Catalyst used in preparation of acrylic acid and/or acrylic acid ester from lactic acid or lactate through dehydration

An acrylate and lactate technology, applied in the field of catalysis, can solve the problems of low catalyst stability, inability to meet industrial requirements, and many by-products of lactic acid dehydration, and achieve good reproducibility, good industrial application prospects, and easy process control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

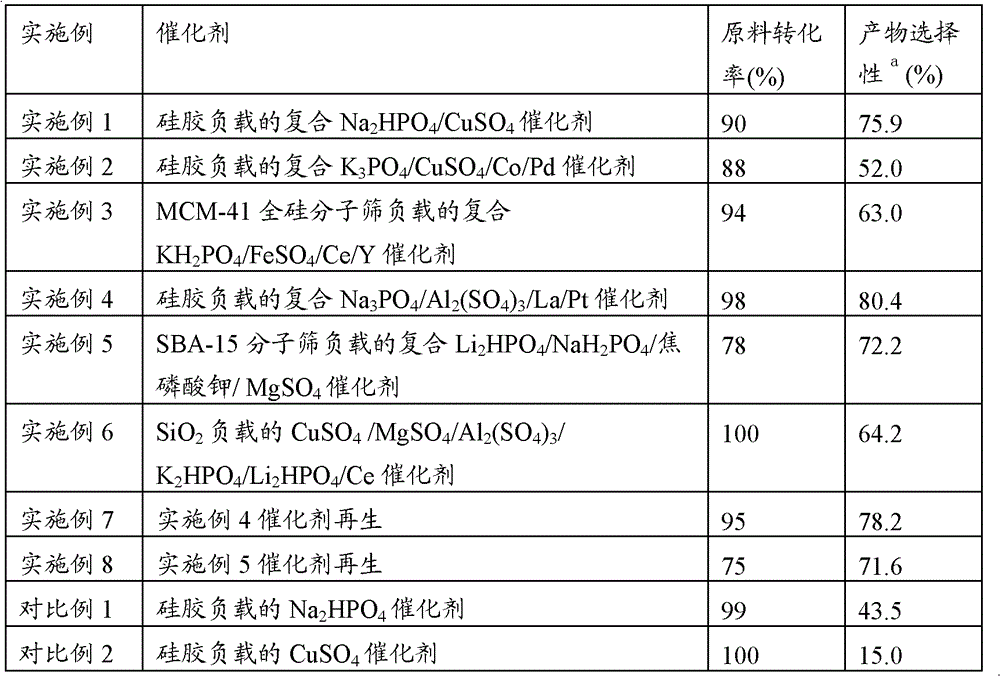

Examples

Embodiment 1

[0040] Catalyst preparation

[0041] First weigh CuSO according to the loading amount of 10wt% 4 , add water to dissolve according to the excess impregnation method, and 5g of dried silica gel (specific surface area 320m 2 / g) was added to the solution; dried at 100°C for 4h, then transferred to a muffle furnace and roasted at 500°C for 3h to obtain CuSO loaded on silica gel 4 Material.

[0042] Then take Na by weighing 30wt% load 2 HPO 4 , add a certain amount of water to mix and dissolve according to the same amount of impregnation method, and the silica gel-loaded CuSO prepared in the above steps 4 The material was immersed; dried at 100°C for 4h, then transferred to a muffle furnace, and baked at 500°C for 3h to make a silica gel-loaded composite Na 2 HPO 4 / CuSO 4 catalyst.

[0043] Catalyst application

[0044] Weigh 2g of the catalyst prepared in the above preparation process, put it into a 8mm×400mm quartz glass tube fixed-bed microreactor, and carry out the r...

Embodiment 2

[0046] Catalyst preparation

[0047] In embodiment 2, this process is different from embodiment 1 in that, by weighing CuSO 4 , using a specific surface area of 200m 2 / g of silica gel; dry at 120°C for 3 hours, then bake.

[0048] Weigh K according to 10wt% load 3 PO 4 , and take the cocatalyst cobalt acetate by 0.5wt% load and weigh Pd(NO by 0.1wt% load 3 ) 2 , add a certain amount of water to mix and dissolve according to the same amount of impregnation method, and then add CuSO loaded on silica gel 4 The material was immersed; after drying, it was baked at 700°C for 2h, and the other reaction conditions were the same as in Example 1 to make a silica gel-loaded composite K 3 PO 4 / CuSO 4 / Co / Pd catalyst.

[0049] Catalyst application

[0050] Example 2 In the same reactor as in Example 1, the reaction of lactic acid dehydration to produce acrylic acid is carried out. The difference between this process and Example 1 is that during the reaction, the concentration...

Embodiment 3

[0052] Catalyst preparation

[0053] In embodiment 3, this process is different from embodiment 1 in that, by weighing FeSO 4 , using a specific surface area of 320m 2 / g of MCM-41 all-silicon molecular sieve; dry at 100°C for 6 hours, and bake at 350°C for 4 hours.

[0054] Then weigh KH by 50wt% load 2 PO 4 , and weigh the cocatalyst Ce(NO 3 ) 3 , weigh the cocatalyst Y (NO 3 ) 3 , add a certain amount of water to mix and dissolve according to the same amount of impregnation method, and then add FeSO loaded on silica gel 4 Material immersion; drying at 100°C for 6 hours, roasting at 600°C for 3 hours, and other reaction conditions are the same as in Example 1 to make a composite KH compound supported by MCM-41 all-silicon molecular sieve 2 PO 4 / FeSO 4 / Ce / Y catalyst.

[0055] Catalyst application

[0056] Embodiment 3 carries out the reaction that ethyl lactate is dehydrated to produce acrylic acid and ethyl acrylate in the reactor identical with embodiment 1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com