same as in Example 1); 0.5 g of the precursor was put into the quartz boat in the center of the quartz tube, and then the quartz tube was placed horizontally into the tubular In the furnace, continuously feed H at a flow rate of 200 sccm 2 Mixed gas (5%H 2 with 95%N 2 ), the tube furnace was raised to 500°C at a heating rate of 3°C / min and held for 4 hours. After the tube furnace was naturally cooled to 150°C, the H 2 , the surface hydrogenated titanium dioxide nanowire microspheres can be obtained.

Embodiment 3

[0040] First, the precursor of titanate nanotube microspheres was synthesized by the reported alkali-thermal method (same as in Example 1); 0.5 g of the precursor was put into the quartz boat in the center of the quartz tube, and then the quartz tube was placed horizontally into the tubular In the furnace, H was continuously introduced at a flow rate of 250 sccm 2 Mixed gas (5%H 2 with 95%N 2 ), the tube furnace was raised to 500°C at a heating rate of 4°C / min and held for 2 hours. After the tube furnace was naturally cooled to 150°C, the H 2 , the product can be collected to obtain surface hydrogenated titanium dioxide nanowire microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com